How TBS Engineering is going global while retaining its focus on internal culture

As a leader in automated manufacturing systems for the lead battery industry, TBS Engineering (TBS) boasts an ever-evolving global presence and a rich history dating back to the 1960s. It has undergone a remarkable journey and significant change during this time, with the current management focused on creating a positive working culture for its employees.

We delve into conversation with Richard Taylor, Group Managing Director, and Mark Gardiner, Group Sales Director, to explore the company’s commitment to innovation, as well as its vision for a positive company culture and ambitions for the future.

“It all started in 1968 with Thomas Stamp’s vision to supply machinery to the lead battery industry in the UK,” begins Mark. “The business grew steadily, firstly in the UK and then throughout Europe. In the late 80s, Thomas sold the company to a European company, who expanded operations across the globe. Under the stewardship of Laurie Gardiner we received the Queens Award for Export in 1990 and by the turn of the century, we have become the partner to most major OEM battery suppliers to the world’s leading automotive brands.

“Then, in 2002, we were acquired by MiTek Industries and became part of the Berkshire Hathaway Group, which we remain proud to be part of today. We continued on a strong growth trajectory, purchasing the world’s largest provider of battery plate enveloping equipment, Tekmax, in 2004. Based in Oregon, US, we integrated Tekmax’s operations with those of TBS and together launched our HiTek plate enveloping machines in 2006.

“With global expansion still a priority, we formed a joint venture with Digatron in 2009 to manufacture and service equipment in China, and in 2011, established a plate manufacturing presence in North America with the purchase of Cominco.”

Solutions and service

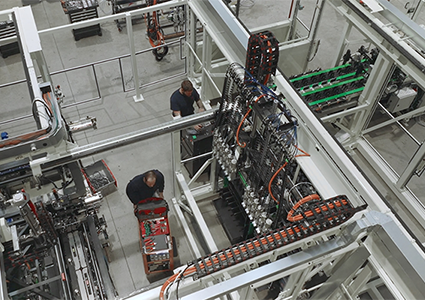

Having grown substantially, the company then turned its attention towards its UK manufacturing operations and continuous innovation. “We first expanded the site in 2014 to meet growing demand, but we eventually relocated to a purpose-built facility in Gloucester in 2018,” Mark narrates. “While we grew in the market of lead battery assembly mainly for automotive customers, we also introduced solutions for reserve power and motive power applications, and also experienced tremendous growth in the niche area of plate and grid making, particularly through the expertise we acquired via Cominco.

“We’re always looking at potential ways to expand our portfolio, but the market is fairly niche. To grow and develop, any business needs volume and thus needs to supply as many customers as possible, therefore it requires us to look further afield if we want to succeed. As a result, we became a global supplier, serving customers from Europe and China to Africa, India, Korea, and Australia.”

Richard explains: “We are further expanding our footprint at the moment, with a warehouse and distribution facility in Mexico and plans in place to secure a location in Germany. We currently have facilities in China, Pennsylvania, and technical support in India, with only around two percent of our business coming from the UK.”

“However,” Mark interjects, “the UK is home to our headquarters, and our manufacturing focus remains here too. We design and manufacture in-house, and that is not set to change in the foreseeable future, but our commitment to customer service and support means we must have strategically located offices dotted around the globe.

“However,” Mark interjects, “the UK is home to our headquarters, and our manufacturing focus remains here too. We design and manufacture in-house, and that is not set to change in the foreseeable future, but our commitment to customer service and support means we must have strategically located offices dotted around the globe.

“That’s the key to our success; we not only provide best-in-class equipment, but ensure that the equipment runs reliably, reduces lead times, keeps operating efficiency high, and gives the customer the output and quality they need.”

Cultural changes

Recently, Richard and Mark have strived to change the working culture to create a more positive and supportive atmosphere for employees. “I stepped into the role of Managing Director earlier this year, and one of my primary goals coming into the position is to make us, if not the best, then one of the best engineering employers in Gloucestershire and beyond,” says Richard. “We’ve revisited our core values and purpose to realign them with where we want the business to go, and we’ve introduced ‘360 reviews’ to regularly identify the training needs of our employees.

“We also run a very successful apprenticeship scheme introduced by my predecessor, David Longney ten years ago, and the vast majority of our former apprentices are still with us and have progressed to more senior roles. One of my plans is to double or even triple the intake of apprentices over the next couple of years, as well as introduce a graduate program. We’re also becoming a much more flexible employer, which is also helping to anchor our cultural changes.

“It’s definitely changing for the better; we want to be a fun, innovative, and collaborative place to work, and that’s why we want a more varied workforce,” Richard continues. “As a dynamic and global company, there’s some great opportunities within the business, especially for travel, which gives young people entering the business a chance to meet new people and immerse themselves in different cultures.”

Mark adds: “We are fortunate that we have a progressive parent company in Marmon Industries, that supports us in changing our culture for the better. From the mechanics and electronics to the software and technologies we use, our diverse engineering disciplines make us an exciting place to work, and we have a great team of people to help us continue on that journey.”

Enhanced efficiency

Despite TBS’ transformative evolution, the lead battery itself hasn’t changed much at all. “There’s been a slight change in manufacturing requirements as the automotive industry has moved away from starting, light, and ignition (SLI) batteries and towards the latest absorbent glass mat (AGM) battery,” Mark explains. “These batteries are required for start-stop automotive applications. The main focus over the last ten-to-15-years has been automation and high-speed production, as well as, of course, health and safety in the manufacturing area with improvements in ventilation and extraction.

Richard adds: “Internally, as the operations have grown, we’ve gone from a small workforce to a much larger one, which has required us to implement a rigorous process control system. My predecessor, David Longney, saw the need for modernization, hence he introduced an ERP system in 2017 and moved us to our current facility with 80,000 square feet of manufacturing space.

“Personally, I was brought into the company four-and-a-half years ago to examine continuous improvement and lean manufacturing,” he reflects. “We’ve rearranged the factory to make product flow all the way from supply chain through to manufacturing and testing. It was a transitional period of two-to-three years that has enabled more efficient processes and bolstered our position in the industry.”

Growth strategy

Despite little change in the market, TBS has continued its path of innovation. “We’ve introduced various technologies to our machine ranges to increase both efficiency and reliability,” Richard informs us. “Key to our vision over the next five years is to keep innovating and looking at Industry 4.0 adoption so that we can offer customers predictive maintenance, cloud-based computing and data processing.

“I’d like us to be in a position to offer remote maintenance too. We’re looking at state-of-the-art augmented reality technology to enable us to carry out real time maintenance support from our facilities, saving both us and our customers time.”

As conversation naturally turns towards the future of the business, Mark reveals: “We’re currently working out our five-year-plan and visualizing where we want to be by that time. At the moment, if our plan is successful, it would take our turnover from $60 million to more than $100 million. Ultimately, we’re a relationships company that strives to create longstanding relationships, resulting in long-term prosperity for both us and the customer.”

Richard concludes: “Our global footprint will see us continue to serve the whole lead battery assembly industry, potentially moving into different battery or energy storage chemistries in the future. Beyond that, we’re constantly innovating to cement our position as the number one supplier in the world and ensure we continue to dominate the market.”