Industrial Robot Safety Gets a Major Upgrade with ISO 10218 Changes

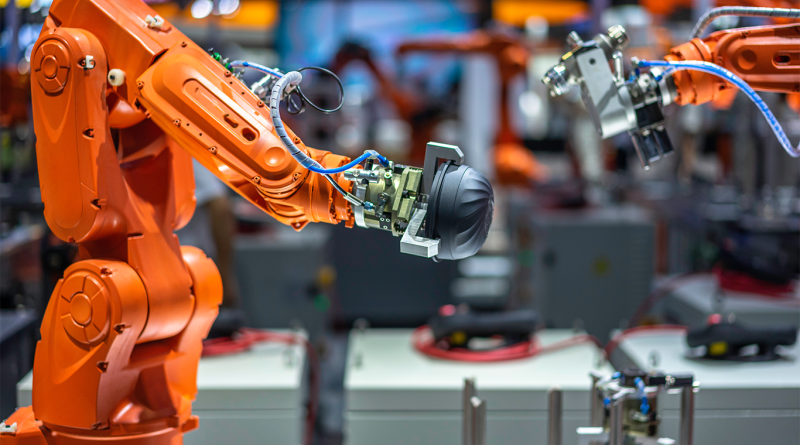

Industrial robots have transformed manufacturing by increasing efficiency, precision, and scalability. However, as automation continues to advance, ensuring worker safety remains a top priority. The International Organization for Standardization (ISO) has recently revised its flagship standard for industrial robot safety, ISO 10218. This marks the first major update since 2011 and aims to address modern safety concerns, from functional safety to cybersecurity in robotic systems.

ISO 10218 sets essential safety guidelines for robot manufacturers and integrators, helping businesses comply with international safety regulations while mitigating workplace risks. With this latest revision, manufacturers must adapt to stricter safety requirements, particularly as robots become more interconnected and collaborative.

Major updates in ISO 10218

The revised ISO 10218 consists of two parts:

Part 1: Safety Requirements for Industrial Robots (Manufacturers)

Part 2: Safety Requirements for Industrial Robot Applications and Robot Cells (System Integrators)

The update introduces several crucial changes that aim to enhance the safety, clarity, and applicability of industrial robot standards. Below are the most notable updates:

Clarified Functional Safety Requirements: The new standard offers more explicit guidance on functional safety, ensuring that manufacturers meet stricter risk assessment criteria. This update enhances the ability of integrators to design safer robotic systems with well-defined fail-safes and hazard mitigation measures.

Integrated Safety Requirements for Collaborative Robots: Collaborative robots, or cobots, are increasingly used in manufacturing. The revised ISO 10218 now consolidates safety guidelines from ISO/TS 15066, which was previously a separate technical specification, providing clearer safety measures for human-robot interaction.

Enhanced Safety Guidance for Manual Load/Unload Procedures and End-Effectors: The new standard incorporates insights from past technical reports (TR 20218-1 and TR 20218-2) to improve safety around manual operations and end-effectors, such as grippers and welding tools.

New Robot Classifications and Safety Testing: The update introduces a refined classification system for industrial robots, along with corresponding safety test methodologies. This change allows for a more tailored approach to ensuring compliance across different robotic applications.

Cybersecurity Considerations: As industrial robots become increasingly connected to networks, cybersecurity has emerged as a vital concern. The new standard includes safety measures to address potential cyber threats that could impact robot functionality and worker safety.

Adoption of the revised standard in North America

The revised ISO 10218 will influence industrial robot safety regulations across North America, particularly through its adoption into existing national standards:

United States (ANSI R15.06): The American National Standards Institute (ANSI) is working to align its R15.06 standard with the new ISO 10218. This process will ensure that US manufacturers follow updated functional safety and cybersecurity protocols.

Canada (CSA Z434): Similarly, Canada’s CSA Z434 standard is being revised to incorporate the updated ISO 10218, ensuring uniform compliance across North American industries.

The timeline for full adoption remains in progress, with industry leaders advocating for businesses to begin aligning their safety protocols immediately. Compliance with the revised standards will not only be mandatory in the near future but will also reduce liability risks and improve worker safety.

For manufacturers and system integrators, the updated ISO 10218 presents both challenges and opportunities. Companies must reassess their current robotic safety protocols to ensure they meet the new requirements. This may involve updating risk assessments, safety documentation, and worker training programs.

New testing methodologies and cybersecurity guidelines may require investments in updated sensors, AI-driven monitoring systems, and advanced safety barriers to ensure compliance and safety.

As industrial automation continues to evolve, the next decade will bring further advancements in robotic safety standards. Future updates to ISO standards may place even greater focus on ensuring the safe coexistence of humans and robots, expanding on the principles of collaborative robotics.

Sources:

- International Organization for Standardization (ISO) Part 1

- International Organization for Standardization (ISO) Part 2

- Association for Advancing Automation (A3)

To keep up-to-date with our latest manufacturing news, subscribe to our newsletter today.