Innovation and independence underpin American Battery Factory’s success, as it takes on major new projects

Energy is everywhere, and it’s always changing. Providing safe, sustainable battery cell storage for a rapidly evolving energy supply sector has established American Battery Factory as one of the foremost large-scale manufacturers in the US. As ABF President, John Kem, begins: “The company grew out of the demand in recent years for energy storage solutions and the necessary battery pack production. Lion Energy was well-established in the energy space when the leadership team decided to branch out into battery solution components. Battery packs are made up of hard-to-come-by materials, for most companies, anyway. But we were already working with most of the necessary resources through the battery pack side of the business, although many were unavailable at any real scale inside the US. So, we decided to split off, and start making battery cells – which are the most fundamental part of a battery pack. We are driven to insource our procurement and manufacturing back into the US and North America, and that’s how American Battery Factory was born.

“Much of our leadership team comes from Lion Energy, including our CEO, Jim Ge, and our CFO, Tyler Hortin. Even though American Battery Factory is a completely separate entity now, our team has strong experience working in the energy sector. The goal was to bring large-scale manufacturing back to the United States. Unfortunately, so much of the manufacturing industry has moved overseas, with the exception of pharmaceuticals and defense systems. We thought, if they can do it, why can’t we?

“We have brought in and continue to seek as much expertise as possible from across North America, Canada and even Europe. With such an experienced, dedicated team behind us, we’re building a truly high-end, innovative manufacturing process. The proof is in the product – we offer something different, unique, and powerful.”

Precision processes

The overall mission of American Battery Factory is to recognize and become an integral part of the global energy transition. “We are seeing lots of innovation when it comes to energy production, but the grid and distribution systems are not ready – most will take decades to expand and modernize – so energy storage solutions are truly essential. The battery storage solutions we are now producing are extremely different to anything we’ve done in the past.

“We want to be able to produce powerful energy solutions here at home. Demand throughout the manufacturing supply chain is complex. We’re learning as we go, because lots of our work is on brand-new technology. We’re happy to be a part of the innovation process, as the industries that we serve work out the right applications for our product. It’s actually a lot of fun,” John enthuses.

Battery cell production is no small-scale operation, as John details: “Our initial two by 2GWh manufacturing lines are very large industrial units; they are almost two thousand feet long. In the US, about the only comparable is the old paper mills from the ’50s to ’70s. The buildings are long and thin, and the inside is all open plan with lots of access space around the equipment, which includes high end process automation and is manned by a highly skilled workforce. It’s not necessarily complicated, just different to what people are used to in the manufacturing industry in the US today. Each machine costs around $100 million, to give you an idea.

“There are around eight or nine main machine components in our manufacturing process. The early part is the chemical mixing, where we bring all the raw materials together and blend them. Once the mixture is well-balanced, we move on to create the electrolyte solutions. Within that, there’s a variety of complex chemical reactions happening.

“Our work is highly specialized and requires a strong understanding of high-end computer-controlled chemical, electrical and mechanical processes. That’s why we are partnered with Pima Community College and other local universities. They will offer training programs for talented young people, who can seek training and certification with our and related high end manufacturing technology. It’s a really great partnership for us; the students get to learn, and we can grow our talent pool. After all, these are high-end machines, and their margin for error is pretty small, so we need people who really understand the processes going on inside to run them. It is a unique opportunity to teach and learn how to identify, very early in the process, things like machinery faults, chemical imbalances in the mixture, optimized recycling and other essential skills that set them up for a career in the energy manufacturing sector.

“Our work is highly specialized and requires a strong understanding of high-end computer-controlled chemical, electrical and mechanical processes. That’s why we are partnered with Pima Community College and other local universities. They will offer training programs for talented young people, who can seek training and certification with our and related high end manufacturing technology. It’s a really great partnership for us; the students get to learn, and we can grow our talent pool. After all, these are high-end machines, and their margin for error is pretty small, so we need people who really understand the processes going on inside to run them. It is a unique opportunity to teach and learn how to identify, very early in the process, things like machinery faults, chemical imbalances in the mixture, optimized recycling and other essential skills that set them up for a career in the energy manufacturing sector.

“Due to the nature of our process, it’s important to catch any errors early on, otherwise we’re left with waste material. We’ve refined the early stages so that we can monitor the chemical mixture closely and amend any deviation from the formula before it reaches the cell stage. Any waste is minimal enough that we can recycle it. Our people are taught to be analytical and critical, so that they can make smart, strategic decisions in the moment. That is what we think is the real opportunity with ABF as a US-based company; we bring that high-end decision making to the manufacturing process that you might not see in other places.”

Positive impact

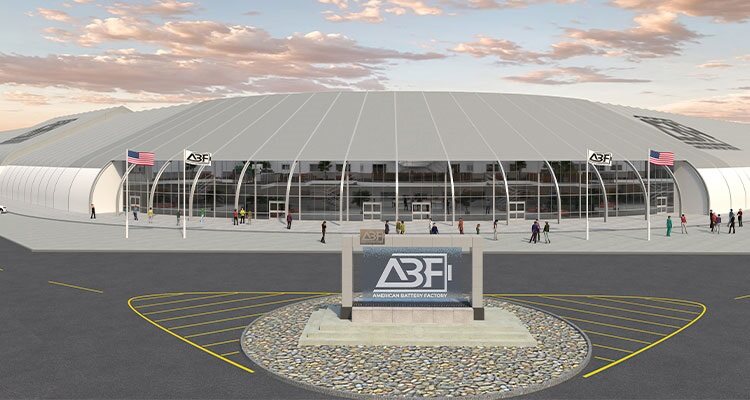

In November 2023, American Battery Factory broke ground on the largest lithium-ion phosphate cell manufacturing facility in the US. The site will provide over $1.2 billion in economic impact, as John affirms: “Our new manufacturing site will have a hugely positive impact on the local community. Aside from our work with Pima Community College, the construction of our factory will bring over 600 jobs to people in surrounding areas. Once it’s up and running, the first four-gigawatt line will generate another 300 jobs because it will be operating 20-to-24 hours a day, seven days a week.

“Shortly after we finish up the first battery line, we will then kick off the next three buildings. Eventually, we’ll be producing around 17-to-18 GWh of battery cells annually across the site, requiring three-to-four times the initial workforce, which is pretty substantial. We have partners who are interested in new investments and synergies, because they are seeing how rapidly the business is expanding. We’ve even had some recycling experts reach out to us to discuss a regional recycling project, which sounds incredibly rewarding. We really can’t wait,” he concludes.