JobPack

But that attitude has shifted in the past decade as integration has become easier and customers realized they needed features and capabilities only a dedicated platform could provide. “What you see now is people realize there isn’t one complete system that is going to do everything you need in a manufacturing company,” says Peter Welsh, president of JobPack, an Illinois-based company that develops production scheduling and management systems.

ERP systems contain many different modules designed to connect with the system as a whole, but in many cases those individual modules are not the most effective software for that task. Companies excited about the possibilities of implementing an ERP system may be disappointed once it goes into practice. “Either it’s not robust enough, they can’t adapt it to what they’re doing or when they want to use that ERP to schedule they can’t,” Welsh says.

JobPack solves the scheduling component. “Our main focus has always been scheduling,” he continues. “Even though other systems may do some of those things, they might not be user-friendly. After 20 years of focusing just on scheduling, there aren’t many scenarios we haven’t come across from a manufacturing standpoint.”

ERP Integration

When choosing an ERP system, manufacturers should consider three attributes: adaptability, efficiency, and cost. Welsh believes that ERPs can only deliver in two of those areas at once. Companies can install a highly adaptive system with a great amount of efficiency, but the time it takes to develop such a custom system can cost millions of dollars. Conversely, an off-the-shelf ERP system is lower cost, but it probably won’t offer the same level of integration and flexibility as one built from the ground up.

One of the features that can suffer from an all-encompassing ERP is the production timeline because ERP systems typically approach scheduling from the financial perspective. To hit the  profit margins the company wants, salespeople might build extra time into the manufacturing process. A job that only takes one hour of production might instead be quoted for one-and-a-half hours. However, when that data is relayed to the shop floor the estimated times don’t match reality.

profit margins the company wants, salespeople might build extra time into the manufacturing process. A job that only takes one hour of production might instead be quoted for one-and-a-half hours. However, when that data is relayed to the shop floor the estimated times don’t match reality.

The company’s production management software retrieves information from the ERP system, then allows the shop floor to adjust those scheduling times without changing the root values stored in the ERP database. “The advantage with importing data from an ERP system is the customer can pick and choose what they want to import,” Welsh says, “but the customer can also manipulate that data when it comes over.”

The data JobPack collects and distributes includes work order, production amounts, deadlines, routing information and the necessary manufacturing steps and processes. The system itself is modular, so customers purchase only the components they need. One client may want to connect the scheduler to its CNC machines to implement paperless manufacturing while another requires only cloud-based reporting. Whatever the use, JobPack customizes the software to fit that application.

Real-Time Feedback

As manufacturers strive to get leaner every day, they want to see into the future. Forecasting often deals with anticipated demand, but scheduling is an equally important but sometimes overlooked part of the process. Many jobpack1manufacturing issues can be resolved just by having complete insight into the production schedule, Welsh says.

Proper scheduling informs companies when they should begin production on a job and what materials they need to stock to complete a run. Having accurate scheduling information ahead of time allows employees to pick the proper stock ahead of time or proactively order whatever parts are needed so that production can begin seamlessly.

“The benefits you are going to see and what a lot of customers realize once they really get into looking at scheduling, is when you can schedule accurately it resolves a lot of other issues in the shop as well,” Welsh says.

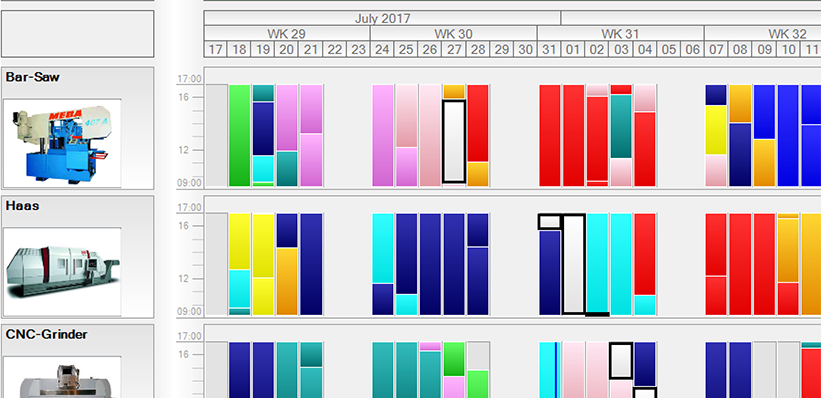

JobPack’s software handles all of those scheduling duties automatically. Customers define their resources – the machines and materials they have on hand – and JobPack pulls from the ERP to identify orders, then fills out a timeline of jobs ready to enter production. The software maximizes the efficiency of the plant, ensuring that any operable machine is put to work and scheduling only those runs that have prerequisites met to avoid idling. “We’re trying to get out more work in the same number of working hours,” Welsh says.

Like its other components, the schedule generated by JobPack is modifiable. If a customer calls screaming that they want a job expedited, the manufacturer can drop that into the scheduler to see how it shifts the rest of production in real time. The system visualizes the ripple effect on the schedule, listing what orders will have to be bumped and even alerting the customer as to what items could miss their deadline – even if those production runs are still several weeks away. “You can do these scenarios to see where it’s going to impact your schedule,” Welsh says.

Although the system finds efficiencies and eliminates idle time, Welsh warns that there is no magic button customers can press to ensure that every order is produced on time within a limited working period. However, JobPack’s system will show what can be done on time and what will be delayed, helping companies make decisions on whether to add more hours or shifts, or even invest in another machine.

The desire to build a system that fits a client’s unique requirements extends to training. Instead of using web-based classes or generic examples to teach customers how to use the scheduling system, JobPack goes to the client’s facility and demonstrates how the software works in real-world applications. The company’s trainers teach the system using the client’s own data, ensuring that they can relate the training to their own processes.

Training lasts two to four days and by the end the customer already has the initial production schedule set up. From there, they simply need to build new orders into the production timeline. “We want to train you in your environment because it’s always a little different,” Welsh explains.