Kannegiesser UK

Effortless laundry

One of the largest manufacturers of laundry technology in the world, Kannegiesser GmbH has continued to innovate and invest in the last three years to maximise the opportunities presented by the favourable business climate in Europe, Asia, and North America

In today’s business world, automation is increasingly growing in significance, with more companies recognising it as an opportunity to reduce costs in their bid for a competitive advantage  within their respective industry. Riding the wave is Kannegiesser UK – the global leader in the provision of automation solutions for the industrial laundry sector. Three years after its first appearance in Manufacturing Today Europe, the company makes a return, and its Engineering Director, Dr Paul Morley is happy to discuss how life has been for Kannegiesser UK during this period.

within their respective industry. Riding the wave is Kannegiesser UK – the global leader in the provision of automation solutions for the industrial laundry sector. Three years after its first appearance in Manufacturing Today Europe, the company makes a return, and its Engineering Director, Dr Paul Morley is happy to discuss how life has been for Kannegiesser UK during this period.

“The company’s turnover in the last three years has increased quite markedly and we can report with satisfaction the buoyancy of our export business, both in and out of the EU,” Paul begins. “We find especially good markets in the countries with growing economies, who now offer higher wages and make the need for automation more tangible. For example, many countries in Eastern Europe have worked hard in recent years to attract foreign businesses to open local offices, which has had a positive effect on their economies, also creating a good market for new automation.”

About 25 per cent of Kannegiesser UK’s turnover is generated in the UK, other traditionally strong markets being Germany and France. “Besides,” Paul reports, “the Far East, especially Singapore and Malaysia, is faring exceptionally well at the moment. The parent company, Kannegiesser GmbH also strengthened its business in North America in 2016, when it bought a company in the USA that manufactures a similar materials handling product to ours. The two organisations are now working together under the same group, collaborating on R&D matters to develop the system of the future, and I envisage even closer co-operation between the two in the coming years.”

Paul cites the improved hygiene culture across the society as another key driver of growth for the business. “A general trend is that people now expect higher standards of cleanliness and hygiene all the time. As a result, items need to be washed more frequently to meet the rising requirements. Couple this with the aforementioned trend of higher wages, which makes everyone more mindful of the need to automate, and you can see why a company like ours, who is in the business of providing equipment and solutions for automation and materials handling, is experiencing such a strong growth,” he reasons.

Favourable market conditions, however, tell only part of the story. Reaching the heights Kannegiesser UK has soared to, would have been impossible without the continued and well-measured investment in the development of its manufacturing processes, machinery, innovative practices, and, of course, people. “We have added new equipment and attracted new workforce in the last couple of years to add to the strength in depth of the company. Right now, we are trying to bring a lot of our manufacturing in-house to gain more direct control over the quality and the timescale of our products,” Paul points out. “To this end, we are looking at enlarging our floor space and purchasing more new equipment, which will create more opportunities for our employees to develop their careers within Kannegiesser. We have already had people moving from entry-level assembly positions into more skilled jobs, and then onto design, R&D, or programming positions, which is definitely the positive direction the company is headed to.

“Innovation is another essential part of our success,” he continues. “We have a strong R&D team working on a range of new products, such as the recently launched robotic hoist with servo technology, which is faster, stronger, and quicker to install than the previous hoist. This is part of our portfolio of new products, which will link to the idea of developing a system with more intelligence, the ultimate expression of which will be a self-optimising, self-maintaining logistic system, that we are aiming to create and introduce to the marketplace.”

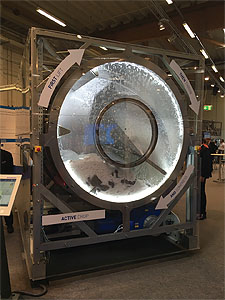

For Kannegiesser to demonstrate its wide range of innovations, products, and solutions in their entirety, the company held a private exhibition in June 2018 to a selection of personally invited attendees, where 75 machines and systems were installed across 5000 square metres of exhibition space. “The EXPO 2018 focused on six main areas: data management of the ‘smart laundry’; increased machine performance; increased machine availability; development of robotic laundry production; increased ability to process a large variety of differing laundry items; and, conservation of resources through decreased energy and water usage,” Paul reveals.

“We wanted to encourage customers to look into the future of the laundry processing. The search for sufficient personnel to operate machinery is becoming increasingly difficult for many of our clients, hence the importance of developing robotics to undertake production steps. To give you an example, a prototype using robot-controlled soiled laundry sorting was demonstrated alongside the conventional, but ergonomically redesigned sorting station by Supertrack. Bearing in mind that up to 60 per cent of all personnel activities are related to sorting and separation, there is a pressing need for automation of the process, and we want to be at the forefront of its development,” states Technical Marketing Operations Manager, Matt Schäfer.

“One of the major challenges for Kannegiesser is that there are smaller companies in our market who promise much, but often compromise on the quality and safety standards of their products. This makes them cheaper in the short term, and this proves an attraction for some customers. It is only later on that they come to regret buying cheaply, but by then we’ve lost the business. We take the highest safety standards as a minimum and are determined to continue this way. Our objective is to maintain the highest quality of the products we manufacture and demonstrate even more advanced innovation. We have a rich portfolio of product ideas to develop that will help us remain the trustworthy leader in our sector,” Paul concludes vigorously.

Kannegiesser UK

Services: Industrial laundry technology