Leggett & Platt Components Europe Ltd

Springboard to success</strongb

Leggett & Platt Components Europe Limited is a leading designer and manufacturer of innersprings for the bedding industry – and is always striving to improve its products

Leggett & Platt Components Europe Limited is part of the International Bedding Components Division of Leggett & Platt Incorporated. This company is 133 years old and made up of 17 business units, 20,000 employee-partners and 130 facilities located in 19 countries. Further information about Leggett & Platt was provided by managing director Darren Rhodes: “Formed in 1998, the International Bedding Components Division strategically positions Leggett & Platt as the largest supplier of innerspring components to the bedding and furniture industry within Europe, South Africa, the Middle East, and Asia-Pacific.”

According to Darren, being part of Leggett & Platt strengthens the company in a number of ways. “Being part of the largest innerspring unit manufacturer in the world allows us to share knowledge and tap into the many innovative ideas that come from our corporate IDEA Centre and all the other plants around the world. We have our own world-class machinery division that supplies much of the manufacturing equipment we need and probably, most importantly, Leggett’s willingness to continue to invest in growing our business.”

According to Darren, being part of Leggett & Platt strengthens the company in a number of ways. “Being part of the largest innerspring unit manufacturer in the world allows us to share knowledge and tap into the many innovative ideas that come from our corporate IDEA Centre and all the other plants around the world. We have our own world-class machinery division that supplies much of the manufacturing equipment we need and probably, most importantly, Leggett’s willingness to continue to invest in growing our business.”

Crucial to any business in the manufacturing market is the facilities it uses, and this is a feature of Leggett & Platt that is very strong, and something Darren elaborated on: “We have two plants in the UK; the main plant in Barnsley which focuses on the production of pocket spring units whilst Barnoldswick produces open-coil type units, specifically Mira-Coil for Silentnight – a company that we have had a very long and very successful relationship with, that has benefited both companies’ growth. Leggett & Platt’s two factories in the UK produce over 30,000 tonnes per year of our own wire that we then use in the production of the innerspring units. Both sites have full supply chain capability from receiving raw materials, production, quality and testing facilities, finished goods warehousing, dispatch and customer service.” The scale of Leggett & Platt’s two facilities means that over the course of a week it will produce over 30 million springs.

There are plans to improve what the business can do even further, which Darren discussed: “We have invested approximately 18 million pounds in machines, facilities, and warehousing in the last four years, a trend we plan to continue. We employ 20 per cent more people than we did two years ago and have invested over 100,000 pounds in learning, development, and training for our employees in that time.”

The company wants all of its customers to be happy with the products it makes, and Leggett & Platt does not achieve this by any one means; instead it takes a multifaceted approach, which Darren explained: “We focus on innovation, customer service, consistent high-quality products and commitment to continuously improve everything we do. People are a big part of it – anyone can buy machines and buildings, but it’s the people and relationships that make the difference.”

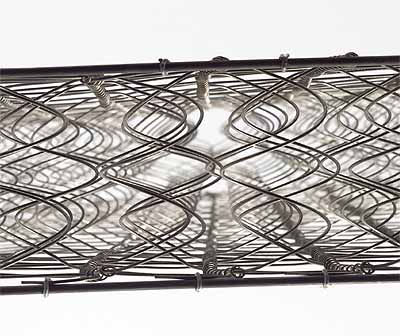

One of the overwhelming features of Leggett & Platt is innovation, and Darren provided some instances of this: “Since we have the ability to design and build our own machines it gives us a major advantage and keeps us at the forefront of spring-making technology. We manufacture heat-treated springs at a rate of over 140 springs per minute from 25mm high to 200mm high, which can be used in the core and comfort layers within a mattress, allowing us to make a single spring unit with over 4,000 springs in it. Another innovation is our variable-rate springs that offer different levels of progressive support and pressure distribution within the spring unit and hence mattress, depending on the load applied; this creates a very comfortable and independent-feeling mattress for lighter and heavier people on the same bed.”

There are also developments being made at the company, which makes it evident that the business is forward-thinking, and Darren provided some examples of ways Leggett & Platt is pursuing this approach: “We have just installed five state-of-the-art advanced pocket-coiling machines and plan for six more over the next six months. These are among the fastest and most efficient coiling machines in the world and will allow us to make more ergonomic pocket units with reduced environmental impact. We are also due to take the first of its kind continuous coil machine in Q4. This machine is a brand-new development made by our Swiss sister company which produces a type of open coil spring unit like no other.”

Leggett & Platt has already achieved so much, and yet the company has its eyes firmly set towards the future. Leggett & Platt knows exactly what it wants to achieve and how it will do that, something that Darren concluded with: “We deliver to our customers the capacity, technology, innovation, and service levels they need. Which is why our focus for the future will be to become the first-choice supplier of innersprings for the bedding industry – and we will do this by continuing our policy of pursing investment, service, improvement, and developing our people. With a focus on quality, cost, and service, we have built and will further advance strong and long lasting relationships with our customers, suppliers, and employees, and will continue to invest for the long-term benefit of all.”

Leggett & Platt Components Europe Ltd

Products: Innerspring components