Leveraging decades of expertise and a robust technology portfolio, TriMech ensures manufacturers achieve faster, smarter, and more cost-effective production

With more than 35 years of industry experience, as a collection of established brands, TriMech Group provides internationally recognized design, engineering, and manufacturing solutions and services to clients in the US, Canada, the UK and Ireland, and Europe’s Nordic regions.

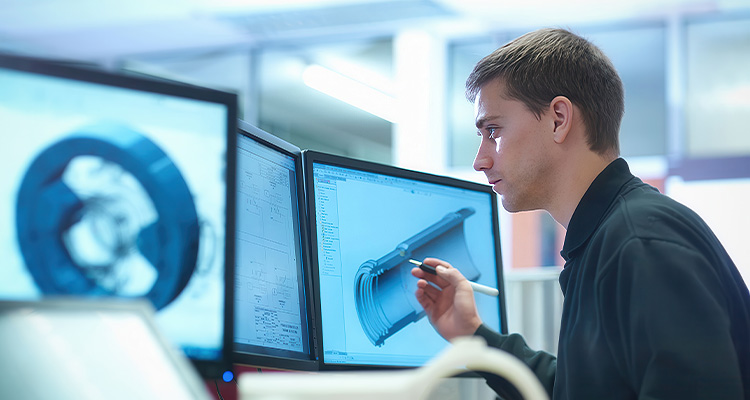

“Our global team includes hundreds of engineers who excel in areas including design, collaboration, simulation, analysis, process and workflow optimization, product data and lifecycle management, manufacturing, and production floor solutions. We also offer training, support, and consulting services,” shares President of Advanced Manufacturing, Chip Hogge.

As a technology and business solutions partner to its clients, TriMech works with top software and hardware partners, including Dassault Systèmes, SOLIDWORKS, Stratasys, One Click Metal, Artec, and Zeiss. The company operates across more than 50 locations and serves more than 30,000 clients with 750 employees.

Chip explains that TriMech was founded in the late 1990s (as were some of its legacy entities) to provide SOLIDWORKS CAD solutions and support. “Over the years, we have continued to adopt leading engineering technology and added advanced manufacturing solutions. These include 3D printers, 3D scanners, and a range of services.”

Chip explains that TriMech was founded in the late 1990s (as were some of its legacy entities) to provide SOLIDWORKS CAD solutions and support. “Over the years, we have continued to adopt leading engineering technology and added advanced manufacturing solutions. These include 3D printers, 3D scanners, and a range of services.”

Growth by strategic acquisitions

In the US, up to 2020, TriMech grew organically and expanded its SOLIDWORKS and Dassault Systèmes client base by acquiring several SOLIDWORKS partners. TriMech then acquired Javelin Technologies in Canada in 2021, and Solid Solutions in the UK and Ireland in 2022.

A comprehensive acquisition strategy has contributed to TriMech Group’s current position as an industry leader. Chip highlights a range of advanced manufacturing offerings: “Our hardware portfolio includes 3D polymer printers from Formlabs and Stratasys, laser powder-bed fusion metal 3D printers from One Click Metal, and a range of other professional and desktop printers used in research, development prototyping, and production applications. These systems are used by our automotive, aerospace and defense, medical, consumer products, and manufacturing clients.” Partnerships with Artec, Zeiss, and several other 3D scanner suppliers help support clients’ reverse engineering, measurement, and quality and inspection processes.

A focus on services

Providing timely services and support helps TriMech stand out. Chip notes: “In addition to providing training and consultation services to support software and hardware products, our global team of experts has the knowledge and experience to provide design, engineering, and simulation services. We also offer advanced manufacturing services to accelerate clients’ product development processes or provide additional production capacity.”

Metal additive manufacturing

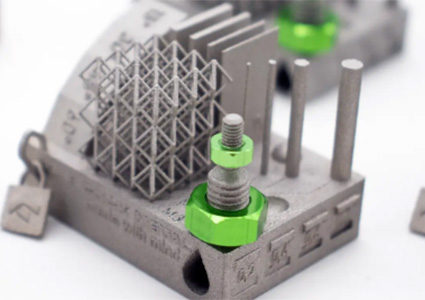

TriMech now offers One Click Metal’s BOLDSERIES as a cutting-edge 3D printing solution. Metal 3D printing is a priority growth area for TriMech in the continually evolving 3D printing landscape. In-house metal printing is less costly than traditional milling production and can reduce production time from weeks to days.

One Click Metal’s MPRINT printer has the largest construction area in its performance range, making it flexible for a range of applications. Material options include stainless steel, nickel alloy, aluminum, and titanium, with a modular add-on allowing operators to use a smaller amount of different powder materials for research, development, and education.

stainless steel, nickel alloy, aluminum, and titanium, with a modular add-on allowing operators to use a smaller amount of different powder materials for research, development, and education.

Clients are finding more, and increasingly diverse, uses for 3D-printed metal parts. “Applications include tool making, mechanical engineering, medical and dental, automotive, aerospace, defense, education, and jewelry making,” Chip shares.

Expansion and diversification

An ongoing dedication to innovation means TriMech is always at the top of its game. “Our deep in-house technical expertise across manufacturing verticals allows us to continue investing to execute our strategy of being the best-in-class solution partner to the global advanced design, engineering, and manufacturing sectors,” Chip adds. “Our clients do complex and critical work, and our goal is to simplify that complexity to help them improve their processes, results, and profitability.”

Having made a strong start to the year, Chip considers what else 2025 has in store. “We will continue to focus on providing solutions to businesses across North America and Europe. As traditional methods of manufacturing change with new technology advancements, we have a unique opportunity to help our clients streamline their processes and get their products to market faster.”

As for TriMech’s 3D printing portfolio, the team is focused on helping clients “cross the chasm” from using additive manufacturing for development and prototyping applications into printing for production.

“We do this by offering reliable, scalable solutions from our key partners Stratasys, Formlabs, and One Click Metal, supported by training, services, and support,” he elaborates. Over the last several years, TriMech has successfully broadened its portfolio to offer more relevant and valuable solutions to clients across several key verticals. “Our growth strategy aims to expand our addressable market and scale our service offerings to help our clients manufacture their products faster, at lower cost, with higher quality and lower risk.”

Looking even further ahead, Chip expects that TriMech Group will have firmly established itself as the premier partner to a range of manufacturing clients across the globe. “Our unique portfolio of products and services will ensure we continue that growth trajectory. We’ll add new clients, retain existing clients, and strengthen our relationships by serving as a trusted advisor for their most challenging design, engineering, and production needs.”