Meeting the demand for mass personalization at scale.

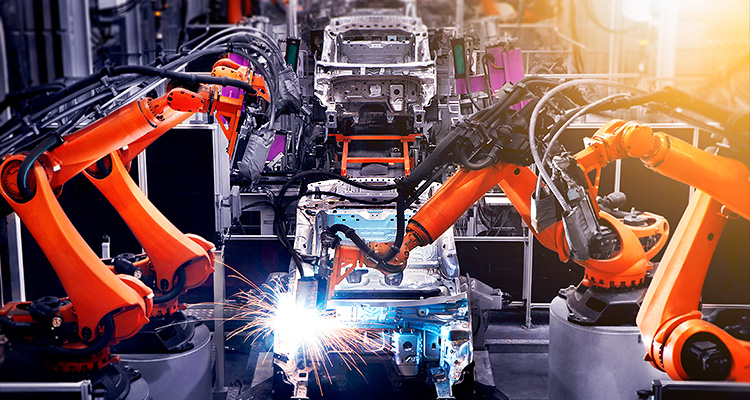

The traditional assembly line – with standardized parts, steps, and products – has long been the backbone of manufacturing for low-cost, high-volume goods. But as products grow more complex and consumer and regulatory expectations become more nuanced, a one-size-fits-all approach is no longer enough.

Consumers increasingly demand personalized products tailored to their specific preferences – from cars and smartphones to sneakers and appliances. Meeting this demand at scale, while maintaining profitability and managing cost, complexity, and supply chain constraints, remains a major challenge.

To adapt, manufacturers are turning to advanced technologies and strategies – such as product lifecycle management (PLM), the digital thread, and AI-driven manufacturing. Mass personalization is emerging as a critical focus, and understanding the drivers behind this shift – and the technologies that make it possible – can help manufacturers take practical steps toward large-scale custom production.

The evolving landscape of manufacturing customization

Historically, manufacturing prioritized high-volume, low-cost production of identical products. Every customer received the same item – same parts, same materials, same features. This approach was efficient, inexpensive, predictable, and required minimal skilled labor.

Today, this model no longer aligns with consumer expectations for tailored offerings – whether it’s custom-colored phones, personalized shoes, or uniquely configured vehicles. In response, manufacturers are updating their processes to serve these niche audiences with products that resonate personally, helping foster brand loyalty. This shift requires a more targeted approach to manufacturing known as mass personalization.

Customization in modern manufacturing can also be driven by regional regulations and material availability. For example, certain production materials may be restricted in Europe but permitted elsewhere. In such cases, manufacturers may tailor products regionally, using more expensive, compliant materials only where required.

Achieving mass personalization with modern technologies and processes

PLM as a foundation for personalization

Modern PLM platforms designed to support end-to-end product lifecycle visibility enable teams to work with structured, item-level data rather than static documents. This allows users to access and update relevant information in real time based on roles, permissions, and business context. This makes it easier to manage complex product configurations and personalize offerings at scale.

These solutions also support secure collaboration beyond organizational boundaries. With the right controls in place, manufacturers can share specific data and actively collaborate with external partners, such as suppliers or service providers, to reduce delays, align deliverables, and drive greater efficiency across the value chain.

Enabling continuity

with the digital thread

A digital thread connects a product’s data across the entire product lifecycle – from design and engineering to manufacturing, maintenance, and even product end-of-life. In the context of mass personalization, this continuous flow of information is crucial for managing complexity across multiple product variants and rapidly evolving customer demands.

By linking every stage of product development and delivery, the digital thread ensures that product data remains consistent, traceable, and up to date. This enables teams to identify dependencies and impacts of changes quickly, which is especially important when dealing with customized configurations.

For example, if a customer orders a product with a specific feature or material, the decision to create a new product variant and make it available for future customer requests flows through engineering, supply chain, production, and service without manual handoffs or data silos. The result is faster cycle times, fewer errors, and a more responsive manufacturing environment.

A robust digital thread also supports compliance and auditing by maintaining a full history of changes and decisions. This is essential for industries where traceability and regulation play a key role.

AI-driven manufacturing unleashed with connected intelligence

AI-driven manufacturing unleashed with connected intelligence

AI is unlocking new efficiencies across manufacturing, particularly when paired with accurate, well-structured data. With the right foundation in place, AI can surface insights that support faster decision-making, improve responsiveness, and reduce errors – especially in areas like quality, forecasting, and process optimization.

Some manufacturers are leveraging AI to deliver connected, role-based insights across systems, helping teams act on relevant information without switching between disconnected tools. This kind of access must be governed carefully, ensuring that sensitive product data is visible only to the appropriate stakeholders.

AI doesn’t create the digital thread – but it strengthens its value. When supported by clean, consistent, and traceable data, AI can help teams identify patterns, monitor changes across product configurations, and make informed decisions at scale.

Key mass personalization strategies for manufacturers

Successfully shifting to mass personalization requires more than product flexibility. It demands integrated planning, structured variability management, and digital continuity across the enterprise. Without the right strategies, technology, and governance in place, organizations risk higher costs, longer lead times, and missed reuse opportunities. Here are three foundational areas where manufacturers must focus to ensure success:

Modularization across products and processes

Modularization is critical for managing product complexity in a scalable way. By designing products as collections of standardized, self-contained modules or subassemblies, manufacturers can create flexible configurations without reengineering the entire product.

Each module can be independently designed, sourced, updated, and reused – allowing for faster customization while maintaining architectural integrity. In PLM, modularization also supports robust configuration management, traceable change tracking, and better collaboration across teams.

Strategic modularization enables organizations to deliver variety without compromising efficiency. Many seek out expert guidance to develop a modular mindset that extends beyond products to operating models and infrastructure.

Accurate demand forecasting for variant complexity

As personalization grows, so does the need for precise, dynamic demand forecasting. Manufacturers must estimate demand not just for core products, but across multiple configurations, regions, and customer segments – often while managing complex regulatory requirements.

Advanced statistical models help forecast demand across product variants and anticipate risks in sourcing and supply. Effective forecasting ensures that materials and components are available when needed, reducing excess inventory and avoiding stockouts that could disrupt the customer experience.

Advanced product

line management

As product lines expand to meet market demand, advanced product line management has become essential. Modular designs are just the beginning. PLM solutions must also support the rapid addition and retirement of product options, ensure consistency, and automatically validate configurations against established rules.

Manual checks are no longer viable when variant volumes scale. A flexible PLM platform must adapt to the organization’s evolving needs while maintaining governance over every change. To support this, product line management should be deeply integrated with the digital thread, ensuring traceability across variant definitions, business rules, and lifecycle activities. This traceability also lays the groundwork for advanced analytics and the eventual creation of digital twins.

Mass personalization is quickly becoming a competitive necessity – not just a customer preference. To succeed, manufacturers need flexible processes, reliable data, and the ability to manage complexity across product lines.

By adopting technologies like a modern PLM platform with robust digital thread capabilities and AI, manufacturers can make personalization scalable, secure, and efficient. The key is to build a digital foundation that supports real-time collaboration, traceability, and smart decision-making – without sacrificing control or increasing risk.

As market expectations continue to evolve, manufacturers that invest in connected, adaptive systems will be best positioned to deliver the tailored products customers want at the speed and scale to today’s landscape demands.

By Bruce Bookbinder

Bruce Bookbinder is a Product Manager at Aras. He is currently driving strategy for the Aras cloud and SaaS deployments as well as other technical aspects of the Aras PLM Platform. Before Aras, Bruce held several IT management and technology positions at General Electric, Avon Products, Reader’s Digest, and Control Data Corporation. Bruce holds an MS and a BS in Computer Science Management.

AI-driven manufacturing unleashed with connected intelligence

AI-driven manufacturing unleashed with connected intelligence