Mercedes F1 to Use Sustainable Carbon Fiber in 2025 Season

Subscribe to our free newsletter today to keep up-to-date with the latest manufacturing news.

Formula 1 has historically depended on carbon fiber composites to achieve lightweight strength and aerodynamic efficiency. But carbon fiber production is energy-intensive and difficult to recycle, raising sustainability concerns.

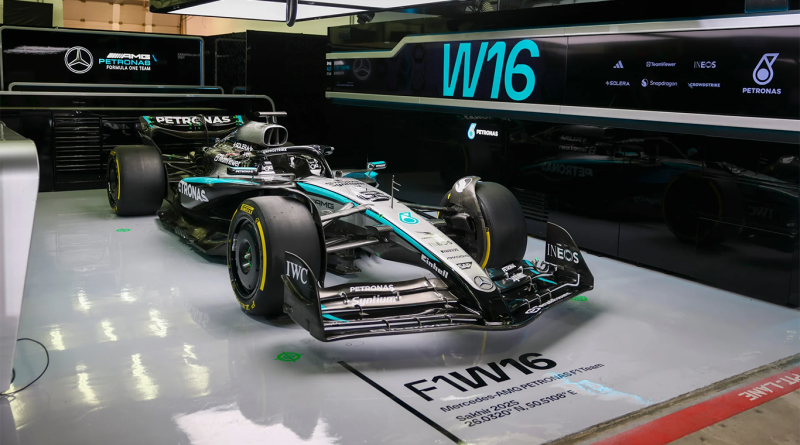

Recognizing this challenge, the Mercedes-AMG Petronas Formula One Team is taking a significant step toward sustainability. Starting with the 2025 Formula 1 season, the team will begin integrating sustainable carbon fiber composites into its race cars. This initiative aligns with its broader commitment to achieving Net Zero emissions by 2040, demonstrating that high-performance motorsport and environmental responsibility can coexist.

The role of carbon fiber in Formula 1

Carbon fiber composites are the backbone of modern Formula 1 cars, constituting approximately 75% of the car’s structural components. The material’s unmatched strength-to-weight ratio enhances aerodynamics, fuel efficiency, and crash safety. However, traditional carbon fiber production involves high energy consumption and significant carbon emissions, contributing to environmental degradation.

Beyond its manufacturing footprint, carbon fiber also presents challenges in end-of-life disposal. Unlike metals, which can be melted down and reused, carbon fiber composites are difficult to recycle efficiently. Many discarded F1 components end up as landfill waste or require energy-intensive recycling processes that are not yet widespread.

With sustainability becoming a core objective for teams and the FIA (Fédération Internationale de l’Automobile), the need for innovative solutions in material science is paramount. Mercedes-AMG Petronas F1’s initiative aims to revolutionize carbon fiber use in motorsport, reducing waste and emissions without compromising on-track performance.

Transition to sustainable carbon fiber composites

To address these sustainability concerns, Mercedes-AMG Petronas F1 is collaborating with leading material science and recycling experts to develop carbon fiber composites that reduce environmental impact. The focus is on using recycled fibers and bio-based resins, which offer comparable structural integrity while significantly lowering carbon emissions.

Two key objectives drive the team’s research and development efforts:

Increasing recyclability: New processing techniques aim to allow carbon fiber components to be reused or repurposed more efficiently. By developing a closed-loop recycling system, the team seeks to reduce reliance on virgin carbon fiber production.

Reducing production emissions: Alternative manufacturing processes, such as resin infusion with lower-temperature curing, can cut down energy consumption while maintaining performance standards.

The move towards sustainable carbon fiber requires overcoming technical challenges to ensure that performance, safety, and durability are not compromised. Traditional carbon fiber composites consist of roughly 60% fiber and 40% resin system by weight. Sustainable alternatives aim to replace conventional resins with bio-based options while optimizing fiber recovery from end-of-life components.

Innovations in material engineering are making it possible to extract high-quality fibers from retired parts, enabling their reuse in new components. Furthermore, advancements in bio-resins derived from renewable sources, such as plant-based polymers, are helping reduce reliance on petroleum-based materials.

Despite these developments, ensuring that sustainable carbon fiber meets F1’s stringent safety and performance standards remains a top priority. Every component undergoes extensive testing to validate its structural integrity and aerodynamic properties before being incorporated into race cars.

The advancements in sustainable carbon fiber are not limited to Formula 1; they have far-reaching implications for the broader automotive and aerospace industries. As manufacturers seek to reduce their carbon footprints, the innovations developed in motorsport could be adapted for mass production, improving the sustainability of consumer vehicles.

The team’s roadmap to Net Zero emissions by 2040 includes continued investment in greener technologies, from sustainable fuels to energy-efficient manufacturing processes. As teams and manufacturers embrace sustainability, motorsport will serve as a proving ground for materials and technologies that could define the future of transportation.

Sources: