Mikart’s reputation is built on trust, transparency, and a deep commitment to customer success

With five decades of experience, Mikart has firmly established itself as a reliable contract development and manufacturing organization, offering a comprehensive range of services. The company assists clients in scaling from early-stage concepts through to full commercialization. CEO Michael Kallelis, and Vice President of Marketing, Michelle Hall, share insights into Mikart’s journey, capabilities, and vision for the future.

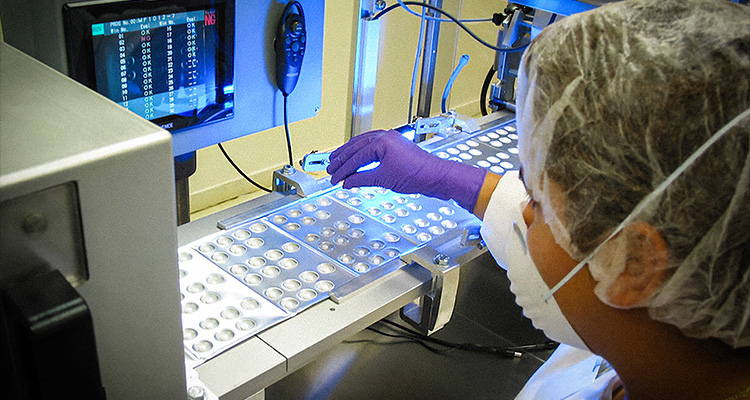

“Founded 50 years ago, Mikart is a mid-sized contract development and manufacturing organization (CDMO) based in the Southeastern US,” says Michael. “We specialize in the development and manufacturing of small molecule drugs, particularly oral solid doses, as well as non-sterile liquids and suspensions.”

As a full-service CDMO, Mikart supports every stage of the pharmaceutical product lifecycle. “We offer end-to-end services, from early-phase clinical trial materials to full-scale commercial production,” he explains. “Our Pharmaceutical Development Services (PDS) team handles everything from formulation chemistry and analytical method development to sourcing raw materials. Once a product receives FDA approval, we seamlessly transition into commercial manufacturing, supporting batch sizes from niche orphan drugs to high-volume generics.”

To broaden its capabilities, Mikart recently invested in a state-of-the-art liquids suite, expanding its ability to manufacture complex suspensions. “Suspensions are not simple to formulate or package,” Michael notes. “We’ve made significant investments in both the technology and expertise required to do it right. Adjacent to this, we have a full-scale packaging facility that supports most of the products we manufacture.”

While some companies specialize solely in packaging, Mikart includes it as part of its integrated offering. “Over 90 percent of our packaging is for products we manufacture,” Michael adds. “Our customers benefit from a single point of contact—they don’t need to work with multiple vendors for development, testing, manufacturing, and packaging. We provide a fully turnkey solution.”

One of Mikart’s defining traits is its longevity and stability. “Celebrating 50 years is a milestone we’re incredibly proud of,” says Michael. “When customers choose us, they’re partnering with a company that’s not only well-established and well-funded, but also built to last.”

Michael also highlights the strength of Mikart’s formulation chemistry division. “We’re staffed with top-tier talent – respected professionals known throughout the industry. That depth of experience builds trust. Clients know they’re working with a capable, reliable team, not a low-cost provider making promises they can’t keep.”

Trust and follow-through are at the heart of Mikart’s success. “We’re known for doing what we say we’ll do. That credibility matters,” Michael emphasizes. “Clients appreciate our transparency, especially when issues arise. We’re honest, solutions-oriented, and focused on delivering on time and within budget.”

Trust and follow-through are at the heart of Mikart’s success. “We’re known for doing what we say we’ll do. That credibility matters,” Michael emphasizes. “Clients appreciate our transparency, especially when issues arise. We’re honest, solutions-oriented, and focused on delivering on time and within budget.”

Flexibility is a cornerstone of Mikart’s approach. “We customize our business terms to align with each client’s unique circumstances,” Michelle explains. “A startup with limited cash flow has very different needs than a global pharmaceutical company. Others may need to move quickly to be first to file. Our agility, alongside our credibility and collaborative approach, sets us apart.”

This adaptability is part of Mikart’s commitment to providing tailored solutions that meet the diverse needs of its clients. By understanding the specific challenges and goals of each partner, Mikart ensures a collaborative and responsive partnership throughout the drug development process.

Looking ahead, Mikart is focused on operational excellence, particularly in light of global economic pressures. “There’s increasing uncertainty around tariffs and the cost of raw materials like APIs and excipients, which are often locked in due to validation requirements,” Michelle says. “Since we can’t always control material costs, we’re improving internal efficiency to reduce labor hours per batch.”

By embracing lean practices and continuous improvement, Mikart aims to offset rising input costs while maintaining competitive pricing for customers. “If prices go up, we’re ready,” Michelle concludes. “If they don’t, we’ll be even better positioned to support our clients in a challenging marketplace.” ■