New technologies

Meeting in Nairobi in December 2017, the United Nations Environment Assembly claimed, unless we take action, our oceans will contain more plastic than fish by 2050. That one fact alone sent shockwaves around the world.

The problem is, plastic is one of the most versatile materials for industry and consumers, yet the most damaging for the environment.

While there remains a degree of skepticism about the detail, nature and geographical source of global plastic waste, there is clearly no time to be lost in addressing the bigger issue. There are aspects to the plastics crisis within our control and opportunities to demonstrate our commitment cooperatively across the world.

Bioplastic is one innovation helping to reduce the environmental impact, alongside other

Bioplastic is one innovation helping to reduce the environmental impact, alongside other

Let’s explore each material technology in more detail…

What are recycled plastics?

Recycling plastic is one of the oldest and most widely adopted ways of reducing plastic waste. It involves repurposing scrap or waste plastic items by melting them down into their raw components to create ‘new’ recycled plastic.

Broadly, there are two ways plastic can be recycled: mechanical recycling, whereby plastic is washed, ground into powder and melted, and chemical recycling where chemicals break down plastics into its basic components to be remolded.

While this has been the status quo for years, it’s a fundamentally flawed approach for the long term.

That’s because it’s difficult for recovery facilities to make money from low-value plastic items, different plastics when melted phase-separate like oil and water causing structural weaknesses and limitations on future applications, and in the recycling process new plastic materials have to be added in order to improve the integrity of the material. This can only be done two or three times before the plastic is unusable.

In addition, many resin types aren’t yet widely recycled, leaving consumers confused.

What are bioplastics?

Bioplastics are built on the premise that to make a more sustainable plastic, its chemical components must be more sustainable.

Plastic, as we know it, is a carbon-based polymer made mostly from petroleum, a non-renewable fossil fuel. This makes its safe disposal difficult because the burning process gives off toxic chemicals such as dioxins. Recycling all the different forms of plastic is also too much of a challenge for most local authorities, given the multitude of processes needed to recycle each individual type of resin.

In a bid to overcome these challenges and reduce the amount of plastic waste in landfill, a range of bioplastics have been developed. These are made from a host of natural materials and have two environmental advantages: they absorb as much (if not more) CO2 before being converted into plastic as they release when they break down, and when they’re disposed of they are generally compostable, meaning they do not harm the natural environment.

Bioplastics are currently being used or developed from raw materials such as sugarcane, corn, soy, agave, woodchips, and food waste (polylactic acids – PLA).

PLA is the cheapest and most widely used bioplastic today. Then there’s PHA (polyhydroxyalkanoates) made from microorganisms which is increasingly being used in medical devices. Other types of bioplastics are cellulose-based plastics, starch blends and lignin-based polymer composites.

However, not all bioplastics are biodegradable, which undermines their comeffectiveness in the fight against plastic waste. Although, it’s important to stress it’s definitely a step in the right direction.

What are biodegradable plastics?

Biodegradable plastics help to overcome the challenge of what to do with plastic when it’s disposed of.

While bioplastics are made up of biological-based polymers, a plastic is only considered biodegradable if it degrades in water, carbon dioxide, or biomass.

Bio-based PLA, for example, is compostable but only under strict environmental conditions such as high temperatures, UV light, pressure and nutrient concentration, and specific chemical ratios.

In addition, there are oxo-degradable plastics which are simply conventional plastics with additives called prodegredants that accelerate the oxidation process.

What can we expect from bioplastics in the future?

In recent years, there has been a big shift towards bioplastics by large multinational corporations and small eco-brands alike. Consumers are also growing more aware of new plastic technologies and their benefits.

So much so, the bioplastics market is expected to reach over $68.5 million by 2024.

But while this sounds like a lot, it actually still only represents a very small slice of the overall plastics market.

What’s holding the mass adoption of bioplastic back is how these bio-based materials perform in comparison to cheaper traditional plastic which can sometimes compromise packaging and the product inside. And, of course, the biodegradable problem.

Packaging and product manufacturers are working hard to overcome these challenges, developing formulas which allow any type of plastic to degrade naturally and faster in both aerobic and anaerobic environments without the need for UV or high temperatures.

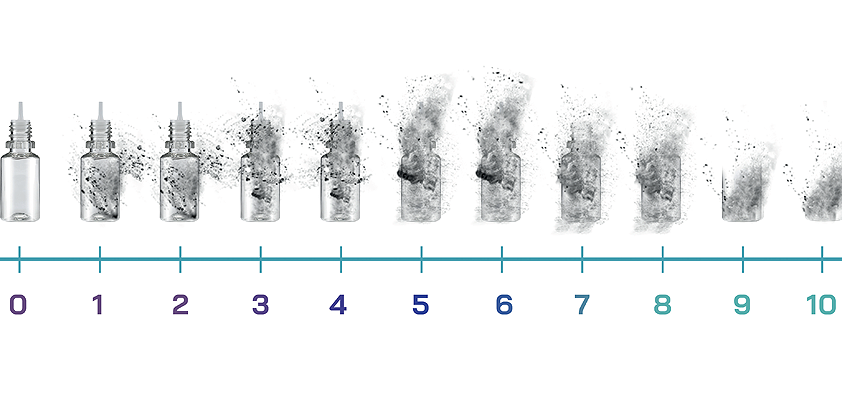

For example, BioPAC which is a unique plastic additive added into the base polymer – such as PP, PE, PS, PET, and other major resin types – and enhances its biodegradability. Specifically, the formula allows acids, secreted naturally by over 600 microbes, to soften the macromolecules within the plastic.

Other new techniques being explored include programming microbes to degrade plastics using synbio techniques and developing the relevant enzymes for degradation through protein engineering.

There are also positive strides being made in reducing the amount of land needed to grow raw materials, which form the basis of bioplastics; land which is needed for crop cultivation to feed people and animals. Scientists have recently developed a sustainable plastic that doesn’t need land or water for production, created from microorganisms that feed on seaweed.

So, while there are currently limitations to just how ‘eco-friendly’ bioplastics are, every year we’re seeing new technologists hit the mass market which help solve some of the fundamental problems of biodegradability and resources needed for their production.

And with this scalability, the price of bioplastic will fall dramatically. Coupled with growing consumer awareness for sustainable products and practices, this in turn will help drive the market towards the mass adoption of bioplastics.

Rich Quelch

Rich Quelch is Global Head of Marketing at Lifestyle Packaging. Lifestyle Packaging designs, customizes and supplies packaging to a range of industries – including CBD, fragrance, skincare and aromatherapy – and is a market leader in child-resistant packaging. Lifestyle Packaging also specialises in supply chain management, with a unique model to reduce costs and increase speed to market.

www.lifestylepackaging.com/biodegradable-plastic-packaging