North American Steel’s expansion is driven by cutting-edge automation and robotic manufacturing advancements

North American Steel is a Canadian manufacturer and service provider of pallet racking and industrial storage systems. It manufactures one of the widest varieties of racking products in the North American market and also provides in-house design, engineering, and project management services. The company boasts the ability to handle everything from concept to completion. Mike Tripp, VP of Operations, sheds more light on the company’s story: “We have a long and established history. The business was first incorporated in 1952 as a subsidiary of Steel Equipment of England, which was originally founded in 1898. In 1972, North American Steel was acquired by the Fabricius family, who continue to own and lead the company to this day.

“Our President, Rolf Fabricius, is well-known in the racking industry. He has played a key role in developing Canadian safety standards for racking systems and holds several patents for unique racking products and engineering designs. His leadership and commitment to product safety and innovation have shaped our company culture and reputation.

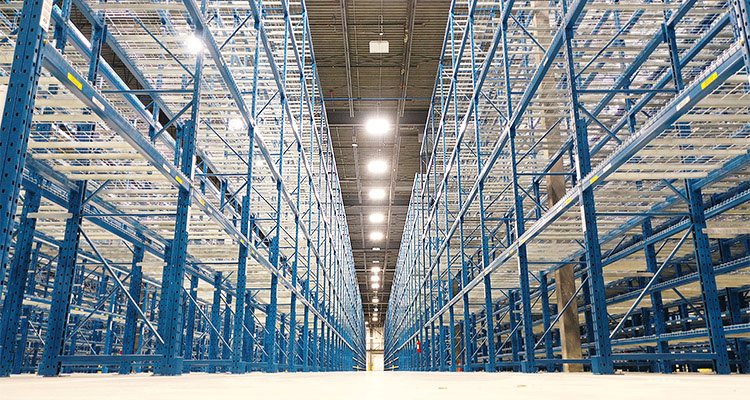

“We offer one of the most extensive and flexible ranges of racking systems in the industry. Our manufacturing capabilities allow us to produce both roll-formed and structural steel racking systems, which gives our team the flexibility to deliver fully customized solutions based on specific project needs.”

Mike goes on to emphasize how the industry has evolved. “Racking systems today are far more than steel frames for storing pallets,” he says. “They are critical pieces of infrastructure that support safety, workflow efficiency, and operational success. When designed and built correctly, they serve as the backbone of a warehouse or distribution center.”

Given the essential role that the right racking systems play in the productivity of an operation, the quality of the products is pivotal. North American Steel offers end-to-end services to ensure that it can meet the needs of even the most demanding client. “On the service side, we provide everything from structural engineering and layout design to permitting, budgeting, quoting, project management, installation, and inspections,” Mike confirms. “We strongly believe in keeping as many services as possible in-house. That includes engineering, manufacturing, and project coordination. It allows us to maintain quality control, be more responsive to clients, and ensure every project meets our high standards from start to finish.”

The company has recently dedicated substantial resources to advancing automation within its facilities. Mike outlines the strategy and its benefits: “This has been a key priority for us over the past few years. We have made substantial investments across four of our core facilities in Whitby, Colborne, Mississauga, and Nisku. These upgrades have completely transformed the way we manufacture and manage production workflows.

“Our automation initiatives include the implementation of high-speed roll-forming lines equipped with automated coil feeding, robotic welding stations that deliver consistent and high-quality joints, CNC-controlled punching systems, and smart material handling equipment that has increased throughput while reducing manual labor. These systems are all integrated with our ERP (enterprise resource planning) software to provide real-time production tracking and greater visibility across the shop floor.

“One of the most exciting developments is our investment in fully robotic manufacturing cells, which automate the entire process from raw material feeding through to fabrication without human intervention. We are also in the process of installing a fully automated paint line and packaging system. Once operational, this will allow products to move from raw steel to finished, painted, and packaged components without being touched by a single hand. To our knowledge, this will be the first complete end-to-end automated racking line of its kind in Canada.

“The benefits so far have been very clear. We have seen a major increase in production capacity, significant improvements in lead times, and much greater consistency in product quality. Automation has also enhanced workplace safety by minimizing manual handling in high-risk stages of production. These investments have made us more accurate, efficient, and most importantly, they’ve positioned us to take on larger and more complex projects without compromising on quality or delivery timelines.”

This approach helps the business deliver substantial and challenging projects to the highest standard. Mike provides an example of a complex project which was completed recently: “One was a large-scale project for a major Canadian grocery chain that required a cold storage racking solution in a high seismic zone. Our engineering team developed a hybrid system that used structural racking throughout the refrigerated and high-impact areas, while utilizing roll-formed racking in the ambient zones. This approach provided the strength and compliance required for seismic conditions, while also controlling overall project costs.”

Turning to the topic of changes brought on by the current political landscape, Mike discusses the challenges and advantages presented by the Trump administration’s tariffs. “With respect to tariffs, we see two sides of the situation, both of which have impacted us in different ways. On the negative side, the uncertainty around tariffs and trade policy has created hesitation in the market. Even if a client is not directly impacted by a tariff, the general economic anxiety it creates has led to increased caution and delays in procurement decisions. We’ve seen this affect timelines and planning cycles across several industries, and it’s something we monitor closely. On the plus side, being a fully Canadian manufacturer that sources raw materials from domestic suppliers, we’ve largely avoided direct cost impacts associated with international tariffs. In fact, this has started working in our favor in certain situations. For example, several American companies with operations in Canada previously standardized their racking procurement by sourcing all their product from US suppliers and shipping across the border to maintain uniformity between locations. With ongoing tariff uncertainty and rising transportation costs, many of these companies are now reassessing their procurement strategy.

Turning to the topic of changes brought on by the current political landscape, Mike discusses the challenges and advantages presented by the Trump administration’s tariffs. “With respect to tariffs, we see two sides of the situation, both of which have impacted us in different ways. On the negative side, the uncertainty around tariffs and trade policy has created hesitation in the market. Even if a client is not directly impacted by a tariff, the general economic anxiety it creates has led to increased caution and delays in procurement decisions. We’ve seen this affect timelines and planning cycles across several industries, and it’s something we monitor closely. On the plus side, being a fully Canadian manufacturer that sources raw materials from domestic suppliers, we’ve largely avoided direct cost impacts associated with international tariffs. In fact, this has started working in our favor in certain situations. For example, several American companies with operations in Canada previously standardized their racking procurement by sourcing all their product from US suppliers and shipping across the border to maintain uniformity between locations. With ongoing tariff uncertainty and rising transportation costs, many of these companies are now reassessing their procurement strategy.

“What has helped us tremendously is the fact that we manufacture both ‘American style’ and ‘Canadian style’ racking systems domestically in Canada. This allows US-based companies with Canadian operations to achieve the consistency they want across locations, while mitigating the risk and expense of importing racking into Canada. As a result, we’ve seen a noticeable increase in inquiries from US parent companies looking to secure local Canadian suppliers for their Canadian warehouses and distribution centers,” he enlightens.

Mike then concludes by outlining the company’s vision for the future: “This year is shaping up to be one of significant momentum and strategic growth for North American Steel. We are seeing increased activity in nearly all sectors. The projects we are delivering now are larger, more complex, and involve more detailed coordination than ever before.

“Internally, we are also growing rapidly. We are expanding our sales, engineering, and operations teams to make sure we continue delivering the responsiveness and hands-on service our customers expect. At the same time, we are investing in new software tools, upgrading our ERP integrations, and training programs to improve efficiency and support team development.

“In parallel with our operations, we are also working on new product innovations. These innovations will add even more flexibility and performance to our modular systems and help our clients take advantage of new trends in automation and high-density storage. We are building the systems, processes, and team capabilities that will carry us through the years and beyond.

“In the next five years, we envision North American Steel as the most trusted and recognizable name in engineered racking systems across the continent. Our goal is to be the first call any company makes when they are looking for a partner who not only manufactures racking but understands the full lifecycle of storage systems, from planning and compliance to installation and ongoing support.”

https://naseco.ca