Pamarco’s laser-engraved anilox rolls meter ink with unparalleled precision for high-speed printing solutions

With nearly 80 years of proven success and innovation, Pamarco is a trusted global leader in anilox technology, dedicated to being the preferred supplier of world-class, sustainable anilox products and services for the packaging and print industries. From precision-engineered anilox rolls to advanced blades and accessories, the company is committed to enabling high-quality, high-speed, and high-volume printing without compromise. Pamarco’s personalized support and industry-leading service ensure that clients achieve optimal performance and efficiency in their operations. John Burgess, President, joins us for an informative discussion on the business’ history, capabilities and operations.

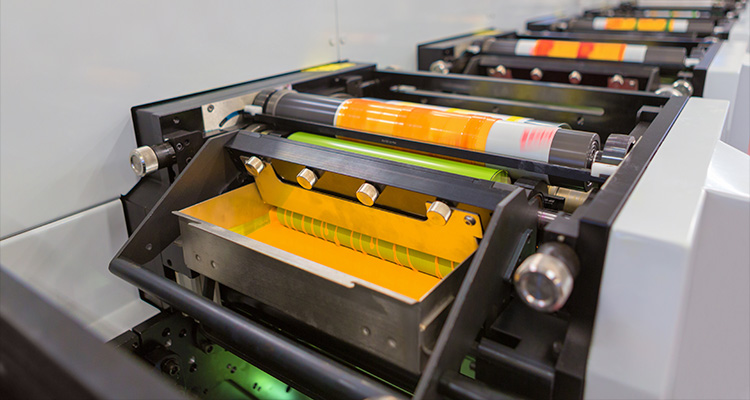

“Pamarco was founded in the 1950s by two entrepreneurs in the US to service a new technological area in printing known as aniline printing, named for the ammonia-based inks used at the time. To meet the needs of this market, Pamarco developed the anilox roll, a crucial component in flexo printing that transfers ink from a source, such as an ink pan or pump, to a printing plate. Unlike traditional methods that flood the plate with ink, the anilox roll uses tiny precision-engineered holes to meter a specific amount of ink. For example, when printing on a corrugated box, a larger amount of ink is needed due to the material’s absorbency, while printing a barcode on a crisp bag requires only a small amount. Initially based in New Jersey, the business quickly recognized the need for localization, leading to expansions into Atlanta, Chicago, and later California. In 1994, Pamarco was sold to equity investors, and since then, it has operated under three different equity owners, with the current owner having maintained the business for 19 years. During this time, we have expanded our facilities in Atlanta, California and Chicago, and in 1996, we acquired a plant in the UK. However, we recently closed that facility and instead purchased a new factory in Germany, thus establishing a presence in mainland Europe,” he begins.

“Pamarco was founded in the 1950s by two entrepreneurs in the US to service a new technological area in printing known as aniline printing, named for the ammonia-based inks used at the time. To meet the needs of this market, Pamarco developed the anilox roll, a crucial component in flexo printing that transfers ink from a source, such as an ink pan or pump, to a printing plate. Unlike traditional methods that flood the plate with ink, the anilox roll uses tiny precision-engineered holes to meter a specific amount of ink. For example, when printing on a corrugated box, a larger amount of ink is needed due to the material’s absorbency, while printing a barcode on a crisp bag requires only a small amount. Initially based in New Jersey, the business quickly recognized the need for localization, leading to expansions into Atlanta, Chicago, and later California. In 1994, Pamarco was sold to equity investors, and since then, it has operated under three different equity owners, with the current owner having maintained the business for 19 years. During this time, we have expanded our facilities in Atlanta, California and Chicago, and in 1996, we acquired a plant in the UK. However, we recently closed that facility and instead purchased a new factory in Germany, thus establishing a presence in mainland Europe,” he begins.

Building on its rich history and strategic expansions, Pamarco is prepared to meet the changing needs of its customers with enhanced offerings. “Many of our customers are investing in new equipment and presses, so we supply them with brand-new rolls and sleeves for their printing presses. Additionally, we offer refurbishment services for existing equipment, which is why we have established a regional presence in key areas of the flexo industry. Indeed, we strategically operate in hotspots such as the Midwest, the Deep South and the West Coast. The corrugated box market has experienced significant expansion over the past five years, particularly since the pandemic, due to the surge in e-commerce and the reliance on corrugated packaging for deliveries. Meanwhile, plastic packaging is somewhat under attack over its lack of recyclability and sustainability, prompting our customers to look for more eco-friendly alternatives,” John informs.

Delving deeper into the topic of sustainability, John highlights its influence on the printing marketplace. “As our offerings are focused solely on print characteristics, we do not directly provide products that enhance sustainability. However, our customers are making strides by changing the basis weight of their papers and opting for lighter materials. By prioritizing lighter materials, they can reduce fuel consumption during transportation. Additionally, many of our customers are now using very little virgin pulp, preferring to incorporate as much recycled material as possible instead. On average, a corrugated box can be recycled up to seven times, which is a significant benefit for the market. The fiber used in paper shortens with each recycling cycle, and it is generally accepted that after seven rounds of recycling, the fiber becomes too short to be reused and becomes a waste product. Despite this limitation, corrugated materials remain a highly sustainable option.”

To enhance efficiency, Pamarco has invested in various technologies, such as advanced laser engraving machines. We learn more about the nature and purpose of these investments from John. “Laser engraving equipment is comparable to the evolution from a Disk Operating System (DOS) computer to a modern Microsoft Surface, with all the generations in between. When you purchase a laser today, it will not become obsolete in two years, but the technology does move on greatly. Therefore, we need to constantly keep pace with the latest technological innovations. The newer machines offer several advantages, including reduced maintenance and increased speed. For instance, what used to take us 24 hours to engrave can now be done in just six-to-eight hours with the latest machines. Moreover, these advancements allow us to enter new markets, which is a key focus for us with the recent equipment we have acquired.

“Beyond that, one of the key technological areas in our manufacturing process is what we refer to as plasma spray. Every one of our products is coated with a material called chromium oxide, which needs to be sprayed using a high-tech gun that operates at high speeds and temperatures. The efficiency of this gun is crucial to guarantee both the effectiveness and quality of the spray. In the past, we would spray ten pounds of material, but only about two pounds would adhere to the roll. This measure is known as deposit efficiency. Today, we have improved this process significantly. Now, when we spray ten pounds, approximately 6.5 pounds stick to the roll. This substantial increase in deposit efficiency is a direct result of our investments in new equipment. Ultimately, these advancements contribute to faster manufacturing and a reduction in waste,” John concludes.

Pamarco’s legacy as a global leader in anilox technology is grounded in a strong commitment to innovation, sustainability, and consistent quality. With nearly 80 years of experience in pioneering print solutions, the company consistently redefines industry standards, enabling clients to achieve superior efficiency and performance.