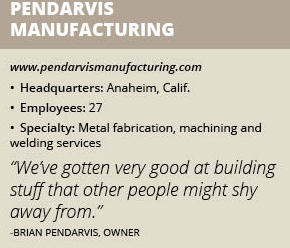

Pendarvis Manufacturing

Pendarvis Manufacturing is not a company that walks away from a challenge. Over the past 36 years, “We’ve gotten very good at building stuff that other people might shy away from,” owner Brian Pendarvis says.

Based in Anaheim, Calif., the company offers metal fabrication, machining and welding services to clients in its home city, as well as Los Angeles and the surrounding Southern California areas. Pendarvis’ father, Robert “Bud” Pendarvis, started his namesake company in 1982, after gaining more than 20 years of manufacturing experience.

At the time, the elder Pendarvis was serving as the general manager of a welding, fabricating and machining shop, but the time was right to start his own venture. “The manufacturing base in Southern California is big,” Brian Pendarvis says.

His father then left his job to start the company, which began with only a single knee mill, a manual lathe, a small radial arm drill and two weld stations. The eldest son Douglas, who was a machinist by trade, was part of the company from the beginning.

“Our emphasis over the years has been machining and welding under the same roof,” Brian Pendarvis says, noting that he joined his father and brother at Pendarvis Manufacturing full-time in the spring of 1985.

Problem Solvers

Today, Brian Pendarvis is the owner of the company, which employs a staff of 27 and operates from a facility in Anaheim that features more than 15,000 square feet of manufacturing space. “We are the epitome of what we call ‘a job shop,’” he says.

Pendarvis Manufacturing has thrived in its market, he notes, by being responsive to its clients and providing quality products. In addition, “We solve various manufacturing problems. One great example is from early this year,” Pendarvis states.

“About two weeks before the opening game at Angels Stadium in Anaheim earlier this spring, I received a call from the contractor that was installing the new scoreboards and speakers in the park,” he recalls. “They were just about done with the project and needed some custom-built speaker mounts to mount new speakers around the new LED Screens in the outfield.

“They gave me some conceptual drawings,” he continues. “I reviewed the field conditions and our team came up with a simple solution. There were a total of five different frames. Five days later, they were installing the first frames. All of this was done in less than two weeks after the initial call.”

Pendarvis adds, “I circled back a couple of weeks later to see how the install went and the fella in charge told me that our team did an excellent job with zero hiccups to deal with. I’d call that a home run!”

Although the firm has completed work in the transportation, aerospace, defense, oceanographic and industrial wastewater sectors, it does not limit itself to a specific niche. “I tell people, ‘If we can cut it, weld it, machine it, paint it, put it on a truck and make a dollar, we’ll do it,” he says.

“We are process driven – regardless of the industry we work in,” he continues. “We know where our sweet spot is and excel within our sweet spot.”

Pendarvis Manufacturing’s focus on quality also has earned it the business of prominent amusement parks in Southern California. “In 2017, we had projects in three of the major Southern California parks,” Pendarvis states. “They hire us to handle some very complex projects.”

Keeping Busy

It is a good time for Pendarvis Manufacturing to be in business. “The current economic climate is pretty good,” Brian Pendarvis says, adding that Southern California is the largest concentrated area of manufacturing in the country. “We’ve got a lot going on.

“The diversity of skill sets within our team is reflected in the different projects we can tackle,” he adds. “Our team brings a lot to the table.”

A key factor in the continued activity at Pendarvis Manufacturing has been the company’s marketing campaign. The primary tool in its marketing arsenal is their website. “A thorough, Internet-based marketing program has brought us a lot of opportunities in the last 15 years,” he says, noting that this has made Pendarvis Manufacturing’s phone ring with new opportunities, “pretty much every day.”

Pendarvis adds, “Since January of this year alone, we have landed three large fabrication projects. Some stainless steel, some carbon steel and some aluminum. A good amount of precision machining and a lot of welding and fabrication.

“All of these projects” he affirms, “fit right in our sweet spot.”

When asked to go dig deeper about the importance of a good website, “A strong web presence that tells the story of a company is vital in today’s marketplace,” Pendarvis shares. “A lot of study and intention took place to get our current website launched.

“All of the current Internet marketing tools are used to attract potential clients that are a good fit for us. One of the biggest objectives of our website is for the person that found us to say to themselves, ‘These Pendarvis folks have the competence to make what we need made,’” he says. “And from the feedback we receive, our marketing team has done just that.”

But the company’s work can bring its share of difficulties, Pendarvis admits. “In the fast paced environment we live in, one of the biggest challenges is lead times. It seems that each year our customers are seeking shorter lead times,” he says, noting that the company also has to be careful not to spread itself too thin. “We navigate this issue the best we can.”

Looking Good

Pendarvis Manufacturing focuses heavily on workmanship. Pendarvis notes that he manages the company with the sharp focus on quality. “To me, the look and feel of a finished part is just as important to me as the dimensions on the drawing,” he says. “To that end, we get a lot of compliments on our workmanship!”

Pendarvis Manufacturing focuses heavily on workmanship. Pendarvis notes that he manages the company with the sharp focus on quality. “To me, the look and feel of a finished part is just as important to me as the dimensions on the drawing,” he says. “To that end, we get a lot of compliments on our workmanship!”

The company focuses on efficiency, which has led it to use lean manufacturing approaches on a daily basis. “Part of my task as the owner is to coach our leaders through the manufacturing process and say, ‘Let’s not pick this up five times, let’s pick it up one time,’” he says. “Some call it ‘lean,’ but it’s really about efficiency in a process.”

Pendarvis Manufacturing’s focus on efficiency also drove it to invest in E2 Shoptech, its ERP system. “That was a big investment,” Pendarvis says, noting that the company implemented the software in early 2017.

Since then, the company has enjoyed improvements in managing and scheduling projects. E2 Shoptech has a lot of great features. The most important ones for the company are the ways it now manages due dates, purchasing of raw materials and costing of projects.

This has eliminated Pendarvis Manufacturing’s previous system, where a single lead person kept track of all of the company’s projects. Today, “Our teams have their lists of projects and they can plan better, based on due dates,” he says.

Valued Relationships

A valued part of the culture at Pendarvis Manufacturing has been the focus on its team. “I was part of the Care Ministry team at the church I belong to,” Pendarvis shares. “One thing I have learned through the years is that life happens.

“People come to work and sometimes life is just kicking their butts,” he says. “Divorce, family issues, deaths in the family. Life. In an effort to support our guys and gals we have partnered with an organization called Marketplace Chaplains.”

He adds, “The team from Marketplace Chaplains makes regular visits in our shop. They visit with our people and offer their services as needed. This has been a much-valued resource we offer our team members.”

This also has help nurture longevity in its staff. “Over 45 percent of our people have been here over five years,” he says, noting that its longtime employees include CNC Machine Shop Manager Charlie Rice, Office Manager Alma Munoz and Rich Strever, a member of its engineering team. “Good people and invaluable members of our organization. Let me add ‘friends’ to that list too!”

The company also strongly values its relationships with its suppliers. “My father taught me years ago to look at our suppliers as partners, from our material suppliers to our paint vendors to the heat-treating shops we use,” Pendarvis says. “They’re a vital component to our success.”

Pendarvis sees a strong future for the company, but one that will be focused on efficiency. “It’s not all about the sales dollars and volume,” he says. “What it’s about is the efficient way we manage a project. In a nutshell, I want to do the same with less.

“My primary goal with implementing E2/Shop Tech was to squeeze out efficiencies in our shop. Better planning = Efficiencies. The age-old mantra of ‘Plan the work – Work the plan.’ Yup, that’s our goal.”

A Strong Resource

Brian Pendarvis is a member of the Los Angeles Chapter of the National Tooling and Machining Association (LA/NTMA), which strives to be a center of knowledge for the precision manufacturing community. “We offer networking opportunities, management ideas, technology updates and other exclusive membership benefits,” The LA/NTMA Website says.

Pendarvis has personally enjoyed these benefits as he and other members will get together and talk about the industry and what affects our multiple times a year. Recently, “I attended a business workshop on cybersecurity,” he recalls. “Where else is a small shop like ours going to get information like that?”

The NTMA website notes that it has a rich history. “Our members are part of an indispensable, $40 billion industry,” it says. “We foster the growth of creative and talented manufacturing professionals; we support each other in excellence and innovation and we help train those new to the field.”

Although the majority of precision tooling and machine shops are small, they flourish in every state, the association says. “Manufacturing creates three to five times more secondary employment than service industries,” it says.

“Our skilled jobs command above average salaries, offer family benefits, contribute to our nation’s economic stability and produce tax revenues for our communities, our states and our nation,” LA/NTMA says. “Over 75 percent of U.S. exports are manufactured goods that foster economic growth in such vital industries as defense, aerospace, automotive, energy, appliance, electronics, medical and construction.”

Sidebar — Fabrication Experts

Pendarvis Manufacturing says its location in Southern California puts it in an ideal place to manage its clients’ stainless-steel fabrication and machining needs. “With modern in-house CNC machining capabilities, six welding stations and hundreds of combined years of experience taking designs and creating custom precision parts and massive engineered structures, Pendarvis is able to cut, weld, machine, assemble and finish any stainless-steel fabrication project to precise standards for a wide variety of industries,” it says.

The company notes that stainless steel is well suited for fabrications that need great mechanical strength, high-corrosion resistance and low maintenance. “As one of the most comprehensive manufacturing firms of its kind, Pendarvis Manufacturing brings value-added experience and resources to projects as small as your hand and as large as can fit on the back of a big-rig trailer,” it says.

Pendarvis Manufacturing also excels at specialty cargo container fabrication. “Since 2011, we have teamed up with various units in the military to solve some unique storage challenges.

“Through precision engineering and craftsmanship, we have designed a rugged, durable and cost-effective storage system geared towards today’s warfighter’s requirements,” it says. “This American-made product considers all the flexibility needed or multiple shipping or storage needs.”

Sidebar — Offering the Best

Pendarvis Manufacturing says it provides clients with unmatched knowledge when it comes to precision machining. For example, “To provide CNC machined parts with precision and tight tolerances that many industries require, we offer the machining experience from our staff and some of the best in CNC machines and technology,” it says.

“With over 100 combined years of machining experience, we offer precision CNC machining services for a variety of metals and shapes,” the company continues, adding that its Hurco mills enable Pendarvis Manufacturing to machine parts in an extremely efficient manner to each of our customer’s requirements.”

The company also offers innovative welding services, including its welding of stainless steel. “We are capable of welding a variety of shapes, such as channels, bar, sheet, angles, plate and tubing,” it says. “As an experienced weld shop in California, we can perform stainless steel welding on components, parts and assemblies as small as what would fit in the palm of your hand to as large as 10 tons. Pendarvis Manufacturing offers welding to various AWS specifications and also holds a LA Fabricators Certificate for Structural Steel.

“Stainless steel grades, such as 304L and 316L, are easy to weld and exhibit very good strength, making them excellent candidates for many stainless-steel welding applications,” it says. “17-4 stainless has been used in projects that require special heat-treating after the welding has been completed.”