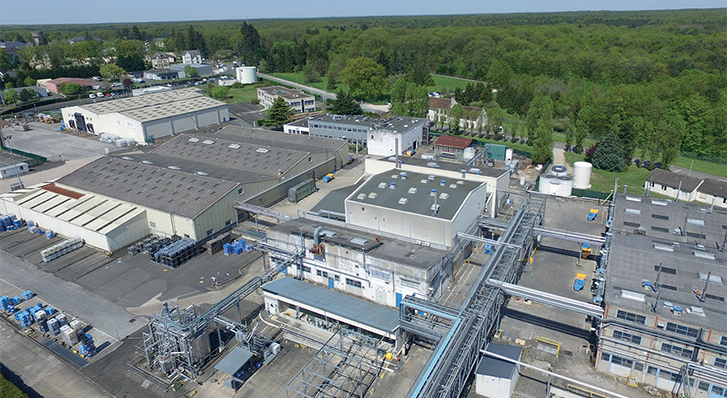

Pioneering plant

Old mattresses made of polyurethane foam will now be recovered, dismantled and chemically recycled to create a new polyol, which is a key starting material to produce polyurethane. This RENUVATM polyol is designed for various applications including mattresses. The unveiling is a major step forward for the recovery and recycling of polyurethane foam and a significant advance for closing the loop for end-of-life mattresses. At full capacity the plant will process up to 200,000 mattresses per year to tackle the growing mattress waste problem.

“We are immensely proud to have unveiled this plant. By doing so we are answering the question of what can be done with recycled polyurethane foam. It is part of Dow’s strong commitment to delivering solutions that help close the loop and protect our environment,” commented Marie Buy, Sustainability Leader EMEAI, Dow Polyurethanes, “As RENUVA™ now shifts focus to the production phase and the first foam made with the new polyol, our Dow Polyurethane sustainability journey continues. We are actively exploring future possibilities for recycled material and potential applications. It is really a new beginning.”