Power meets protection with specialist electrical enclosure manufacturer, Saginaw Control & Engineering

Specializing in standard stock and custom electrical enclosures, family-owned manufacturer, Saginaw Control & Engineering (SCE), represents the finest in quality US manufacturing. Forged from humble roots, the business was originally established in a garage but, with decades of hard work, passion and expertise, has since grown into a leading partner within the electrical industry. The company currently boasts seven locations across six states, with two state-of-the-art production facilities in Michigan.

Utilizing specialty equipment, cutting-edge technology and innovative manufacturing processes, SCE offers its customers a vast scope of custom capabilities and metal services, including high-tech welding and fiber-optic laser cutting. This provides a truly custom-made experience centered around the highest standards of customer care, whilst its extensive portfolio presents a wide selection of standard stock enclosures and customized enclosure solutions – including NEMA Types 1, 3, 3R, 4, 4X and 12 – suited to a multitude of different applications, requirements, and industries.

Utilizing specialty equipment, cutting-edge technology and innovative manufacturing processes, SCE offers its customers a vast scope of custom capabilities and metal services, including high-tech welding and fiber-optic laser cutting. This provides a truly custom-made experience centered around the highest standards of customer care, whilst its extensive portfolio presents a wide selection of standard stock enclosures and customized enclosure solutions – including NEMA Types 1, 3, 3R, 4, 4X and 12 – suited to a multitude of different applications, requirements, and industries.

With more than 60 years of manufacturing excellence, Saginaw Control continues its trajectory of innovation and improvement, providing only the very best service for its customers. To learn more about the company’s operations and plans, Manufacturing Today sat down with Scott Baldauf, Vice President, who starts by sharing the business’ backstory.

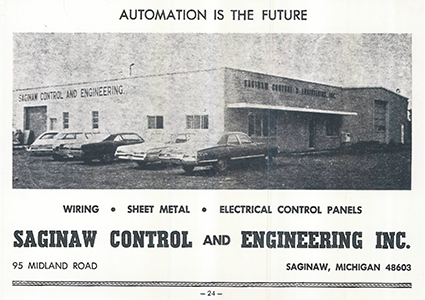

“My grandfather, a Navy veteran, founded the company in his garage in 1963 doing electrical and field service work,” Scott begins. “Soon after, he moved to his mother’s garage as it was a little bigger, and then started building the plant in the early 60s on his family farm. He started wiring electrical enclosures at this time and before long a customer approached him asking for a wired enclosure. My grandfather started calling around for parts for the project and managed to find every component but the enclosure itself. Thankfully, my grandfather who was born on a farm knew how to weld, so he fabricated the enclosure and wired it himself.

“The company then started to provide both sheet metal and enclosure fabrication as well as electrical wiring services up until the early 80s. At that point, we decided to walk away from the electrical side of the business and focus solely on sheet metal and enclosures. As we expanded, we manufactured almost any type of metal product you can name,” he continues. “Over the years, we’ve stopped producing the oddball metal products to strictly focus on enclosures and accessories that go with our enclosures and today this makes up 99.9 percent of our business. We now have six warehouses scattered across the country so that we can offer one-to-two days’ service to almost every major market in North America. Our warehouses contain approximately $40 million of inventory ready to ship. SCE continues developing our manufacturing processes and automation, and we’ve really invested in the best state-of-the-art equipment available in the industry. We have two manufacturing facilities in Saginaw, Michigan. Our East facility is roughly 330,000 square feet and our West facility is around 255,000.”

In January 2025, SCE made significant investments into its West manufacturing facility, motivated by continuing growth and commitment to innovation. Alongside an expansion, SCE has also implemented new technologies and equipment to augment its existing operations and further enhance overall quality, efficiency, and capacity.

“Earlier this year, we expanded our West facility by an additional 110,000 square feet. We’re bringing in more equipment to increase our capacity and meet our customers’ demands,” Scott explains. “We’ve installed new equipment and automation, including some new robotic technology. We’ve also added a new warehouse inside our West facility, which will help alleviate the burden on our other warehouses and increased the availability of our stock product.”

Aside from innovation and development, SCE’s corporate culture is also defined by its heritage as a family-owned business. Whilst a portion of its workforce is comprised of family members, SCE extends its arms to all employees, treating them as one big family, and fostering a caring and approachable culture.

“We still run the company like it’s a small business. We have many people who have grown with the company over the last 30 to 40 years – we even have a few individuals who have worked at SCE for over 50 years,” Scott shares. “We have a lot of people who have been with us for a long time and have grown with the company. They’re all a part of the SCE family.”

Looking to the future, further growth and expansion is on the horizon for SCE as the business continues to honor its legacy and move into the future. Despite the challenges and uncertainties sweeping the manufacturing industry, SCE is well-positioned to thrive and prosper as a proud US manufacturer.

“The electrical industry, as a whole, is a very fast-growing industry. We anticipate being able to gain additional market share in the North American market primarily, with significant growth over the course of the next five years. The new tariffs and import issues are making people second guess where they buy their enclosures, and us being based in Michigan using domestic steel has really shielded us from any tariff impacts and has greatly increased our business,” Scott concludes.