Power to the people: inside FEMA Corporation’s success story

Southwest Michigan-based FEMA Corporation of Michigan (FEMA) is a leading manufacturer of custom engineered electro-hydraulic components. Designing and producing products tailored to meet diverse application needs worldwide, FEMA’s team develops proportional pilots, two-stage electro-hydraulic valves, magnetic latching valves, on/off electro-hydraulic solenoid valves, mechanical actuators, and hydraulic system assemblies. Striving to meet and exceed its customers’ expectations, the company draws upon over 50 years of experience in delivering products that satisfy all sorts of requirements. Moreover, FEMA’s extensive experience within various industries empowers the company to offer an elaborate range of services, such as full development support with upfront analysis and full hydraulic testing capabilities. CEO, Steven Pride, divulges the key to FEMA’s continued success.

“What makes us stand out is quite simply our outstanding customer service. We are committed to being present for our customers and supporting them whilst supplying high-quality products in a timely fashion. It isn’t always easy because, although I don’t believe that the customer is always right, the cards really are in their hands. While this can prove frustrating and challenging for an organization, we recognize that ultimately, our customers enable our success and business growth. Hence, we have a duty to find ways to meet their needs and provide support. The awards bestowed upon us by our clients reflect our commitment to that duty. For example, we have received ‘Supplier of the Year’ and innovation awards from our customers, which is the highest-level certification they can grant. By supplying competitively priced, high-quality products on time, we seek to establish ourselves as a trustworthy partner,” he affirms.

Employee owned

Stepping back a few decades, Steven sheds light on FEMA’s inspiring journey. “Rocket scientist Robert Banfield, who was doing hydraulic research in the aerospace industry, founded FEMA in 1968. The name FEMA is derived from Newton’s second law ‘force equals mass times acceleration’. Robert was inspired to create the company while he was working on low mechanical hysteresis servo valves and had the idea to extend its applications to the industrial, off-highway, and automotive markets. Though originally based in Southern California, the company relocated to Portage, Michigan in 1971 to improve access to primary markets and customers’ technology centers. From a mere job shop involved in military production, FEMA evolved into a standalone company in the late 1970s and has experienced tremendous growth and expansion since then. Notably, international sales made up 30 percent of our turnover in the early 2000s, marking another significant milestone for the business. Although our operations now cover autonomy and ride dynamics, we still primarily provide electrohydraulic and electromechanical solutions to OEMs,” he says.

With the blessing of FEMA founder Robert, Steven reveals that the company is now 100 percent employee owned. “Being responsible for our own success really drives our culture, as each employee actually benefits directly from FEMA’s growth,” he begins. “In the mid-1990s, Robert laid the foundation for employee ownership, beginning with a small transaction that encompassed about one-third of the company. By 2011, we achieved full employee ownership, and Robert exited the business. I believe that one of Robert’s remarkable accomplishments was successfully transitioning the company and implementing a succession plan, allowing him to step away knowing that we would continue working diligently towards long-term success. In other words, he set the company up for prosperity, which is testament to his innovative capabilities, determination, and passion. Robert could have sold the company to private equity, but he really wanted to let the employees benefit from its success. Thus, as owners, we recognize that our mission statement involves two groups: our customers and our employees. Consequently, our culture revolves around delivering operational excellence and quality products to our clients, as this will result in the success of every employee. It is incumbent upon all of us to meet our customers’ requirements, and this customer-centric approach truly drives our culture,” he continues.

Focus on automation

Focus on automation

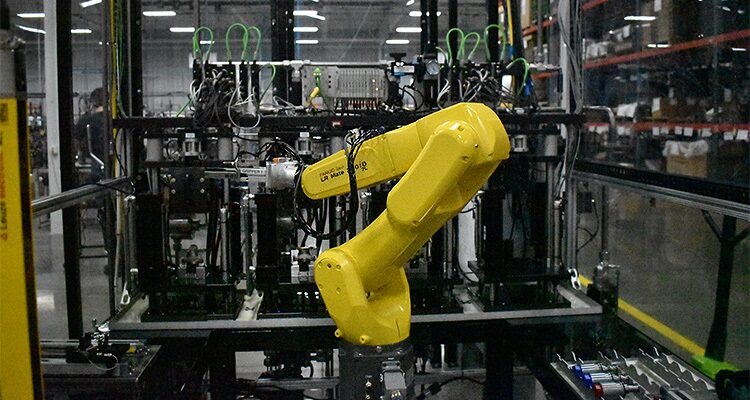

Years of thorough customer focus have empowered FEMA to broaden its geographical footprint and embrace new technologies. “Three years ago, FEMA opened a 40,000 square-foot facility in Otsego, Michigan. Prior to the opening of the new plant, our machining operations were vertically integrated and exclusively served FEMA itself. However, we decided to move our machining operations to Otsego to be a standalone entity. Within three years, we onboarded an external customer, expanding our reach beyond serving solely internal needs. So far, we are pleased with the way the site is progressing as it has achieved an IATF certification, thereby facilitating further diversification opportunities and access to a new talent pool. If we ever need to, we have the option to expand the site substantially from its current 40,000 square feet to approximately 140,000 square feet. Our Portage plant, on the other hand, spans approximately 260,000 square feet and is heavily automated. We have been seamlessly integrating automation for at least 30 years, driven by Robert’s emphasis on the necessity to protect our employees. Automation allows us to carry out standard processes without risking one of our operators’ safety. Our focus on automation also stems from our pursuit of increased efficiency, quality, and consistency. FEMA has integrated various processes, using both internal and external providers, to ensure a streamlined workflow. For instance, if a 50-pound casting arrives at FEMA, none of our operators will have to deal with it. Instead, the casting will go through a series of automated machining and assembly operations enabling us to optimize production and deliver finished products with minimal manual handling,” he adds.

As the interview draws to a close, Steven mentions FEMA’s upcoming developments. “In April 2024, our corporate office will undergo expansion to improve workforce comfort and satisfaction. It will be relocated to a modern area that will house most of our office groups including admin, supply management, human resources, and engineering. This is a step forward as our current office was built in the 1960s, and the time has come to replace it. We’re also pursuing further expansion into autonomy products and ride dynamics, because we see promising opportunities for FEMA that align with our skill set, engineering mindset, and commitment to customer support,” he ends.

With its consistent customer focus and effective employee-ownership model, FEMA is adept at fulfilling emerging needs through ongoing innovation and operational mastery.