Professor David Knowles explores how the National Materials Innovation Strategy is shaping the future of manufacturing

From energy systems to healthcare and civil infrastructure, materials innovation underpins modern manufacturing and the society it shapes. In early January, the National Materials Innovation strategy – the first-ever cross-sector strategy for materials innovation – was launched to accelerate materials development cycles and unlock untapped potential in the UK to become a leader in materials innovation and manufacturing.

Facilitated by The Henry Royce Institute with support from ScotChem, Perspective Economics, and Urban Foresight, the strategy is a call to action for UK manufacturers to embrace next-generation materials and processing techniques. By fostering collaboration across sectors, it aims to maintain the UK’s position as a global hub for materials innovation.

Facilitated by The Henry Royce Institute with support from ScotChem, Perspective Economics, and Urban Foresight, the strategy is a call to action for UK manufacturers to embrace next-generation materials and processing techniques. By fostering collaboration across sectors, it aims to maintain the UK’s position as a global hub for materials innovation.

Impact on manufacturing

Steered by the Materials Innovation Leadership Group and informed by input from over 2000 industry experts, including materials manufacturers and users, the strategy addresses key manufacturing challenges such as supply chain resilience and the need for more sustainable materials. As a result, the strategy aims to accelerate materials innovation to help deploy real-world applications including next-generation manufacturing technologies within the next decade, driving economic growth for the manufacturing sector, and increasing productivity.

Key sector opportunities

Several of the six opportunity areas for materials innovation identified by the strategy will be directly relevant to the manufacturing community:

Advanced manufacturing processes – these will be enhanced through advanced surface technologies, alloys, ceramics and specialist polymers, enabling manufacturers to create longer-lasting materials, reduce waste, and lower operational costs.

Material innovations in infrastructure and transport – breakthroughs here will improve durability and efficiency in infrastructure, contributing to a more resilient built environment.

Energy solutions – new solutions will play a critical role in supporting energy-intensive manufacturers. Technologies like green hydrogen and advanced battery technologies will lower costs for energy-intensive manufacturers and promote sustainable energy use.

Next-generation electronics – these will be critical to manufacturers as sensor technologies, electronics, and telecommunications are integral to advanced automated systems and smart manufacturing.

Packaging and consumer materials – circularity in high volume manufactured materials with be critical to a society which values its environment and critical resources, creating resilient and responsible supply chains.

By fostering innovation in these areas, manufacturers will enhance their capabilities, drive efficiency, and position themselves at the forefront of technological progress.

Cross-cutting themes

Beyond sector-specific opportunities, the strategy identified three cross-cutting themes that must be developed over the next decade to achieve a more joined-up materials innovation sector that is primed to drive the solutions required for a next-gen world.

Digitalization with technologies like AI, machine learning and the adoption of Materials 4.0 – the digitalization and automation of materials science to accelerate the discovery, development, optimization of new materials and materials reuse (digital fingerprinting) – will enable manufacturers to streamline operations, reduce waste, and accelerate time-to-market for new products. Investing in digital manufacturing technologies like AI, big data, and cyber-physical systems will be crucial to stay ahead of the curve and make the most of emerging materials innovations.

Growing regulatory pressure to have a sustainability and circular economy first approach is driving manufacturers toward recyclable materials and circular design to align with net-zero goals. Addressing material shortages, such as reliance on scarce metals for green technologies like hydrogen production, will require a resilient, sustainable supply chain and cross-industry collaboration.

Finally, the strategy highlights the importance of translation and commercialization to ensure materials innovations efficiently scale discoveries into real-world applications. At the same time, clear regulatory policies will support innovation while maintaining quality and safety standards.

Implications for UK manufacturers

A robust materials roadmap is key to accelerating UK manufacturing, which as of 2024, employed 2.6 million people, representing over nine percent of total UK employment and 8.8 percent of total UK economic output (£208.2 billion GVA). Currently, the 2768 UK companies active in materials innovation employ between 35,500 and 52,000 people in materials-specific roles facilitating up to 18 other jobs within UK materials innovation companies. The GVA associated with these materials-specific jobs is estimated to be up to £4.4 billion. The strategy estimates that a commitment to materials innovation could double the number of materials-specific job roles by 2035. Investing in upskilling the workforce will help to ensure the sector’s long-term sustainability, while strengthening the UK’s position as a global leader in materials innovation and by extension, manufacturing.

Access to cutting-edge materials will enable manufacturers to enhance product performance, expand their global market reach, and improve efficiency. Simultaneously, materials innovation will strengthen supply chain resilience, mitigating disruptions and reducing dependence on scarce resources.

Collaboration is central to this strategy, breaking down silos between materials science, manufacturing, and industry. Manufacturers can actively shape the next phase of materials development and remain ahead of global competitors by fostering partnerships across research institutions, businesses, and policymakers.

A decade ahead of growth and innovation

The National Materials Innovation Strategy offers manufacturers a unique opportunity to accelerate innovation, enhance sustainability, and expand their market reach. Over the next decade, it will drive transformative, materials-led growth, positioning UK manufacturers at the forefront of emerging industries. To stay competitive, manufacturers must remain engaged and adopt advanced materials, upskill their workforce, and form strategic partnerships. More than a roadmap, the strategy is a rallying cry for the wider sector to unite in building a future-proof materials ecosystem and securing the UK’s global sector leadership.

Interested in contributing to the implementation of the National Materials Innovation Strategy? Register your interest today by emailing: info@royce.ac.uk

David Knowles

www.royce.ac.uk/collaborate/innovationstrategy

David Knowles is CEO of the Henry Royce Institute and is a Professor in Materials Engineering. He is a specialist in the structural integrity of materials from extended roles in industry and academia across sectors including nuclear, renewables, oil and gas, aerospace and transport.

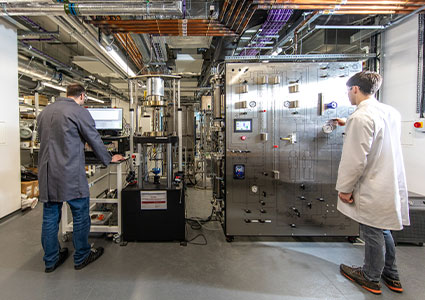

Royce is the front door to the UK materials research and innovation community open to academia, industry and the public. Its research tackles some of the most pressing challenges facing today’s society, from providing energy for future cities to decarbonization and new recyclable materials.

Its materials facilities and research expertise are available to academia and industry alike. Whether you are a researcher, a large company, or an SME, Royce can help to meet your materials needs.