Redline Plastics

Designed for growth

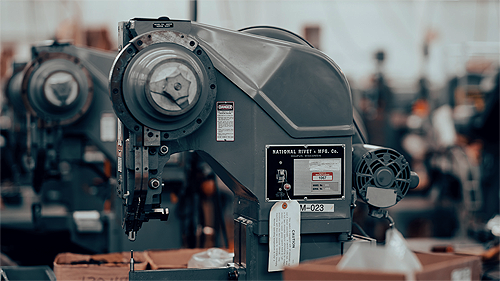

Chuck Webster, President & CEO at Redline Plastics (and part of the Webster family, which has owned the company in its various forms since 1975), gave Manufacturing Today the story of the business, which today is a specialist in commercial sewing, plastics rotational molding and plastics vacuum forming. “On the commercial sewing side, we manufacture motorcycle covers, leather saddlebags and other similar products for original equipment manufacturers (OEMs),” he began. “In aftermarket powersports our products are sold under our own brands – Dowco Powersports is the USA’s leading high end aftermarket motorcycle cover brand – and our motorcycle saddlebags and other items are sold under the Willie & Max name. Our own brand has been a huge focus of late and helps us to ensure that we are keeping all areas of our business engaged and active.”

The Rotational Molding portfolio of products created by Redline is very extensive, meeting the needs of various sectors and including a huge variety of options from pontoon boat furniture bases to dog kennels, construction equipment parts and porta potty components. “For Vacuum Forming we create powersports roofs for OEM UTVs, which are sold to multiple companies for private label brands,” continued Chuck. “Marine components, like dash panels and light housings, electronics enclosures and fiberglass reinforced skid steer hoods are also manufactured in-house and in addition, we offer Line Bending for powersports windshields and roofs.

“We are the only company that I know of that has rotational molding, vacuum forming, cut and sew, and the ability to fiberglass-reinforce-plastics all under one roof. This gives us a unique competitive advantage over other rotomolders as we can make and assemble parts that require all of our in-house capabilities and have those products leave our facility fully finished on their way to the end consumer. This makes it easier for our customers’ buyers because they do not have to source multiple different manufacturers to make their product, they can come to a one-stop-shop. We also source all components necessary to fully assemble, kit, and complete products. We have great suppliers and love trying new methods and materials so we are constantly on the cutting edge of new technology in the market.”

The manufacturing services provided by Redline are undertaken in its sophisticated, state-of-the-art facility in Manitowoc, Wisconsin, which is already undergoing a large expansion only a year-and-a-half after the new facility was constructed. Ground was broken in March 2021 for an additional 103,000 sq. ft., which is due for completion by September 2021. “We have outgrown our current space, which is constricting our process flow. With the large amount of new business coming in, the new space will alleviate and de-clutter the facility, which will enhance throughput and increase productivity even further,” Chuck explained.

This additional space will be used for a new, very large rotational molding machine with space to comfortably add three more. The rest of the new expansion will be used for larger secondary processing and CNC trimming in addition to increased raw material and finished goods storage. “We purposefully designed the facility in a way to efficiently move hot air out of the building to create more consistent air temperatures for employee comfort and to improve product quality. The inside of the building is all white; this allows for lower heat absorption and for a brighter work environment to improve product quality. The machines were laid out to enable efficient flow, from tool change outs to loading powdered resin to trimming and final assembly to shipping. This is a process we continue to perfect.”

Chuck continued with some further differentiators that make Redline stand out from the competition, starting with team and culture. “We have significant technical expertise in all areas of our business and at all levels. From operator/sewer through to top management, we have employees who are experts in all the different core areas of our business, such as engineering, helping with new product design-for-manufacturability, tooling design and sourcing, both foreign and domestic, logistics and vendor-managed inventory. You typically don’t find that in a business of our current size, but it is making a significant difference in our ability to grow rapidly.”

The next area Chuck identified was Strategic Risk Taking, where he noted that Redline has been successful at managing its risk while onboarding new equipment as well as training new team members. “This is so that, by the completion of the new machinery installation and employee training, we have customers to fill the new capacity. This makes us attractive to customers with larger books of business who are not being serviced by their current supplier,” he explained. “Many businesses wait to justify capital expenditures for new machinery until they reach 80 percent-to-100 percent capacity. Given the current constraints on many supply chains, this concept greatly handicaps growth. We take calculated risks trusting that we will continue to find great customers/partners to help fuel their and our growth.”

From Chuck’s description, it was clear that Redline must devote extreme efforts into innovation and the process of new product development, in order to continually produce and improve on its impressive line-up. “We have full scale engineering services on both the plastics and cut and sew side of our business,” he confirmed. “From designing our own concepts/projects to helping our customers bring their innovative ideas to life, we provide a one-stop-shop and can handle new projects from napkin sketch through direct shipment to end user.”

Collaborative approach

A new range of motorcycle ratchet covers and a line of folding UTV windshields have both been released recently, and Chuck also gave another example of Redline’s collaborative customer approach. “A company asked us to assist with the design of a great concept – a cargo container that was to be used by the military to deliver specific cargo loads to strategic locations from an airplane,” Chuck elaborated. “The soldier would be attached to the cargo container and when both soldier and container hit the ground, the case would be opened to get the contents to their immediate strategic location. We were able to provide design engineering assistance to make it manufacturable and incorporate all of the ‘bells and whistles’ to help them get the end product they wanted, which was a case that was waterproof, could carry up to 1000 pounds and withstand the force of hitting the ground at a relatively high speed, and fit the rail systems of our military’s standard cargo drop system. This project was a combination of educating our customer on materials and our expertise in designing a working product that met the needs of our armed service members.”

attached to the cargo container and when both soldier and container hit the ground, the case would be opened to get the contents to their immediate strategic location. We were able to provide design engineering assistance to make it manufacturable and incorporate all of the ‘bells and whistles’ to help them get the end product they wanted, which was a case that was waterproof, could carry up to 1000 pounds and withstand the force of hitting the ground at a relatively high speed, and fit the rail systems of our military’s standard cargo drop system. This project was a combination of educating our customer on materials and our expertise in designing a working product that met the needs of our armed service members.”

Redline is also happy to trial new and unique resins for customers to improve costs, and offer suggestions during initial product design to help make durable, unique and manufacturable products for the use intended.

“We have several design engineers who have come together to deliver 20+ new products under our branded lines to market this year alone,” added Chuck. “This is in addition to servicing our OEM customers who continue to have significant and specific design needs. We have internal processes that are followed for new product development and are geared towards our own manufacturing capabilities. From concept design through testing, our innovative engineers constantly deliver fresh ideas that also require unique testing parameters to ensure the products are ready and safe for the market.”

As Chuck was describing the power behind the company’s success, he frequently referred to the staff and people employed by Redline. Having been named as one of the ‘Best Places to Work’ by Plastics News in 2021, the business prides itself on its culture and family atmosphere. Chuck gave some more details about the people philosophy. “We researched how to create a high performing culture and that led us to introduce our guiding cultural behaviors. Rather than the typical company mission, vision and values, which we think are mostly meaningless and speak to a small portion of any one business, we elected to create a set of values that we expect our team members to exhibit while going about any task,” he described. “Instead of traditional corporate speak, we made them memorable and used everyday language so that everyone throughout our organization understands and can live them. For example, instead of saying treat people kindly, we say ‘Don’t be a Jackass’. Another favorite is, instead of saying work as a team, we say ‘The only I in Team is hidden in the A-hole’. We printed a wall-sized graphic of these behaviors for our lobby and production floor. Job applicants and customers have raved about how awesome they are and cited them as reasons they want to work with us. We have had many people take photos of the wall because it is so unique. It shows we are real people that shoot straight, which is refreshing.

“We believe we have a company culture that speaks to all employees and we try to have fun with our work family. The top reason people give for why they like working at Redline is ‘the people I work with’. If it wasn’t for all the hardworking people here at Redline Plastics, we wouldn’t be the company we are today.”

This approach is combined with a hiring strategy that employs hardworking supervisors and managers who have a connection to shop floor employees and will put them first. “We recognize that by meeting the needs of our team, they will help us to reach our goals. This mentality has enabled us to increase our workforce from 85 employees to 157 employees in six months. It is their leadership that helps to guide us in our direction of incremental growth,” added Chuck.

Skyrocket in demand

This increase in numbers was necessitated by a skyrocket in demand for products during the Covid-19 pandemic. Many of Redline’s parts were deemed essential and cannot be made from home. Keeping staff safe was a priority. “Our preventative measures included daily temperature taking, increased cleaning of high touch surfaces and masks required in the building. We also strongly encouraged people not to come to work if they felt sick or had immediate exposure to someone with Covid-19. During that time, we had minimal cases of Covid-19 affecting our employees and had no impacts towards normal and ordinary business operations. Additionally, we tried to limit support staff from interacting with floor employees to help keep our main workforce safe.”

Continuing on this growth path is at the top of the agenda for Chuck and his team, and this is always tempered with the underlying aim to ‘improve our workplace and the benefits we offer to employees.’ “We want to continue our ascent up the domestically ranked list of rotomolders and continue to be recognized by our customers as the rotomolding, vacuum forming, and cut and sew house that can deliver a full-scale menu of options to meet their needs,” he confirmed. “Additionally, we would like to remain known as the employer of choice in our area and further our goal of taking care of our employees and giving back to the community. If there is one thing all businesses are learning first-hand, it is to treat your employees right in all areas of your business. You have to create and nourish an environment where the right people want to work.”

Redline Plastics

www.redlineplastics.com

Services: Rotational molding, vacuum forming and industrial sewing company