Risks and Safety in Fiber Laser Manufacturing

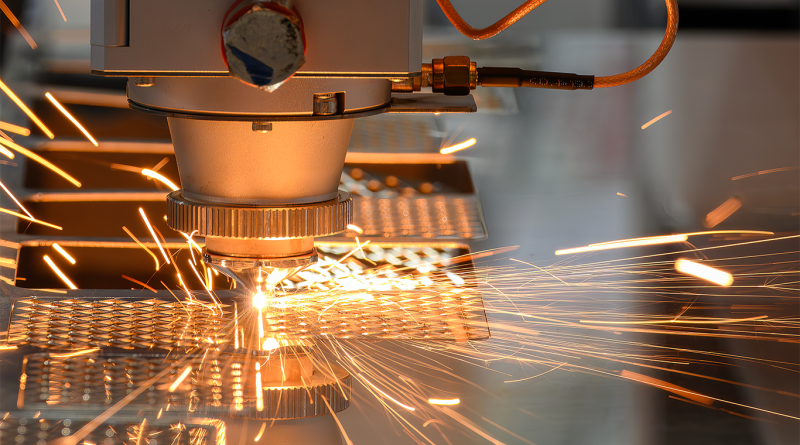

The metal manufacturing industry has undergone a transformation with the advent of technologies like fiber lasers, which have greatly improved production efficiency and precision. Despite these benefits, such advancements have also introduced notable safety challenges. Fiber lasers, despite their superior performance, pose risks to operators due to their high-power output and the invisibility of the near-infrared beams they emit. While companies like AMADA integrate safety into their equipment, many manufacturers offer cheaper alternatives that lack adequate safety features, exposing operators to potential injuries such as eye damage and skin burns.

This inconsistency in safety measures across the industry has underscored the need for stricter regulation and oversight. Manufacturers adhering to rigorous safety protocols are often competing against those cutting corners by offering cost-effective but hazardous equipment. This creates a dangerous environment where operators using low-standard machines face higher risks of accidental exposure to laser beams, which could cause irreversible retinal damage or worse. It’s vital to purchase equipment from reputable manufacturers that prioritize user safety, like AMADA.

Understanding the Risks of Fiber Lasers

Fiber laser technology offers numerous advantages in metal fabrication, including high-speed cutting and the ability to work with various materials such as steel and aluminum. However, the same qualities that make fiber lasers effective also contribute to their dangers. Fiber lasers typically operate in the near-infrared spectrum, rendering the beam invisible to the human eye, increasing the risk of retinal burns, which can lead to blindness. The eye’s cornea can focus this light onto the retina, causing severe damage even without direct exposure.

Unlike CO2 lasers, which emit visible light, fiber lasers can cause harm even from indirect exposure or reflection on metal surfaces. Safety guidelines established by bodies such as the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI) provide essential measures, including protective eyewear, controlled work areas, and machine interlocks. However, many low-cost machines fail to meet these safety standards, putting operators at risk.

AMADA’s Approach to Safety

AMADA takes a proactive approach to safety in the metal fabrication industry, embedding advanced safety mechanisms into its fiber laser systems. One primary concern with fiber lasers is the potential for eye injuries, as exposure to near-infrared light can cause retinal burns and permanent vision loss. AMADA’s equipment includes automatic shutdown features that prevent the machine from firing unless the welding torch is positioned correctly. These features, along with sensors that detect back reflections or incorrect beam outputs, significantly reduce the risk of accidents.

AMADA’s national sales manager, Jan Halfar, emphasized that safety is paramount in their product design. The company uses full-face welding helmets rated for fiber laser wavelengths, offering far more protection than standard laser safety glasses. AMADA also ensures that their machines cannot fire unless in contact with the material, further minimizing risks to operators and bystanders.

Beyond equipment design, AMADA prioritizes customer education, ensuring that clients are well-informed about safe machine operation. This focus on safety and training has helped AMADA maintain a strong safety record, with no reported accidents involving their fiber laser welding machines. By combining innovative technology with comprehensive operator education, AMADA sets a high standard for safety in the metal fabrication industry.

The Need for Stricter Regulatory Enforcement

While AMADA leads by example in ensuring the safety of its laser equipment, the broader industry faces challenges due to inadequate regulatory enforcement. Many low-cost fiber laser systems on the market lack the comprehensive safety features that AMADA incorporates. These cheaper alternatives often bypass critical safety standards, putting operators at risk of severe injury. The issue lies in lax enforcement of existing regulations and insufficient oversight of imported equipment.

Jan Halfar has raised concerns about the lack of government oversight in enforcing workplace safety regulations. In many cases, the responsibility for safety falls on operators rather than manufacturers or importers of substandard equipment. This lack of accountability allows unsafe machines to flood the market, creating ongoing risks for workers in metal fabrication.

While OSHA and ANSI provide clear guidelines for laser safety in industrial settings, enforcement varies, allowing unsafe machines to circulate. The need for stricter oversight is becoming more urgent as laser technology continues to expand across the industry. Without robust enforcement, manufacturers that prioritize cost-cutting over safety will continue to put operators at risk. AMADA has been vocal in advocating for better regulation and oversight, ensuring all manufacturers adhere to high safety standards.

The Future of Safe Metal Manufacturing

As metal manufacturing evolves, safety will remain a critical concern, especially with the growing use of fiber laser technology. AMADA’s commitment to developing safety-first equipment sets a high bar for the industry. Their fiber laser systems, with built-in safeguards and advanced protective gear, show that safety can go hand in hand with innovation and efficiency. By prioritizing operator protection, AMADA not only protects workers but also fosters a culture of responsibility and care in metal fabrication.

Collaboration between manufacturers, regulatory bodies, and industry leaders is essential to ensure all workers benefit from the same high safety standards. Stricter enforcement of safety regulations is crucial for creating an industry where efficiency and innovation coexist with operator safety. AMADA’s leadership in this area provides a blueprint for the future, where safety remains a top priority for manufacturers and regulators alike.

Sources: