Rohrer Corporation has built a strong foundation for growth alongside developing sustainable solutions

When we last spoke with packaging specialist Rohrer Corporation (Rohrer) back in 2023, the company was focused on expanding its presence and capabilities through mergers and acquisitions (M&A), with the support of financial sponsors, Wellspring Capital Management (Wellspring).

18 months on, and Tim Swanson, Rohrer’s CEO, joins Manufacturing Today to update us on the company’s innovative product additions, factory-focused investments, and its latest M&A activity. Using state-of-the-art manufacturing technologies, Rohrer continues to provide innovative and increasingly sustainable packaging solutions that offer industry-leading speed, quality, and value.

“Since we last spoke,” Tim begins, “the packaging industry has dealt with a challenging backdrop of continued demand signal correction following the Covid-19 pandemic, subsequent supply chain challenges and inflationary pressures. The first two events increased demand as people were concerned about running out of essential items, but when the inflationary period then hit, inventories across the value chain that had been inflated in ours and our customers’ systems adjusted downward and back toward normal demand levels.

“We’re now seeing our demand signal return to more of an expected level, and while inventories have corrected themselves, we’ve focused on getting a strong strategy in place to support growth and investment moving forward. We’ve specifically focused on market penetration and operational excellence to accelerate both our sales and revenue generation footprints, as well as profitability. We’ve brought new talent into the business and expanded and realigned our operational functions with a view to improving internal efficiency and better leveraging existing assets.

Sustainable solutions

“Wellspring continues to be supportive of our platform-build aspirations, and when they invested in the company in 2021, they had a vision to drive an aggressive M&A strategy,” Tim continues. “However, we needed to review our operational framework and create a strong, stable foundation capable of supporting such accelerated growth and expansion. We’re now fully into our targeted M&A strategy, taking advantage of opportunities as the market presents them.

“We’ve got a great geographic spread, but we do see opportunities to build our capabilities closer to the West Coast. We have a facility in Arizona, for instance, but we’re looking to scale our operations in the region through M&A activity. M&A is also a great vehicle for us to enter the pharmaceuticals market in the future, as there are specific requirements around materials and production conditions.”

Turning to products, Tim explains Rohrer maintains its industry-leading position through innovative product development and unparalleled quality. “Our two core products are blister cards and clamshell packaging, but we’re increasingly expanding into folding cartons and individual cartons in the health and beauty market,” he shares. “As sustainability becomes increasingly important among end users, retailers, and investors, we’re innovating to provide packaging solutions that meet both marketing requirements and sustainability demands.

“Representing our commitment to cater to evolving packaging preferences and reduce waste and natural resource consumption, we’ve leveraged our strategic partnership with Clearwater Paper to create EcoVolve-30™, our new sustainable paperboard product line made from 30 percent post-consumer recycled (PCR) fiber. Unlike other paperboards with high levels of PCR content, EcoVolve-30™ provides excellent print performance and durability, with high definition, brightness and color balance. We’re already seeing incredible interest in the product. EcoVolve-30™ C1S (coated one side) blister board is the first series launch in the new line, EcoVolve™. The new EcoVolve range will enable customers to enhance their eco-friendly credentials without sacrificing quality and durability.

“In the same way we’re finding innovative and sustainable solutions for our paper packaging, we’re also looking at our plastics business to find alternative materials or add PCR content to our thermoformed clamshell products. There are some new innovations that aren’t commercially available yet, but we’re also conducting our own research and development around food-grade plastics.”

Cutting-edge technology

On the topic of innovation, Tim reveals more about Rohrer’s three-pronged strategy. “Our innovation falls into three categories: supplier led, customer led, and company-led,” he states. “Firstly, we work with our supply network to create new technologies, products, and processes, and our new EcoVolve™ range is a great example of such supplier-led innovation. We also have a customer-led approach, where we listen to our customers’ problems or initiatives and then create a solution that meets their needs. Lastly, there’s company-led innovation. At 51 years old, Rohrer has a team of subject matter experts who leverage our extensive experience and industry knowledge to enhance new product development.”

On the topic of innovation, Tim reveals more about Rohrer’s three-pronged strategy. “Our innovation falls into three categories: supplier led, customer led, and company-led,” he states. “Firstly, we work with our supply network to create new technologies, products, and processes, and our new EcoVolve™ range is a great example of such supplier-led innovation. We also have a customer-led approach, where we listen to our customers’ problems or initiatives and then create a solution that meets their needs. Lastly, there’s company-led innovation. At 51 years old, Rohrer has a team of subject matter experts who leverage our extensive experience and industry knowledge to enhance new product development.”

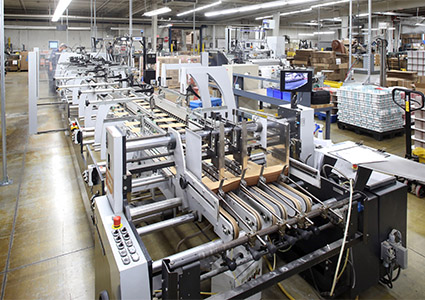

As our conversation continues, discussion turns to the company’s factory-focused investments in technology alongside its ongoing M&A activity. “Whether it’s thermoforming, printing, or die cutting, we live in a world where there are several options for operating more effectively or efficiently using smart technology,” Tim says. “Our printing presses run extremely fast, sometimes producing upwards of 14,000 sheets per hour. We’re investing in smart scan technology that allows us to set a base standard upon which all products are reviewed in real time to ensure the quality of the graphics, inks, and colors.

“We’re at the start of our smart factory journey, and we’re currently exploring the option of adding automated packing capabilities. We run different products through several processes at any given time, so we can save an incredible amount of time by implementing automated packing technology capable of handling multiple products and geometries.

“Since we last spoke, we’ve also invested further in our internal system, The Rohrer Edge,” he adds. “The Rohrer Edge is focused on simplification and focus that ultimately fosters growth by streamlining our operations and enabling the use of technology and automation to enhance the way we serve our customers.”

Tim goes on to share his thoughts on Rohrer’s future. “We’ve got a strategy in place that addresses where we want to be and how we want to grow, and we’re now focused on building that platform, continuously adding new products and capabilities to better serve our customers. We have a fair amount of capital to deploy, so our M&A activity will continue, particularly as we strive to offer additional capabilities.

“We’re also interested in strengthening our presence in the folding carton and rigid box markets, which parallels nicely with our existing product portfolio. These products are predominately used in promotional or seasonal products and in the health and beauty industry. In the longer term, we’re also looking at the labels market, which is constantly expanding and spans a wide array in terms of both materials and customers.

“Our goal is to double the size of the business over the next two-to-three years,” Tim concludes. “Doing that will make Rohrer a more valuable partner to our customers”.