Rohwedder

Rohwedder’s vision of success

Established in 1956, Rohwedder AG is an international leader in state-of-the-art automation engineering and technology.

It develops and manufactures systems for electronics production, assembly and micro-assembly technology as well as vision technology, through its 11 locations based in Germany, France, Canada, USA, Mexico, China and Australia.

The company’s automation lines are used in numerous sectors of industry including automotive supplies, telecommunications, electronics and medical engineering.

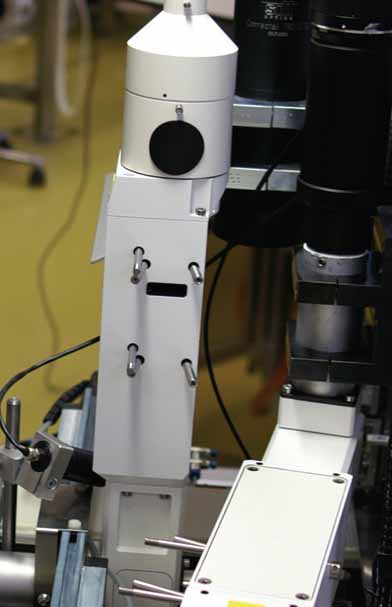

At its plant in Markdorf in southern Germany, Rohwedder develops and manufactures vision automation technology for a range of vision applications focusing on assembly and inspection. Head of sales and marketing Werner Groszmuk explains how this aspect of the company operates: “We integrate components to complete solutions for all kinds of vision applications, particularly for assembly sections and surface inspection. We also specialise in robot guidance systems and dimensional measuring systems in both 2D and 3D.”

At its headquarters in Bermatingen, Germany, there is a focus on developing specialised solutions for assembly automation lines to meet specific customer requirements because Rohwedder believed that offering a customised service is important. “We manufacture dedicated projects, always producing customised solutions – each project is unique,” explains Werner. “We may utilise some portions of previously completed work but generally we manufacture specifically for one customer, which makes our supply chain and logistics quite complex.”

Continuing, he adds: ”One of the major aspects of the supply chain is managing the co-ordination and integration whilst allowing Rohwedder AG Competence Center Vision Technology to do a feasibility study together with the customer in order to make sure that the application required is attainable. This willingness to delve deeper in order to deliver what the customer really needs is one of our strongest points.”

The company evolved from Rohwedder KG, which operated within the machine building industry producing precision tools, and for many years after its arrival in 1956 Rohwedder AG focused on the production of speciality machinery. In 1981, Joachim Rohwedder, the son of co-founder Hans Rohwedder, became managing director and steered the company towards automation technology. The primary focus was on high quality assembly systems for the automotive industry and entertainment electronics.

Executive vice president Frank Wagner believes Rohwedder is a unique company providing highly modern solutions: “It is very difficult to compare us with anyone else in the market because our strength and one of our core competencies is in vision technology, and this is a very new area. Also, we have within our company five other competence centres – assembly technologies Europe and North America, micro technologies, assembly and test technologies for electronics production solutions and surface mount technologies – which allows us the necessary manufacturing technology to provide our customers with turnkey solutions. We can provide vision technology along with the complete mechanics necessary, which is our unique selling point.”

Continuing, he adds: “Our competitors in vision technology have around 25 to 50 employees but our whole group has 580, meaning we can handle larger projects and have all that we need within the group to fulfil the complete manufacturing of every product, which makes one-stop shopping a reality.”

The vision technology automation industry is dynamic and comparatively embryonic when viewed alongside other industries, which provides many opportunities for growth. Frank explains: “The vision technology market is in a very good position. It is steadily growing due to the fact that vision technology is extremely new, unlike the automotive or mechanics industries, which are at least 50 to 70 years old. Vision technology only has about 15 years behind it and our customers constantly comment on how much vision technology has changed just over the past two years.”

Frank continues: “Only 25 per cent of all possible applications are currently developed because the market is still very young and the industrial PCs for cameras with high resolution have only been on the market for two to four years. Ten years ago, even if we could understand vision technology, we couldn’t apply the knowledge simply because the current industrial PCs and cameras were not available. Therefore we couldn’t buy components or hardware to fulfil these applications.“

As a manufacturer of innovative technology, R&D is key to Rohwedder’s success: “We invest a great deal in R&D simply because vision technology is new with new applications and requirements,” Frank comments. “We are already partners for a lot of customers with highly sophisticated AOI (Automatic Optical Inspection) systems and we want to work harder to cultivate this development and recruit more partners.”

Werner recognises the challenges facing Rohwedder in the future but feels confident that the company can overcome them: “In vision technology, the major challenge is to standardise certain areas because although we customise based on requirements, standardising where possible makes life easier for our partners. Also, the miniaturisation of products has reduced the size of the field of recognition meaning more sophisticated technology is needed.“

Looking to the future, Frank speaks about the company’s main goals: “Our vision is to see our partners think about a new product and then instinctively invite us to assist in product development. This will give us a direct input that, hopefully, will result in Rohwedder acting as vision automation partner every time.”

Werner concludes: “We think of our customers more as partners and one of our main targets is to provide success for all of them through our excellence in vision automation.”

Rohwedder

Products: Automation technology

Sites: Europe, North America, Asia and Australia

Employees: 580

www.rohwedder.com