Special Metals Wiggin Ltd

A new beginning for Special Metals

Special Metals Wiggin traces its roots back to Henry Wiggin and Company Limited, a business formed by Sir Henry Wiggin in the mid 1800s to manufacture specialty metal products.

This company was ultimately composed of metal forming operations in Birmingham, Hereford and Glasgow.

The Wiggin operations then became part of the International Nickel Company in 1929 when International Nickel merged with the British Mond Nickel Company to form the International Nickel Company of Canada (now known as Vale Inco).

After a significant number of years operating successfully within the industry, Special Metals experienced some challenging times, which saw the company under threat from bankruptcy.

Ray Stone, managing director for the business joined Special Metals Wiggin four years ago and has helped lead the company back to profit. Looking at the company’s recent history, he comments: “For most of last century we were owned by Inco – manufacturers of processors for nickel alloys. We became part of the US organisation Special Metals in 1998 and in 2002, following two dramatic events, the parent company filed for Chapter 11 bankruptcy protection, which saw Wiggin go through a long restructuring exercise.”

After the 9/11 attacks in New York, which resulted in a major fall in aircraft building, and the collapse of the power giant, Enron, which affected the land based gas turbine industry, Special Metals Wiggin’s orders reduced significantly as a large amount of its business was in these two areas.

Ray continues: “We completed the restructuring process in 2003 and since that time we have been developing and growing the business. Furthermore, another step forward for the company was when it became part of the US firm Precision Castparts Corporation. This organisation is now working with us and driving us forward in terms of growth and business performance. We are getting tremendous support from the parent company and they are helping us develop our business improvement programme.”

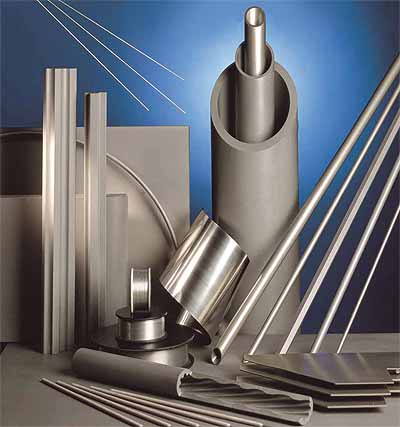

Today, Special Metals Wiggin is again a thriving business and over the last four years the company has doubled its sales turnover to approximately £160 million. Based in Hereford, the company is the major European production facility in the Special Metals group. Using air and vacuum melting, vacuum arc and electroslag re-melting, powder metallurgy, forging, extrusion, hot and cold rolling, and cold drawing, the business makes a comprehensive range of nickel alloys in most standard wrought forms. These include ingot, billet and bar, extruded sections, pipe and tube, flat products (plate, sheet, strip, and foil), and wire and wire rod.

As further evidence of the business’ success in the special metals industry over the last few years, the company has recently achieved a major new supply deal worth £120 million over the next six years. This deal is a £20m a year contract to supply US firm, Eaton, with the alloys its needs to make its world class automotive engine valves.

Traditional metals used to make the valves can no longer cope with the high temperatures of modern diesel engines, which burn at a higher temperature to improve efficiency and reduce pollution. This opens up a new market for the specialist alloys made in Hereford. Eaton is already a leading producer of diesel engine valves worldwide and expects to substantially increase output over the next three years.

Ray comments: “As a result of winning this contract, our parent company has approved a scheme to build a new rod mill, which is being manufactured in Sweden and will be commissioned in December 2008. Here in Hereford, we also have a unique low cost melting, forging and extrusion process, and this complimented with the new state-of-the-art rod mill will put us in a very strong position to compete in the global market.”

He continues: “We are currently in the process of upgrading a significant amount of our equipment. This four-year programme will see our manufacturing facilities both improved and modernised, which will enable us to operate to world best practice. Once all of this is completed we will be looking to expand our business further.”

Special Metals Wiggin’s manufacturing facilities in Hereford are also accredited to quality management system ISO 9001:2000 and in addition the testing laboratories are accredited by UKAS. Furthermore, approvals from individual customers include those from Aérospatiale, ASEA-ATOM, British Nuclear Fuels plc, DCAN, Fiat Aviazione SpA, MTU GmbH, Rolls Royce, SNECMA, Statoil, and VdTÜV. The company also has EN/AS/JISQ 9100 and PRI/Nadcap Approval for heat treatment, nondestructive testing and materials testing.

Special Metals Wiggin has a long history of designing new alloys and the organisation is constantly investing in the development of new solutions for critical applications. To help develop its product range, the business works very closely with its customers. By establishing close relationships with its clients Special Metals can understand its customers’ needs – this helps the company to become the supplier of choice in the market.

Special Metals Wiggin supplies a wide range of industries, including automotive, land-based gas turbines, oil and gas, chemical and energy. The company also operates in a number of different countries on a global basis. One of the business’ strong markets at the moment is China. Ray comments: “We are able to compete with a number of products in the Chinese market. Our strategy is to target certain markets for certain products, as we understand that some solutions are more successful than others in particular countries.”

Having experienced first-hand how tough the industry can be, Special Metals now wastes no time looking back and concentrates on the what the future can bring. Ray explains: “The manufacturing environment in the global market is always challenging but the important point is to understand or work within the challenges. There are factors that we can control ourselves and this is what we concentrate on. We don’t spend time complaining about the factors we can’t control, such as the price of raw materials and the exchange rate, because these will be present no matter what we do. We focus on our employees, our business processes and our facilities, as these are the factors, which drive our company forward.”

One of the main factors that has enabled Special Metals to turn its fortunes around is its committed workforce. Ray continues: “We have an excellent workforce here in Hereford – I have worked in the metals industry for over 40 years and this is by far the best team I have ever had the pleasure of managing. To achieve this, we spend a significant amount of time training our employees at all levels, from management to the shop floor. In addition, we have an extremely good apprenticeship scheme – in fact last year we were runners up in the National Apprenticeship Awards. We also work very closely with a training organisation, and together we look at ways to improve the quality of our workforce.”

He continues: “Furthermore, we have a phenomenal management team – they all understand the strategy and objectives of the company going forward and are committed to overcome any challenge and to continue to achieve further growth.”

With a strong workforce, complimented by a continually improving product range, Special Metals Wiggin has again made a name for itself in the special metals industry. The recent achievement of the contract with Eaton is evidence of this, and now with significant investment into its production facilities, the company looks set to continue pushing forward.

Ray concludes: “My short-term and long-term goals are to grow the business both in terms of volume and profitability. When our parent company filed for Chapter 11 bankruptcy protection there was a huge risk that the company would go under but through our dedicated team of employees we showed the banks that we had a viable business going forward. Today, we understand that we are working within a very challenging manufacturing industry and there are issues to deal with on a daily basis but our main strength is that we just get on with it. People keep telling me the manufacturing industry in the UK is dying – all I can say is come to Hereford and you will quickly see it isn’t.”

Special Metals Wiggin Ltd

Products: Alloys

Sites: Hereford

Employees: 700

www.specialmetals.com