STOBER Drives Introduces ServoStop: Revolutionizing Safety with Redundant Braking Power

When an assembly line needs to stop immediately because of a power failure or hazardous situation, the safety of employees and equipment is only as strong as the braking system. With a goal of increasing safety throughout the manufacturing industry, STOBER Drives launched ServoStop, a revolutionary holding brake that provides redundant braking power.

“This is a product ahead of its time,” Product Engineer Tyler Mattingly says. “Safety is very important today and what ServoStop does is stop a vertical load from dropping on someone. Everyone is concerned about employees wearing personal protective equipment, but we see this new area of safety becoming an industry standard.”

The Maysville, Ky.-based company has specialized in industrial gearboxes for more than 80 years and has more than 30 years of motor expertise. Its Servo solutions range from planetary gearheads to helical bevel gearboxes to hollow bore motors to rack and pinion solutions. “We have a wide breadth of offering and that’s what makes us special,” Mattingly says. “We are very modular with what we do and that allows anything new we develop to be incorporated throughout the entire product range.”

For example, ServoStop is not only designed for Servo brand products, but can be used on any other gear reducer STOBER offers. “We are very versatile and offer a number of products that get the job done for you because we have a wide variety of products to optimize solutions for your machine or specific application,” Mattingly explains. “We might have five products that do the same thing, but there is one that will be best suited for your needs.”

STOBER provides solutions to a variety of industries including aerospace, automation, automotive manufacturing, beverage, printing, food processing, machine tool, material handling, medical, packaging, plastics/composites, process/valve control, robotics and semiconductor. “Our customers look for a gearbox that will last for years and give them no issue or maintenance problems while others are looking for a precise gearbox able to handle high speeds, for example,” McCord says.

Brake with Confidence

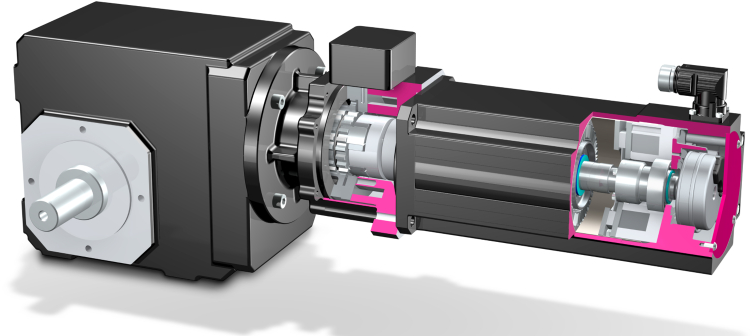

STOBER ServoStop is incorporated into the gearbox input. “The way we are implementing this into our gearbox results in a number of benefits,” Mattingly explains. “For one, it makes the overall package a lot shorter than you can buy elsewhere. With our application, you have the gearbox, ServoStop and motor, but our competitors need a gearbox, input adaptor, safety brake and motor, which is quite a bit longer. Because we can put ServoStop directly in the gearbox, we can use a smaller brake to generate more braking torque. ServoStop acts as the input to our gearbox, which allows the motor to be removed from the unit without the load/axis moving.”

STOBER ServoStop is incorporated into the gearbox input. “The way we are implementing this into our gearbox results in a number of benefits,” Mattingly explains. “For one, it makes the overall package a lot shorter than you can buy elsewhere. With our application, you have the gearbox, ServoStop and motor, but our competitors need a gearbox, input adaptor, safety brake and motor, which is quite a bit longer. Because we can put ServoStop directly in the gearbox, we can use a smaller brake to generate more braking torque. ServoStop acts as the input to our gearbox, which allows the motor to be removed from the unit without the load/axis moving.”

ServoStop is ideal for automation, machine tool, automotive and aerospace industries or anywhere a person is interfacing with a machine with a vertical axis. “If you lose power, you don’t want that load to drop or have much play in it when the power goes out or something goes wrong,” Mattingly explains. “It’s important to note that it’s part of a redundant braking system.”

Currently, most machines have a gearbox, regular input, motor and a brake, which is what protects the vertical load from stopping. When STOBER began researching the safety ratings of the machine, it found redundant braking to be key. “In terms of safety, what if something goes wrong with the motor brake?” Mattingly asks. “ServoStop and the redundant motor holding brake take equal responsibility in holding the load, while the ServoStop can be used dynamically when a quick E-stop is needed.”

STOBER is one of the first companies to integrate the brake into the gearbox in partnership with Rockwell Automation, a global leader in industrial automation. “We hope it to be a game changer,” Mattingly notes. “This is not an industry standard yet. Safety concerns a lot of people and although there is currently no industry demand for it to become a safety standard, it’s on its way. The holding brake is big in Europe and by sticking to their standards, we can grow and remain on the forefront.”

ServoStop is selling nationwide and allowing manufacturers to stay ahead of the game when it comes to safety. The quickest ServoStop STOBER produces has a trigger time of 0.055 seconds. “It’s more of a when not if it will happen,” Mattingly notes. “It is common in the industry to use a servo motor and the permanent magnet brake on the motor in order to stop the machine. While this is fine, it is when an E-stop occurs that motor brake is engaged to stop the machine. The permanent magnet brakes are not designed for this. It will work for a certain number of times, but eventually that brake won’t work at all anymore and that reduces reliability of the machine and becomes a safety hazard to not be able to stop everything in a quick amount of time.”

STOBER is investing heavily in its manufacturing plant in Maysville to increase capacity and improve lead times. The company is adding manpower and updating its machines as it prepares for increased demand. “Our goal with ServoStop is to increase safety throughout the industry,” Mattingly says. “We value our people’s safety and want everyone to value their people’s safety, and ServoStop will allow you to do that. We are investing heavily in ServoStop to provide our customers with safer environments, and reduce the number of injuries and machine downtime.”