Take a closer look at Lightpath Technologies’ visionary optics innovations

Since its inception in 1985, Lightpath Technologies Ltd (Lightpath) has been a renowned leader in optics and photonics solutions, catering to blue-chip customers across sectors such as industrial, defense, telecommunications, testing and measurement, and medical. With expertise in designing, manufacturing, and distributing a wide range of optical and infrared components, including molded glass aspheric lenses, infrared lenses, thermal imaging assemblies, fused fiber collimators, and the revolutionary Black Diamond chalcogenide-based glass lenses, Lightpath has remained at the forefront of innovation. The company’s unwavering commitment to excellence and cutting-edge technology has solidified its position as a trusted provider of advanced optical solutions, driving progress in the field. Sam Rubin, President and CEO, retraces the company’s journey.

“Lightpath has been in the field of optics and photonics for nearly 35 years. Over the years, it underwent various changes, particularly between the 1990s and 2000s, but consistently focused on optical components such as isolators and lenses. For many years, Lightpath was the market leader in precision molded glass lenses, a technology we developed from scratch. In the last four years, since myself and others have joined the company, we have been transitioning Lightpath from a pure component manufacturer to more of a solutions and system provider. This shift is driven by changes in the industry and the maturing of technology. In the past, Lightpath produced lenses sold to other optics companies because such systems were difficult to design, especially considering the small size of the industry back then. But, as the technology becomes more widespread and used in multiple applications and industries, the supply chain structure is evolving and needs to continue to do so. Not every customer is an optics expert with a PhD and the required equipment, thus creating an opportunity for Lightpath to provide value-added solutions. Historically, the company transitioned from making lenses for tens of dollars to subassemblies for hundreds of dollars, and now to cameras worth thousands of dollars. Therefore, this shift represents a drastic change in our business model,” he begins.

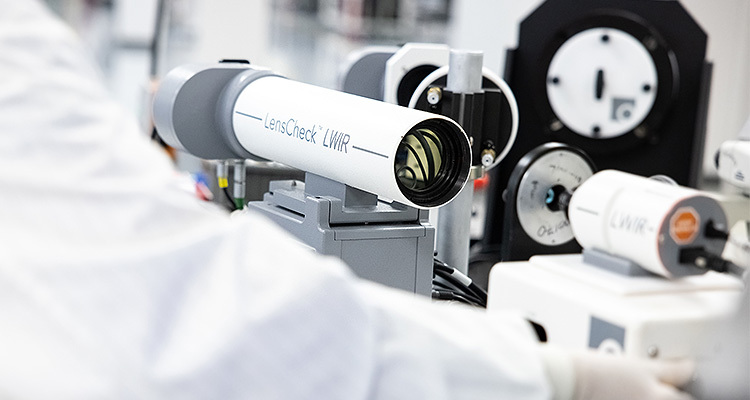

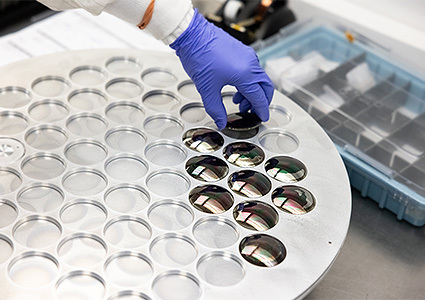

A leading innovator in the industry, Lightpath puts significant effort into the ground-breaking solutions it provides. “When developing our strategy for creating solutions, like any company, we needed to understand the value we provide. We didn’t reflect merely on what we wanted to sell, but rather on why anyone would buy from us – and the key reason is always value. For us, it meant focusing on the few core technologies that allow us to develop solutions better than our  customer base could develop themselves or find elsewhere in the market. Thus, we identified infrared imaging as the best starting point. Within this field, we have a few technologies that play key roles in enabling and differentiating our solutions, empowering us to develop the best infrared imaging systems available. These technologies range from vertically integrated processes, such as making our own glass and very unique types of materials, to advanced lens fabrication techniques. Additionally, we possess tremendous capabilities and expertise in design, including the development of video engines and complete subsystems,” he explains.

customer base could develop themselves or find elsewhere in the market. Thus, we identified infrared imaging as the best starting point. Within this field, we have a few technologies that play key roles in enabling and differentiating our solutions, empowering us to develop the best infrared imaging systems available. These technologies range from vertically integrated processes, such as making our own glass and very unique types of materials, to advanced lens fabrication techniques. Additionally, we possess tremendous capabilities and expertise in design, including the development of video engines and complete subsystems,” he explains.

Sam reveals that throughout Lightpath’s rich history, the company has learned to strike a balance between embracing innovation and ensuring that its efforts align with its strategic direction. Peter Greif, Vice President of Global Operations, tells us more on the subject. “What I would add is that development is fundamentally rooted in Lightpath’s core expertise regarding specific materials, applications, and processes. This expertise enables the next level of development, whether it’s utilizing our existing processes to expand the application of lenses or enhancing manufacturing capabilities. Hence, our innovation process builds upon this foundational expertise, flowing into molding and our proficiency in infrared glass. We then leverage these tools to create solutions, rather than mere assemblies which I think are somewhat elementary. Lightpath strives to be more than just an assembly house or contract manufacturer; we are a comprehensive solutions provider. Although assemblies may be part of what we provide, it’s the overarching solutions we offer that define our role in the market,” Peter highlights.

In the coming weeks, Lightpath will introduce new materials as an alternative to using germanium to address the supply chain challenges caused by limitations on export of the material from China. “Typically, when introducing new materials, there is a lengthy adoption curve driven by factors such as people’s confidence in the proposed material or technology. Glass materials have often faced challenges in manufacturing such as the ability to produce in volume, consistency and repeatability, which can lead to negative reputations if the product varies too much from batch to batch. To address this challenge, we partnered with the Defense Logistics Agency (DLA), responsible for ensuring the continuity of strategic materials for the US defense industry. Together, we outlined an extensive qualification program that the DLA endorsed and sponsored financially. This program accelerates the adoption curve I mentioned earlier by conducting measurements on hundreds of samples from multiple production batches, providing comprehensive statistical data on repeatability, consistency, and more. Thanks to this program, we effectively meet the manufacturing readiness levels (MRL) standards set by the Department of Defense, showing people in the industry that our new materials are ready for manufacturing,” he elaborates.

By pioneering solutions-driven innovation, Lightpath is well-positioned to tackle any future challenges head-on. ■