Teescraft Group

Reliability and experience guaranteed

With their uncompromising focus on cost, quality, delivery, and flexibility, Teescraft Group’s engineers operate at the forefront of precision engineering

For Teescraft Group (Teescraft) – a UK-based, Tier One supplier to several industries – 2021 has been a significant year, in that it has marked the 40th anniversary of its creation, back in 1981. Ever since its earliest days, Teescraft has built up an enviable reputation for producing precision components for power related applications, and today it offers invaluable and reliable engineering solutions to enable its customers’ production runs as smoothly as possible.

Since 2003, Teescraft has been owned by one Robert Yorke, who himself first joined the business in 1987 as an apprentice and now also holds the title of Managing Director. In the corresponding years since Robert took control, the company has undergone a major transformational  program, which has contributed to the generation of year-on-year growth for the past 18 years. In that time, key milestones have included the acquisitions of The Stockton Casting Company in 2011, Steel Pro Services in 2012 (giving it a dedicated fabrication division), aluminium castings producer Westland Castings in 2016, LH Quarry Plant Ltd in 2017, the metals division of Utex Industries (Arefco Special Products Ltd) in 2018, Teescraft Rubber Products in 2019, and Bonds Precision Foundry in 2020.

program, which has contributed to the generation of year-on-year growth for the past 18 years. In that time, key milestones have included the acquisitions of The Stockton Casting Company in 2011, Steel Pro Services in 2012 (giving it a dedicated fabrication division), aluminium castings producer Westland Castings in 2016, LH Quarry Plant Ltd in 2017, the metals division of Utex Industries (Arefco Special Products Ltd) in 2018, Teescraft Rubber Products in 2019, and Bonds Precision Foundry in 2020.

“Through a combination of significant investment in the latest state-of-the-art machinery, as well as in its people, Teescraft has transformed from a prototype part supplier to a Tier One company that is able to meet any challenge it is set in the complex machining and casting sector,” Robert states.

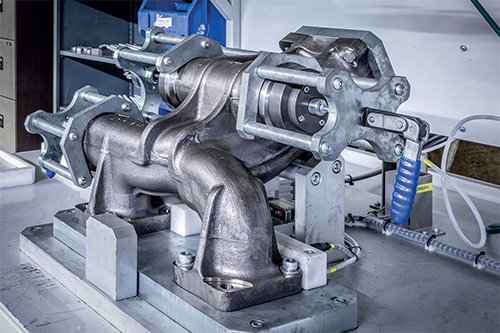

Covering a range of sectors, Teescraft’s expertise has been gained in the automotive, transmission, agricultural, and oil related industries. Working to the highest levels of quality, it supplies products that meet the most exacting of standards to customers throughout the world. At present, the company machines over 300 different parts, including alternator brackets, exhaust manifolds, hydraulic pump adaptors, and fan pulleys, with sizes varying from 0.5KG to 60KG.

“Teescraft is proud to offer a complete range of casting options from grey cast iron through to aluminum and cast steel products,” Robert continues. “With three foundry sites in the UK, our range in terms of volume flexes from very low volumes (one offs) through to an annualized number in the 20,000-to-40,000 range. The same applies to our machinery division. With four sites across the northeast of England, we can offer a full range of support, in terms of size and complexity, and we can machine parts from 0.5KG to 35T.

“Recently, we have supported some new project introductions within the off-highway sector, and through a strong manufacturing approach we have now developed our projected management system and new product introduction program that enables us to meet any challenge.”

Across all of its sites, one can see first-hand the considerable investment that Teescraft has put back into the business to support its growth. This has included the introduction of new 3, 4 and 5-axis machines, along with the latest measuring equipment. This means that the business can now manufacture and measure to the tightest micron tolerance, while retaining complete confidence in its processes.

“In the past five-to-seven years alone, we have invested well over £5 million into Teescraft and its operations,” Robert reveals. “Through the acquisition of companies that complement our supply strategy, be that in machining, casting or rubber to metal manufacture, we have been able to increase our offer to our customers, and hence generate an impressive portfolio and solidify our preferred supplier status.

“With a strong determination to succeed, it is through our process capability that we have invested in people, technology and have developed a world class approach to resolving any manufacturing challenge. Furthermore, it is our focus on providing a strong engineered solution, robust manufacturing process, and with an attention to detail, that sets us apart from our competitors. Put quite simple it’s our team that don’t like to be beaten in anyway, either technical or commercially.”

Clearly a strong-minded business with numerous objectives, Teescraft’s single most valued asset is its people. “By matching our experienced team with young and developing engineers we have supported our collective growth,” Robert explains. “We have introduced students coming from the region’s first and only UTC (university technical college) specializing in advanced manufacturing to help bolster our engineering resource and generate a strong culture of can-do attitude. Each business needs to be maintained through its own performance and management team; however, the underlying drive is to ensure the culture in each of our businesses remains consistent and that the management team makes sure that the main objectives are achieved.”

It is at this point where Robert also draws attention to the strength of Teescraft’s relationships with its suppliers, and how this has benefited all parties. “We treat our suppliers in no different way to our customers, and we fully appreciate that without the support of our supply base we would not be in such a strong position today,” he enthuses. “We ensure they have all the latest information, and we communicate and support them in every step of the process. They are a fully integrated part of our system and understand the business and personal needs we set.”

As the end of 2021 fast approaches, it seems as good of a time as any to reflect back on Teescraft’s accomplishments in terms of overcoming the challenging period that has been the months since Covid-19 emerged, before turning our attention to what the coming years have in store. “When it comes to operating during the midst of a global pandemic, clearly keeping everyone safe was our first and utmost priority, particularly in light of the fact that our industry is one that needs to be active on site, and therefore working from home was not an option for much of our workforce,” Robert notes. “Some support functions did operate remotely but that was limited.

“We adopted our check policies and ensured all employees were working with the maximum amount of distance between them so as not to endanger individuals. We also minimized the number of people entering the site, and ensured all of our plant and equipment was cleaned down regularly. With the support of our team, we have seen very little impact to our day-to-day supply and that’s testament to everyone working together to help deliver our product.”

Moving forward, Robert foresees continued growth for Teescraft, with the business gaining more traction with its current clients, while at the same time expanding into different sectors. “There is a lot to go at, and by having a clear vision and delivery plan, we see our strategy for success becoming a reality. We simply want to be the best supplier in the UK in our sector,” he concludes.

Teescraft Group

www.teescraft.co.uk

Services: Precision engineering solutions provider