The Metals HUB: A Model for Manufacturing Modernization

With a focus on modern technology, workforce development, and collaborative growth, the Metals HUB is a beacon for the future of American manufacturing—a model ripe for emulation nationwide. The Metals HUB program serves as the central objective in the SDA’s mission to revive manufacturing in Chicago’s South Suburbs.

The initiative supports metals, machinery, and equipment (MM&E) companies through transformative strategies, including technical assistance and connecting businesses to new markets. Among its standout features is the Metals HUB Sensor Kit, a tool developed with insights from MxD, the Department of Defense’s National Center for Cybersecurity in Manufacturing. The transition to digital manufacturing will provide real-time data insights, enhancing efficiency, and reducing production bottlenecks.

Workforce development and the aging labor pool

One of the most pressing challenges in the South Suburbs’ manufacturing revival is an aging workforce. Across the sector, seasoned professionals are retiring faster than replacements can be trained, threatening the region’s industrial sustainability.

The Metals HUB program is proactively addressing this issue through partnerships with educational institutions and workforce initiatives. A key highlight is a Department of Energy-funded internship program that prepares young talent for manufacturing careers.

Additionally, the HUB facilitates workshops and upskilling programs tailored to industry demands. These efforts not only attract fresh talent but also reskill current workers, enabling them to operate modern technologies and adapt to evolving job roles.

Integrating robotics and digital technologies

Modern manufacturing thrives on innovation, and robotics is at the forefront of this transformation in the South Suburbs. The Metals HUB equips MM&E firms with strategies and tools to incorporate automation, boosting productivity and precision in operations.

MxD, a key partner of the HUB, plays a pivotal role by offering expertise in digital manufacturing and cybersecurity. Its resources ensure manufacturers can adopt cutting-edge technologies while safeguarding sensitive data—an increasingly critical concern in a digitalized landscape.

The impact of robotics and digital integration extends beyond individual firms. By modernizing the supply chain, these advancements stimulate the regional economy, creating opportunities for related businesses and services. In many ways, the South Suburbs serve as a living laboratory, demonstrating how technology can rejuvenate traditional industries.

Large-scale investments in the region

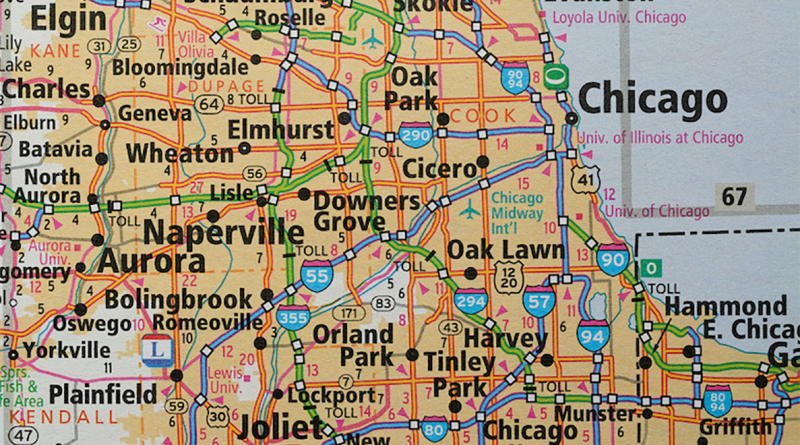

The manufacturing revival in Chicago’s South Suburbs is bolstered by significant investments from corporate giants. Amazon’s choice to establish two robotic fulfillment centers in Matteson and Markham, Illinois, stands as a prime example. These state-of-the-art facilities, each spanning 855,000 square feet, represent the forefront of automation in logistics.

Announced in 2020, these centers have created over 2,000 jobs, transforming the region. Equipped with advanced robotics, they showcase how technology can optimize operations and stimulate economic growth. The presence of large-scale operations attracts ancillary businesses, stimulates supply chain activity, and fosters a supportive ecosystem for manufacturing.

A blueprint for other regions

The success of the Metals HUB and the broader revival efforts in the Chicago South Suburbs offer valuable lessons for other industrial regions. First, collaboration is essential. Partnerships with institutions like MxD and federal funding sources provide the resources necessary for substantial change.

Second, workforce development is critical. By investing in education and training, other regions can ensure a sustainable workforce capable of navigating the complexities of modern manufacturing.

Finally, embracing innovation—whether robotics, cybersecurity, or digital manufacturing—is crucial for competitiveness in a global market. The South Suburbs’ proactive approach serves as a model for deindustrialized areas striving to reinvent themselves.

The transformation underway in Chicago’s South Suburbs is a testament to the power of vision and innovation. Through the Metals HUB, the Southland Development Authority has addressed immediate challenges while laying the groundwork for long-term industrial growth. With a focus on modernization, workforce development, and strategic investments, the region has become a model for revitalizing American manufacturing.

Sources:

- The Robot Report

- Southland Development Authority

To keep up-to-date with our latest manufacturing news, subscribe to our newsletter today.