Through its relentless pursuit of innovation and quality, The Bradbury Group establishes itself as a global leader in metal processing equipment

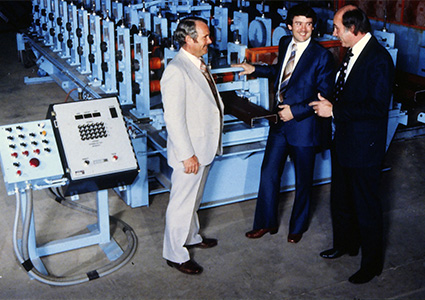

As a world leader in the design and manufacture of high-quality, productivity-enhancing metal processing equipment, The Bradbury Group stands at the forefront of industrial engineering and innovation. The company’s long legacy of success began over 60 years ago, as Chief Executive Officer, David Cox, begins: “Bradbury Group began as Roll Formed Products, Inc. in September 1959. Founded by Floyd Bradbury and his partners, we started as a sales company selling custom roll-formed shapes to the agricultural, recreational vehicle, and aircraft industries. Wichita Roller Die was owned by one of the partners and operated the rollforming equipment. In 1962, Floyd bought the rollforming and machine tool assets of this company. In 1964, we were renamed The Bradbury Co., Inc.

“David Bradbury, the son of Floyd, joined the business full time in 1969, having already been working part-time since 1964. He led our growth into building our own equipment and developing industries and markets outside of our custom rollforming business. This led to growth in equipment for metal buildings, garage doors, grain silos, lighting and HVAC products, steel framing, residential roofing, and coil processing, among many others to both US and international clientele. We then went through a rebrand in the late 1990s and became The Bradbury Group. From there, we developed a global strategy for growth.

“David Bradbury, the son of Floyd, joined the business full time in 1969, having already been working part-time since 1964. He led our growth into building our own equipment and developing industries and markets outside of our custom rollforming business. This led to growth in equipment for metal buildings, garage doors, grain silos, lighting and HVAC products, steel framing, residential roofing, and coil processing, among many others to both US and international clientele. We then went through a rebrand in the late 1990s and became The Bradbury Group. From there, we developed a global strategy for growth.

“Our strategy was to grow our technology and equipment offering to establish our international footprint. This growth created opportunity and I joined the business in 1997 as Operations Manager. Ultimately, our leadership team led the growth of our acquisitions and expansion of our global footprint, now spanning multiple continents and 15 different companies within The Bradbury Group.”

Global growth

The company’s product portfolio has diversified and adapted to industry demands over the past six decades, and now offers a cutting-edge range of goods and services. As David discusses: “We are a global manufacturer of equipment for rollforming, coil processing, and robotic automation. We design and produce automated processing solutions for ferrous and non-ferrous metal processing equipment, as well as composites and non-woven equipment. From coil handling and forming to stacking and packaging, we cover approximately 12 major industrial markets with our equipment offering. These include metal buildings, garage doors, automotive, steel decking and framing construction, bridge and railcar, grain silos and agricultural products, lighting, HVAC, custom rollforming, composite lumber and non-wovens.

“We are vertically integrated and build the entire line sourcing from our own equipment brands. This includes coil handling, presses, hydraulic and mechanical corrective levelers, rollformers, tooling solutions, punch and cutoff dies, flying and rotary shears, slitting equipment, rotary embossers, stacking and packaging equipment, robotics integration, automation and control systems tied to ERP and Calendars for non-woven systems. We also offer a range of related services, including equipment efficiency audits, 24-hour customer service and support, on site operator and maintenance training, and service contracts.”

For over 25 years, David has confidently brought The Bradbury Group into the future. His journey is intertwined with that of the business, as he reveals: “My background is in accounting and construction. I came from the oil and gas industry where I had experience in operations and acquisitions, as well as some financial accounting and management. I started with the business in 1997, as the Operations Manager. After being promoted to General Manager in 2000, I became Chief Operating Officer in 2002, and then President in 2006.

“My focus was to drive global growth and expansion, leading to our acquisitions and startups, which ultimately drove the global growth of The Bradbury Group. We believe the key to successful acquisitions is discernment during the assessment process— finding companies with good management that align with our culture and values regarding how we operate our businesses. Today, my focus is on driving our culture, which we define as our values and beliefs, into the operational DNA of all our group companies. I’m also focused on mentoring and developing the next generation of leaders in the manufacturing business.”

Strategic investment

Under David’s watchful eye, the company has successfully established itself as an international manufacturing powerhouse. “We just recently completed acquisitions in the US and Spain. We also have companies in the US, Canada, United Kingdom, Spain, New Zealand, and Australia. In addition, we have sales offices in Central and South America and Turkey. The recent US acquisition was of Press Room Equipment Company. This company adds press feeding product lines to support a variety of industries, and gives us added manufacturing capacity in the US,” he details.

Staying at the cutting edge of any industry requires strategic investments in the latest tech. The Bradbury Group has successfully adopted a range of innovative new tools in recent years, as David outlines: “We have deployed robots in our manufacturing processes for welding automation and productivity. Additionally, we are continuing to explore the use of robotics in the CNC manufacturing space.

“In our day to day, we utilize multiple 3D printers for research and design validation, as well as 3D printing CNC machining tool holders. We use a variety of 3D simulation software packages for the conceptualization and design of our equipment. We have also recently implemented the use of AI in the sales and marketing process, as well as to automate certain back-office functions. We continue our push to deploy business intelligence software throughout our operations.”

Equipment offering expansion

Rounding off 2024 with a thriving global network, and exciting new ventures on the horizon, the future looks bright for The Bradbury Group. As David concludes: “In 2023, we laid out our vision and strategy for 2028. Our strategic intent is defined as: Focus on Our Core, Expand Our Solutions and Live Our Values. Implementing this strategy will lead to greater automation solutions, and the expansion of our equipment offering.

“What’s more, we hope to develop additional capabilities that we can use throughout our service group to support our customers. The aim here is to reduce our lead times and add manufacturing capacity. If all goes to plan, our growth plans will have us doubling in size again from 2023 to 2028.”