Through strategic acquisitions, Anchor Fabrication is reaching new heights across the US

From idea inception and production engineering to tool design and fabrication, cutting, bending, powder coating and assembly, Anchor Fabrication (Anchor) can meet all light, medium, and heavy metal fabrication requirements. Established in 1990, the business has grown from humble beginnings to its current position, occupying more than 1.25 million square feet of engineering and manufacturing space across nine facilities in the US.

To learn more about Anchor’s evolution, we sit down with Greg Frye, Anchor Partners COO and Anchor Fabrication CEO and President. “Anchor began more than 30 years ago as a single facility in Fort Worth, Texas, headed up by John Willbanks, Jr,” Greg begins. “When his son, Tra, purchased the business from John in 2008, he adopted a broader, more entrepreneurial mindset and had a vision to add facilities and grow the business.

“It’s safe to say that the business has certainly grown; when I joined Anchor in 2014, the turnover was around $40 million, but it has grown impressively to around $265 million in the last six-to-seven years. The Fort Worth facility remains our mothership site, but we’ve added facilities to our portfolio through acquisitions.

$265 million in the last six-to-seven years. The Fort Worth facility remains our mothership site, but we’ve added facilities to our portfolio through acquisitions.

“We acquired ABBY, which is based in Mississippi, around seven years ago, as well as Quality Industries in Nashville, Tennessee, around five years ago. Most recently, we acquired JR Custom Metal Products Inc in Kansas last July, which has rounded out our product offering. Across our four fabrication companies – Anchor Fabrication, ABBY, Quality Industries, and JR Custom Metal Products Inc – we specialize in everything from light gauge cosmetic aluminum through to large, heavy welded assemblies.

“We’ve also grown organically over the years,” he continues. “One of the valuable ways we’ve grown is through cross selling as some of our longstanding customers rationalize their supply chain by using one of our sister companies to meet another area of demand. For instance, one of our light gauge customers didn’t realize we could do steel welding at another of our facilities but now uses us for both requirements. This is just one example of eight or nine partners that are now receiving products from multiple sites.”

Anchor has recently completed a rebranding exercise to consolidate its four fabrication companies – Anchor Fabrication Fort Worth, Anchor Fabrication Mississippi (ABBY), Anchor Fabrication Tennessee (Quality Industries), and Anchor Fabrication Kansas (JR Custom Metal Products Inc) – under the Anchor umbrella. “Although we’ve united the four companies under the Anchor name, each entity still operates as a standalone reporting unit with the necessary resources required to succeed at a local level,” Greg explains.

“Instead of centralizing every process, we’ve implemented a best practice plan to ensure similar systems and a unified approach to operations across the sites. From planning and estimating to engineering and final delivery, we want to maintain as much consistency between the businesses as possible. Rather than creating competition between the sites, we encourage a culture of cooperation and knowledge sharing.

“Across the companies, we cater to a wide variety of markets, including defense, construction, oil and gas, farm and agricultural, ground support equipment, and truck service bodies, doors, and components,” he adds. “By boasting a wide selection of products in such diverse sectors, we can bring a level of stability and reassurance to the business, especially during difficult times and industry disruptions.”

“Across the companies, we cater to a wide variety of markets, including defense, construction, oil and gas, farm and agricultural, ground support equipment, and truck service bodies, doors, and components,” he adds. “By boasting a wide selection of products in such diverse sectors, we can bring a level of stability and reassurance to the business, especially during difficult times and industry disruptions.”

One of Anchor’s latest projects is a long-term agreement for the supply of truck bodies for one of the industry’s leading players. “We were already producing some truck service bodies for a customer in Tennessee, but we were approached by a major client around three years ago and signed a contract in January 2023,” Greg reveals. “Due to the size of the contract, we had to carefully consider how to best structure the business to cope with such volume.

“We leased a 180,000-square-foot facility in Smithville, Tennessee, in May 2023, which was fully capitalized by October, and we began production in December. We’re currently producing more than 100 truck bodies every month, with plans in place to triple our capacity. On an annual basis, we estimate that this truck body revenue alone will boost our overall revenue by more than $80 million.

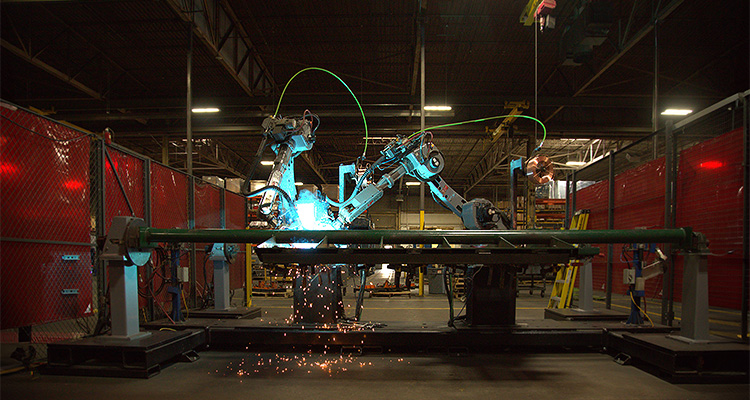

“We’ve also recently invested in cobots,” he informs us. “While we’ve used robotic welders for a long time, we’ve introduced cobots to our operation, which is a mobile robotic welder on wheels. This means we can continuously move the welding unit to the necessary part, as opposed to moving every part to the robot.”

Turning to the future, Greg says: “There are always ongoing discussions about potential acquisitions, but we’re currently focusing on delivering the significant amount of new work we’ve won over the last six months or so, as well as continuing the advancement of our cross selling opportunities and best practices such as cobots. We will continue to invest in our sites and capabilities, and put stable, repeatable processes in place to boost efficiency.

“Over the last five years, we’ve reinvested around seven percent of our profits to set up new factories and add 300,000 square feet of manufacturing space to our portfolio,” he concludes. “We’ve also onboarded a new powder coat system, four new fiber lasers, and six press brakes. As I mentioned earlier, we’re currently at a turnover of around $265 million, but over the next three-to-five years, we’re aiming to grow that figure to around $450 million-to-$500 million.”