Top 10 Additive Manufacturing Companies Shaping the Future

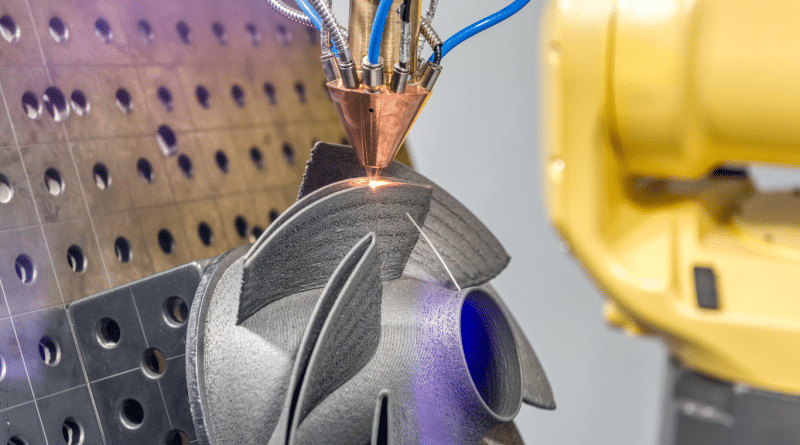

Additive manufacturing (AM), commonly known as 3D printing, has transitioned from a niche prototyping tool to a cornerstone of modern industrial production. As industries seek more efficient, customizable, and sustainable manufacturing methods, AM offers solutions that traditional manufacturing cannot match. This article delves into the top additive manufacturing companies of 2025, highlighting their contributions to this transformative field.

What is Additive Manufacturing?

Additive manufacturing is a process that creates objects by adding material layer by layer, guided by digital 3D models. Unlike subtractive manufacturing, which removes material from a solid block, AM builds structures from the ground up, allowing for complex geometries and reduced material waste.

1. 3D Systems

Founded by Chuck Hull in 1986, 3D Systems is a seminal player in the additive manufacturing landscape. It offers one of the most comprehensive portfolios of 3D printing hardware, software, and materials. The company has successfully transitioned from prototyping solutions to industrial-grade additive manufacturing applications.

3D Systems is deeply entrenched in sectors such as aerospace, automotive, and healthcare, offering customized and regulatory-compliant solutions for implants and dental applications.

- Key Industries: Healthcare, aerospace, automotive

- Notable Technologies: Stereolithography (SLA), selective laser sintering (SLS)

- Recent Developments: Expansion into bioprinting and regenerative medicine applications

2. Stratasys

Stratasys is a trailblazer in polymer-based 3D printing, focusing on the democratization of professional-grade AM solutions. With its patented Fused Deposition Modeling (FDM) and PolyJet technologies, Stratasys provides robust, scalable, and highly accurate manufacturing systems.

Stratasys has made significant inroads into educational institutions and healthcare systems, producing functional prototypes, anatomical models, and surgical guides.

- Key Industries: Education, healthcare, manufacturing

- Notable Technologies: Fused deposition modeling (FDM), PolyJet

- Recent Developments: Introduction of new materials for end-use part production

3. GE Additive

GE Additive is General Electric’s bold bet on the future of metal additive manufacturing. Formed to industrialize AM across GE’s global operations, it quickly became a dominant force in aerospace and medical manufacturing by enabling the production of high-performance, lightweight, and geometrically complex parts.

GE Additive’s strength lies in its control over the full AM ecosystem, from hardware and materials to digital solutions.

- Key Industries: Aerospace, medical

- Notable Technologies: Direct metal laser melting (DMLM), electron beam melting (EBM)

- Recent Developments: Integration of AM components in jet engines and medical implants

4. EOS GmbH

Germany-based EOS GmbH is synonymous with precision and industrial-grade additive manufacturing. Specializing in laser sintering for both metals and polymers, EOS has become a trusted partner for high-reliability sectors like aerospace, automotive, and healthcare.

EOS is at the forefront of sustainable additive manufacturing. Their machines are optimized for high throughput and minimal waste.

- Key Industries: Aerospace, automotive, medical

- Notable Technologies: Laser sintering for metals and polymers

- Recent Developments: Development of sustainable materials and processes

5. Materialise

Belgium-based Materialise is a unique player with a heavy emphasis on 3D printing software and medical applications. The company’s flagship software, Mimics, is used worldwide for anatomical modeling, surgical planning, and custom implants. It also runs one of the largest 3D printing service bureaus in Europe.

Materialise’s open platform strategy allows it to partner with OEMs, hospitals, and academic institutions.

- Key Industries: Medical, automotive, aerospace

- Notable Technologies: 3D printing software, medical modeling

- Recent Developments: FDA-approved software for surgical planning

6. Desktop Metal

Desktop Metal burst onto the AM scene with a mission to bring metal 3D printing to the desktop and production floor. It offers both office-friendly metal printers for prototyping and high-throughput systems for industrial-scale production.

- Key Industries: Automotive, consumer products, industrial

- Notable Technologies: Bound metal deposition, single-pass jetting

- Recent Developments: Launch of high-speed production systems for metal parts

7. Formlabs

Formlabs revolutionized desktop stereolithography by introducing professional-grade machines at accessible price points. Known for reliability and high print resolution, their printers are ubiquitous in dental labs, jewelry workshops, and engineering firms.

- Key Industries: Dental, jewelry, engineering

- Notable Technologies: Stereolithography (SLA), selective laser sintering (SLS)

- Recent Developments: Expansion into biocompatible materials for medical applications

8. SLM Solutions

SLM Solutions is a heavyweight in selective laser melting (SLM), known for its industrial-grade metal printers capable of producing high-strength, high-complexity parts. Their systems are favored by aerospace and automotive OEMs for lightweight component production.

- Key Industries: Aerospace, automotive, energy

- Notable Technologies: Multi-laser systems for metal AM

- Recent Developments: Collaboration with aerospace firms for lightweight component manufacturing

9. HP Inc.

HP’s entry into 3D printing with Multi Jet Fusion (MJF) marked a significant shift toward scalable and fast polymer part production. HP positions itself as a bridge between prototyping and full-scale digital manufacturing.

- Key Industries: Automotive, healthcare, consumer goods

- Notable Technologies: Multi Jet Fusion (MJF)

- Recent Developments: Development of full-color 3D printing and expansion into metal AM

10. Carbon

Carbon has redefined AM speed and material properties with its proprietary Digital Light Synthesis (DLS) technology. Known for partnerships with Adidas and Ford, Carbon’s platform is designed for mass customization and durable end-use parts.

- Key Industries: Footwear, dental, automotive

- Notable Technologies: Digital Light Synthesis (DLS)

- Recent Developments: Partnerships with major brands for mass customization

The additive manufacturing landscape in 2025 is marked by rapid innovation and diversification. Companies are pushing the boundaries of what’s possible, from printing complex metal parts for aerospace to creating biocompatible implants for healthcare. As the technology continues to mature, its integration into various industries is set to deepen, promising a future where manufacturing is more efficient, customizable, and sustainable.