UK-based medical supply manufacturer, Drive DeVilbiss, offers innovative solutions for independent living

As one of the world’s leading manufacturers and designers of durable medical devices, Drive DeVilbiss Healthcare Ltd (Drive DeVilbiss) succeeds in enhancing quality of life for thousands of vulnerable people each and every day. The company has seen consistent growth since its genesis in 2007, as Group Managing Director, Richard McGleenan, outlines: “Drive DeVilbiss was formed 16 years ago, via an acquisition of Medicare Technology Ltd. It was initially an importer of medical products, mainly mobility aids and accessories, operating in the private sale, age care market. Over several years, the business grew both organically and through strategic acquisitions, and we now serve a wide range of healthcare sectors.

“In recent years, we have also expanded into service provision with a sizeable UK manufacturing footprint. In 2017, the global business was acquired by US-based private equity company CD&R. Under new ownership, the business immediately acquired Sidhil Ltd, a manufacturer of medical beds based in West Yorkshire. Since the acquisition, our focus has been on organic growth and efficiency improvements with revenues of £120m in the UK and around $1 billion globally.”

“In recent years, we have also expanded into service provision with a sizeable UK manufacturing footprint. In 2017, the global business was acquired by US-based private equity company CD&R. Under new ownership, the business immediately acquired Sidhil Ltd, a manufacturer of medical beds based in West Yorkshire. Since the acquisition, our focus has been on organic growth and efficiency improvements with revenues of £120m in the UK and around $1 billion globally.”

With nearly two decades’ worth of experience in the medical and long-term care sectors, Drive DeVilbiss provides a range of industry-leading products, expertly designed to support mobility and facilitate independent living. As Richard reveals: “The business operates in several product areas. Our mobility aids range encompasses scooters, wheelchairs, and walking aids. These are sold to retail and government markets, geared primarily toward the age care sector. Our medical product portfolio also includes bathing and toileting products, as well as respiratory products such as oxygen concentrators, conservers, and suction devices.

“As the business has evolved, we’ve added new product categories to our offering. Drive DeVilbiss provides electric profiling beds to hospitals and social care facilities. In the same vein, we offer postural seating solutions for disabled children and adults via Specialized Orthotic Services (SOS), which are primarily sold to the NHS wheelchair services and community rehabilitation markets. We also have a service division providing decontamination, repair facilities, and field servicing available for hospital, home care, and long-term care customers.”

In the competitive healthcare market, Drive DeVilbiss stands out from the crowd. “There is no other company in the healthcare market that is as well spread as us in terms of the markets we serve, the products we offer, and the services we provide. Drive DeVilbiss also offers a unique blend of UK manufacturing, importation, and service provision that ensures the business is agile and capable of responding quickly to market changes. If the last few years have taught us anything, with the pandemic, supply chain issues, and the various global conflicts, it’s that you never know what is around the corner.

“It is important that we are very connected to our customers to make sure that we keep the product ranges fresh and in demand. We need to react to any macroeconomic fluctuations that can otherwise provide an advantage to our competition. For example, the very low container freight costs in 2023 meant that we needed to invest in UK manufacturing to keep the business efficient and competitive,” Richard affirms.

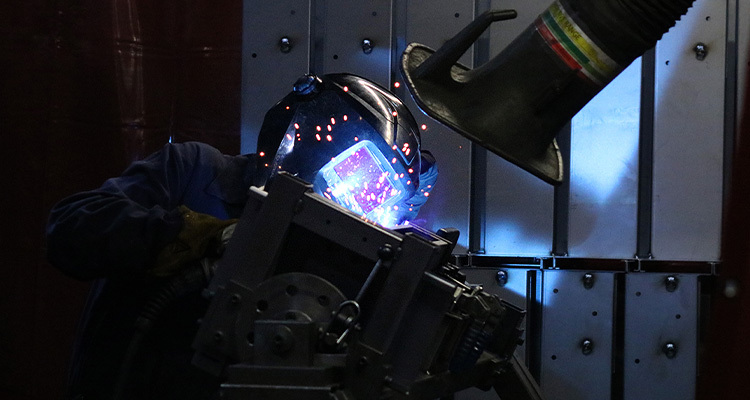

The company’s fully integrated, in-house manufacturing process ensures consistently high quality, reliable production. “We see UK manufacturing as one of our unique selling points, which is why taking a strategic view is critical. The UK excels in engineering and innovation across many sectors and medical equipment is one of them. All the operational departments rely on each other as stakeholders in delivering a world-class product. A full team building program, through practical workshops at senior management level, has galvanized the team, set high standards, and solidified the values and behaviors which will drive operational excellence. I’m very proud of the guiding principles and inspirational leadership we’ve managed to cultivate.

“Tactical projects such as consignment stocking models, Kanban systems, and data collection have smoothed out the manufacturing process, allowing non-value add activity to be identified and tackled accordingly by the new manufacturing engineering department. Improved communication to the workforce around the long-term manufacturing strategy, ongoing capital investments, and a new, streamlined structure make it a very exciting time to be working for Drive DeVilbiss,” details Richard.

“Tactical projects such as consignment stocking models, Kanban systems, and data collection have smoothed out the manufacturing process, allowing non-value add activity to be identified and tackled accordingly by the new manufacturing engineering department. Improved communication to the workforce around the long-term manufacturing strategy, ongoing capital investments, and a new, streamlined structure make it a very exciting time to be working for Drive DeVilbiss,” details Richard.

Not only is Drive DeVilbiss’ manufacturing process strategically streamlined, it’s also sustainable. As Richard reveals: “With widespread operations such as ours, it is important to remain informed of shared best practice. This is ensured through our internal Green Team, a group of staff from all areas of the business whose aim is to ensure we identify best practice and implement it effectively in ways that match operations in that area.

“For example, in our UK manufacturing facilities the focus is on embracing green energy, where we utilize 100 percent renewable energy sources. We also design and manufacture our products in line with a circular economy, which includes efficient use of raw materials, and the re-use and recycling of components.

“As part of our Environmental and Social Governance (ESG) plan we look to embed future sustainability further by minimizing the impact of packaging and upstream logistics. Where products are supplied via our extended, worldwide supply chain, we carefully select and audit suppliers against our ISO14001 and SA8000 processes. As recently as January 2024, we were audited by the UK Environmental Agency, who have also confirmed their approval of our waste stream management as considerate and ethical.”

With change on the horizon, Richard ruminates on what’s next for Drive DeVilbiss: “We are private equity owned and coming toward the end of their investment cycle. In the relatively near future, we will have a new owner and I’m sure, one who has an appetite for investment. Whilst there has been a lot of consolidation in the healthcare market over recent years, it is still relatively fragmented, and there are opportunities to acquire businesses that will take us in different directions from a product technology perspective, as well as providing a pathway for future organic growth. There are also opportunities to vertically integrate with some investment which will help us become more competitive and deliver an even better level of service to our customers. We are here to improve the quality of people’s lives through innovative healthcare solutions; the more we grow means we can help improve more lives than we do now, and that’s always going to be our focus globally.”