Unveiling Don and Low’s rich history of manufacturing cutting-edge textile solutions

UK-based and internationally renowned manufacturer Don and Low Ltd (D&L) enjoys an outstanding reputation for quality, the adoption of new technology and excellent customer service. D&L specializes in manufacturing innovative woven and nonwoven technical textiles such as floorcoverings, geotextiles, synthetic turf, construction, coated fabrics, and medical products, which are used throughout many industries. By focusing on producing high performance and cost-effective material solutions, the company strives to meet and exceed its clients’ demands. As a result, D&L is one of the most versatile manufacturers serving global markets. Today, D&L is part of the multinational Thrace Group, further expanding its profile across the globe. Colin Johnson, Managing Director, delves into the company’s history.

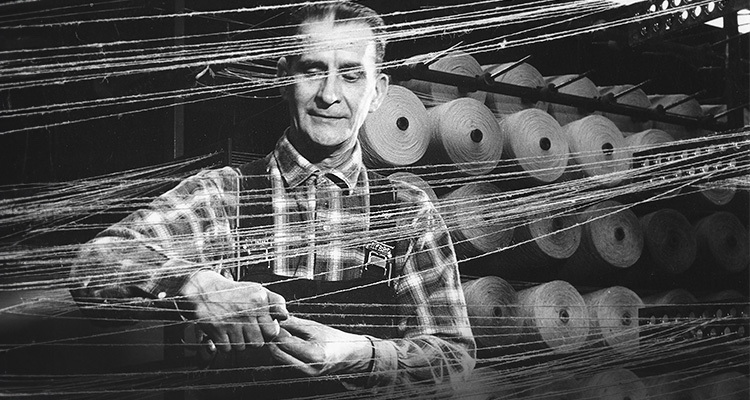

“Originally founded in 1792, D&L has a rich history marked by a legacy of innovation, resilience, and dedication to excellence. The company began as a small woven textiles manufacturer in Scotland, gradually expanding its operations and diversifying its production capabilities and technologies over the years. Through strategic investments in technology and a relentless pursuit of quality, D&L has evolved into a leading, vertically integrated manufacturer specializing in the production of construction membranes, geotextiles, industrial textiles, and yarns. Our journey has been shaped by our unwavering commitment to adaptability and innovation, enabling us to stay ahead of industry trends and meet the ever-evolving needs of our customers, always in a sustainable manner. Today, D&L stands as a trusted name synonymous with quality, reliability, and innovation, poised to continue our legacy of excellence well into the future,” he begins.

textiles manufacturer in Scotland, gradually expanding its operations and diversifying its production capabilities and technologies over the years. Through strategic investments in technology and a relentless pursuit of quality, D&L has evolved into a leading, vertically integrated manufacturer specializing in the production of construction membranes, geotextiles, industrial textiles, and yarns. Our journey has been shaped by our unwavering commitment to adaptability and innovation, enabling us to stay ahead of industry trends and meet the ever-evolving needs of our customers, always in a sustainable manner. Today, D&L stands as a trusted name synonymous with quality, reliability, and innovation, poised to continue our legacy of excellence well into the future,” he begins.

Building on its reputation and unparalleled expertise, D&L has honed its competitive edge to stand out from competitors. “What sets us apart is our status as a vertically integrated manufacturer based in the UK. As such, every stage of our production process, from feedstocks to finished products, is meticulously controlled, and carried out in-house. This level of integration enables us to uphold the highest standards of quality, consistency, and sustainability throughout our operations. Furthermore, our authenticity shines through in our approach to product development. D&L is committed to tackling industry challenges and meeting evolving demands head-on, resulting in innovative and cost-effective solutions tailored to the unique needs of each customer. Consequently, I believe that our proactive approach to production and originality in product development are key factors that distinguish us from other businesses in the sector,” Colin enlightens.

D&L’s proactive approach to manufacturing solutions is translated into its diverse product and services portfolio. “At D&L, we take great pride in offering a varied range of high-quality products and services tailored to meet different needs. Our flagship construction membrane, Roofshield, stands as a testament to our dedication to excellence. With over 25 years of proven performance in the industry, Roofshield is a leading air-permeable pitched roofing underlay specifically designed to facilitate the passage of moisture, thereby eliminating the need for roof ventilation. In addition to Roofshield, we deliver a comprehensive line-up of membranes made for brick and block, timber frame and steel frame applications. Each product is crafted with innovation to deliver unmatched performance and reliability. Whether it is membranes for roofing, walling, or flooring, our goods are backed by decades of expertise and the steadfast dedication to quality we are famous for,” he adds.

Always striving to enhance its efficiencies, D&L is investing significantly in incorporating technology within its manufacturing processes. “Technology plays a pivotal role in enhancing our production capabilities here at D&L. We have made sizeable investments in technological advancements to streamline our operations, boost overall productivity and drive product quality. One specific area where technology has made a considerable impact is in our manufacturing processes. We utilize state-of-the-art production lines, fault detection systems and Industry 4.0 technologies to optimize production efficiency, reduce waste, and ensure consistent product quality standards. With in-house recycling, we see construction as a pivotal industry for driving sustainability efforts, aligning with our commitment to environmental stewardship. Additionally, we leverage advanced software solutions for inventory management, order processing, and logistics, empowering us to shorten lead times and meet customer demands more swiftly. By embracing technology across our operations, we not only achieve greater efficiency but also enhance our agility and competitiveness in the market,” highlights Colin.

Always striving to enhance its efficiencies, D&L is investing significantly in incorporating technology within its manufacturing processes. “Technology plays a pivotal role in enhancing our production capabilities here at D&L. We have made sizeable investments in technological advancements to streamline our operations, boost overall productivity and drive product quality. One specific area where technology has made a considerable impact is in our manufacturing processes. We utilize state-of-the-art production lines, fault detection systems and Industry 4.0 technologies to optimize production efficiency, reduce waste, and ensure consistent product quality standards. With in-house recycling, we see construction as a pivotal industry for driving sustainability efforts, aligning with our commitment to environmental stewardship. Additionally, we leverage advanced software solutions for inventory management, order processing, and logistics, empowering us to shorten lead times and meet customer demands more swiftly. By embracing technology across our operations, we not only achieve greater efficiency but also enhance our agility and competitiveness in the market,” highlights Colin.

Looking to the future, Colin shares what should be expected from D&L for the year ahead and his vision for the company’s long-term trajectory. “In 2024, D&L will still uphold its longstanding commitment to innovation while honoring its rich tradition dating back to 1792. Building on our legacy of excellence, we will continue to push the boundaries of innovation, unveiling products and solutions tailored to meet the evolving needs of our customers and the industry itself. Our focus will remain on delivering quality, authenticity, and sustainability across all aspects of our operations, thus ensuring our products and services pave the way toward a brighter, more innovative future. As for the longer-term future, we envision D&L emerging at the forefront of the construction and geotextile industry within five years’ time. We aspire to lead the way in innovative solutions, exemplified by Roofshield, while further solidifying our position as a pioneer in sustainable manufacturing practices. Moreover, D&L aims to expand its global reach, positioning itself as the go-to choice for contractors seeking reliable, sustainable, and cutting-edge products. Our commitment to excellence, coupled with our dedication to sustainability, will continue to drive our growth and shape the future landscape of the construction and geotextile industries alike,” he concludes.

Through vertical integration and a strong focus on technology, D&L remains committed to driving continued innovation in engineered solutions.