Unveiling the innovation and ambition driving Syntec Optics’ future direction

Specializing in custom optics and photonics, Syntec Optics Ltd (Syntec) has emerged as one of the largest optical manufacturers in the US. The company’s comprehensive range of services encompasses polymer and glass molding, diamond turning, precision machining, opto-mechanical and electro-optical clean room assembly, and optical coatings, all tailored for a wide range of optics and photonics applications. Syntec has revolutionized the industry by pioneering the manufacturing of optics from polymers, which enables cost and weight reduction while increasing the biocompatibility of the company’s optical systems. Vertically integrated from design to component manufacturing and assembly, Syntec is prepared to meet any program requirements, solidifying its position as a leading global supplier within the defense, bio-medical and consumer end markets. President and CEO, Joe Mohr, shares Syntec’s story.

“Currently headquartered in Rochester, New York, Syntec was established over 20 years ago. Initially, Syntec began as a collective of three small companies dedicated to the optics and photonics space. However, in 2016, these three companies merged into a single location, leading to the expansion of Syntec as a unified, larger company. Following that, Syntec focused on enhancing value for its customers through both vertical and horizontal integration,” he begins.

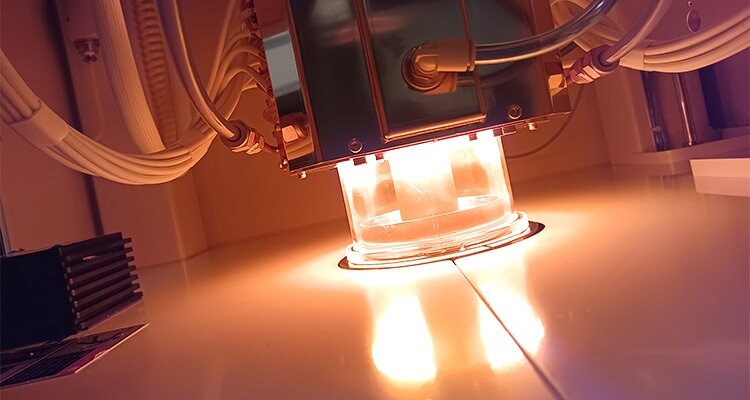

Director of Sales, Sara Hart, elaborates on Syntec’s current product range. “At the front end, we have a comprehensive design and engineering team that empowers us to support our customers with full system designs, as well as designs tailored for manufacturing and engineering. From there, we can provide components to our customers such as diamond-turned optics, molded polymers, and glass optics. Furthermore, we possess an in-house precision machine shop, and strive to offer end-to-end solutions for our clients. Syntec boasts a wide range of capabilities, with on-site optical coating chambers, metrology, environmental testing capabilities, and three cleanrooms, both assembly and molding, which support our operations. These capabilities allow us to perform opto-mechanical and electro-optical sub-assemblies making Syntec a one-stop-shop and allowing our customers the benefits of working with one vendor and avoiding multiple markups from managing multiple suppliers.

“Historically a lot of the work we’ve performed has been custom. I find custom work particularly exciting because every product we make is unique, which is a testament to our versatility. As an adaptable company, Syntec operates within a multitude of markets. Whilst we maintain a relatively even presence across these markets, we are predominantly active within the defense and medical sectors and engage in many commercial projects. All in all, Syntec enjoys a balanced presence amongst the different industries we serve,” she adds.

Joe delves into the scope of Syntec’s work and growth within various industries. “Working within the space sector is quite thrilling as the projects we have undertaken have been challenging but positive experiences. I believe that Syntec is one of the only companies in the US that can and has achieved what we have accomplished. This includes supporting satellites in low Earth orbit. These accomplishments align with our mission and core values, which revolve around changing the lives of people. Regarding our contributions to the medical sector, we are currently witnessing some exciting developments within cancer detection, where we support the optical subsystems essential for enhancing accurate analysis. Another area that is gaining momentum is quantum computing, with the US government recognizing the value of investing in this technology. This acknowledgement has generated more opportunities for us within the sector, as it encourages companies to seek our expertise,” he explains.

Diversifying into numerous markets enables Syntec to manufacture products for a broader customer base, but also requires the company to adapt its processes to enhance efficiency. “Our philosophy on automation is that it should enhance our employees’ abilities, not eliminate the need for them. Instead, automation would be used to streamline and automate processes, allowing our staff to focus on more complex tasks. In addition, this would enable us to provide our workforce with opportunities for career development within the organization. As a result, we have incorporated automation in several projects to handle tasks like replicative molding, injection molding, machining and diamond turning. This decision was driven by factors such as the need to achieve the precise tolerances required for our products, reduce the cost structure for our customers and prioritize our employees’ career development,” highlights Joe.

Diversifying into numerous markets enables Syntec to manufacture products for a broader customer base, but also requires the company to adapt its processes to enhance efficiency. “Our philosophy on automation is that it should enhance our employees’ abilities, not eliminate the need for them. Instead, automation would be used to streamline and automate processes, allowing our staff to focus on more complex tasks. In addition, this would enable us to provide our workforce with opportunities for career development within the organization. As a result, we have incorporated automation in several projects to handle tasks like replicative molding, injection molding, machining and diamond turning. This decision was driven by factors such as the need to achieve the precise tolerances required for our products, reduce the cost structure for our customers and prioritize our employees’ career development,” highlights Joe.

On top of its investments in automation, Syntec has recently acquired several state-of-the-art diamond turning machines. “These machines offer extremely unique capabilities and are essential to our work, but as we all know, the machines are worthless without the talent to operate them. In fact, Syntec has been setting and breaking its own records for the quality of its products using diamond turning machines, but this level of quality is a direct result of our talented team’s efforts,” Joe states.

Within the busy year ahead, Joe expects Syntec to add more acquisitions to its portfolio, among other ambitions. “Though we have achieved record sales in the last couple of years, I believe that investing in further product development to address our customers’ needs will set us up for a new level of growth. Our goals for 2024 won’t be easy, but we trust in our abilities to execute these goals. Moreover, we plan to purchase additional equipment in 2024, that will significantly improve our efficiency. I strongly believe that this year will be a record-breaking year for Syntec,” ends Joe.

By leveraging its talented workforce and cutting-edge technologies, Syntec is well-positioned to boost its industry leadership while achieving new milestones of growth and innovation.