Visual Components launches all-in-one robotic software platform

Visual Components Robotics OLP combines robot programming with existing simulation software to enhance efficiency and robot utilization

Visual Components, the developer of 3D simulation software, has successfully transitioned to a new, more powerful solution. It follows the company’s acquisition of Delfoi Robotics, an industry-leading offline robot programming (OLP) solutions provider, in October 2022.

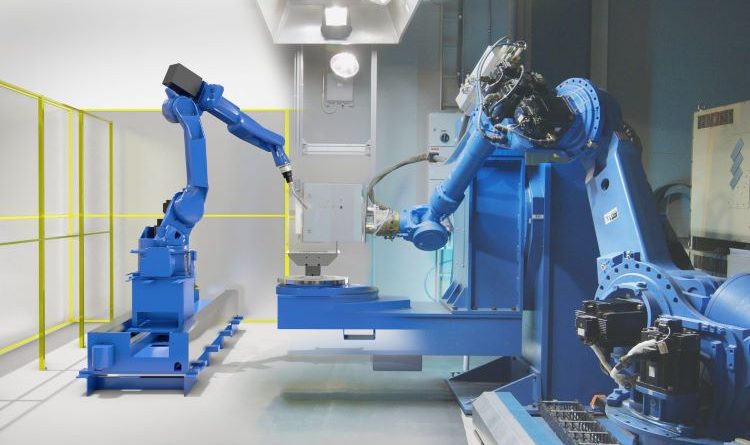

Aimed at both manufacturing simulation and robot offline programming customers, Visual Components Robotics OLP operates via a single software. This enables manufacturers to bring their technology deployments under one banner, improving robot utilization and enhancing production efficiency.

It is tailored to accommodate most industrial deployments and robot brands. Specifically, the platform is compatible with primary robot and cobot brands, including 17 post-processors from companies like KUBA and ABB.

Manufacturers can seamlessly transfer their robot programs from the platform to physical robots on the shop floor. Users will also benefit from reliable and accurate programming capabilities that are ten times faster than manual processes.

Visual Components Robotics OLP has been brought to market at a time when robots are being underutilized in the manufacturing sector. Persistent challenges like labor-intensive processes, complex product mixes, and skills shortages are hindering innovation and delaying progress in digitalization strategies.

This unified solution provides the basis for employees to be trained in multiple disciplines. This encourages upskilling in the Industry 5.0 era, as well as an opportunity to drive technical skills among the new generation entering the sector. Rather than eliminate jobs, technology services to fill skills gaps.

“Put simply, Visual Components Robotics OLP makes digital production transformation possible,” said Mikko Urho, CEO at Visual Components. “It’s more than just a product release; it’s a testament to our understanding of industry challenges and continued commitment to addressing them head-on. We’re bridging the efficiency gaps and streamlining processes to ensure our customers always stay one step ahead.”