Wenzel Downhole Tools hits pay dirt thanks to continuous improvement and a lasting lean manufacturing transformation

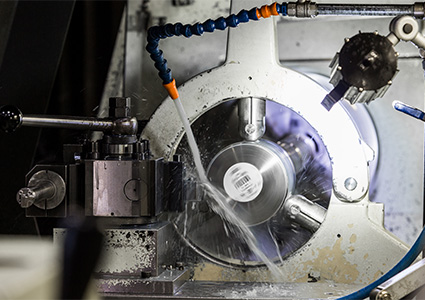

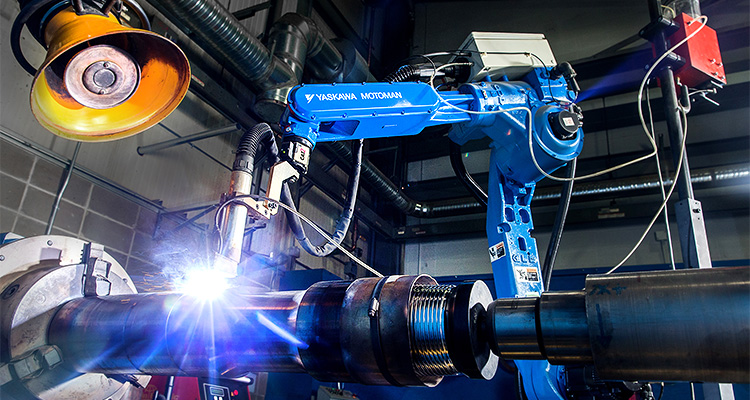

On drilling rigs around the world, Wenzel Downhole Tools (WZL) is recognized and well respected for its premium-quality build, innovative engineering and reliable performance. From its shop in Edmonton, Canada, the company manufactures a wide range of drilling motors, jars, shock and vibe tools, and other drilling implements used to “make hole” for oil and gas, geothermal and utility projects. WZL proudly produces these tools entirely in-house from conceptualization to manufacture. When the tools return for service, they are broken down and thoroughly inspected alongside reports from the field. Necessary maintenance and repair are performed, and the tools are sent back to the field.

By owning the entire product lifecycle of its tools, WZL boasts complete control of its products. With that control, the company can provide customers with a direct line to floor-level support and product innovation – a line that is frequented. The relationship WZL offers its customers is its key differentiator in a fast-paced industry driven by results and dominated by large oil companies. That advantage, however, often comes with some additional manufacturing challenges.

By owning the entire product lifecycle of its tools, WZL boasts complete control of its products. With that control, the company can provide customers with a direct line to floor-level support and product innovation – a line that is frequented. The relationship WZL offers its customers is its key differentiator in a fast-paced industry driven by results and dominated by large oil companies. That advantage, however, often comes with some additional manufacturing challenges.

“Our customers fuel us,” begins Shawn Feguenne, Vice President of Manufacturing. “Their success is our success and, in our industry, innovation breeds success. Those who stand still fall behind. When customers run our tools downhole, they are in constant communication with us. When customers return their tools for service, we get a report on their performance and analyze their condition. With all this information, our teams, from Quality Assurance, Engineering and Manufacturing, tweak and refine. Our products, much like everything else at Wenzel Downhole Tools, are in a continuous state of improvement. Innovation has always been a part of the WZL DNA but, as our business grew, we had to evolve. We needed to find a way to continue innovating and investing in R&D without sacrificing production times and quality.”

Growth & expansion

Incidentally, WZL kicked off its lean manufacturing transformation journey in 2017. The business introduced a process called ‘The Wenzel Way’ – a structured approach to establish standard work practices for employees and implement the ‘5S’ Japanese production line methodology throughout the entire company.

“In the first year of our program, we conducted extensive training sessions with employees to have everyone understand the plan and how it applies to their job,” Shawn continues. “We tried to help them reevaluate the way they work. But change in any organization is never as easy as it seems. We felt like we had a good plan, but after a year of experimentation and conversations with colleagues on the shop floor, we recognized the need for additional external support.”

As a part of the journey, the management team at WZL turned to Moffitt Consulting, a leader in lean transformation, for assistance.

“Moffitt gave us the tools and advice to evaluate current state processes, identify desired results, and uncover and prioritize changes on the path to lean manufacturing,” says Shawn. “Since the start of our collaboration with Moffitt in 2018, we have conducted over 100 internal ‘kaizens’ (change events), in which we identify a problem on the shop floor and convene to brainstorm five possible solutions. We would hammer things out and ultimately come up with a winner.

“The process was collaborative and engaging, often fun. Sometimes, not fun. It can be tough sometimes to break people away from a familiar bond or routine. But we always ensure our decisions are rooted in our values, our mission. It also helps that our entire management team began their Wenzel careers on the shop floor. That in of itself is a remarkable success, and something to be proud of, but having been immersed in every facet of our operations, it is easier for us to

get buy-in on the shop floor. We have first-hand experience in the machine cell, in manufacturing parts. While 100 percent buy-in may not be feasible, we are pleased with the progress of our organizational culture, which has surpassed my expectations.”

Success in culture and operational efficiency has certainly contributed to WZL’s growth and its remarkable geographical expansion; so too has its dedication to customer success. WZL primarily operates within the energy sectors in the Middle East, the United States, Northern Africa, South America, Europe, and Australia. Beyond providing tools, the company provides customer support, exemplified by efforts in Libya where resources to train staff may be limited.

“Clients genuinely value the level of support we provide,” Shawn explains. “Especially considering that many drilling tool companies are reluctant to dispatch their personnel around the world to share trade secrets. We send out service technicians when needed and make sure our customers are getting the most out of our tools. In the early phases of our lean transformation, we established a department named ‘C Support’, our version of customer service. It operates around the clock. In the past, we experienced inefficiencies and waste due to having multiple sales reps and six different accounts… By consolidating our customer service and sales teams, we have achieved a more cohesive and manageable structure. Our small team provides 24-hour support for customers on the other side of the world. C Support has been a key driver of our success.

Continuous improvement

“A significant aspect of lean manufacturing is waste elimination (in terms of time, material, resources, etc.),” Shawn elaborates. “Because of this, we have progressively moved nearly all our equipment to better locations that reduce unnecessary travel around the shop floor and enhance safety and efficiency. Most machinist tools are available at point of use. We have made changes to reduce forklift traffic and empower colleagues to do more with reduced effort. For example, our new NC cell configuration has three NC machines positioned in such a way that only two machinists are required to operate them, and multiple operations can be performed in a choreographed sequence. Lead times are reduced, and machine time is optimized. We did not need to purchase expensive new equipment to gain efficiency here, we just needed to get creative, rearrange some things and communicate with our people.

“Usually, maybe after a week or so, once you see the transformation executed in its true form on the floor, you wonder how you were able to function before the change,” says Shawn. “But the irony is that in a lot of cases, the need for a given transformation was hard for us to realize without external support. I have been at WZL for 19 years and after that much time, you are used to seeing things done a certain way. It can be difficult to imagine an alternative. Moffitt gives us that outside, expert perspective that allows us to take a break from the hectic rush of the everyday and question why we do things the way we do. We continue to rely on their expertise and receive great support from them.”

Shawn and his team will not find relief from the pressure to improve their products or manufacturing processes any time soon. Thanks to WZL’s newly reignited partnership with sister company Basin Precision Machining of Jefferson, Wisconsin, and the uncertainty of a North American trade war looming over the heads of manufacturers and clients alike, 2025 promises to be an interesting year full of opportunity, kaizen and improvement.