What should be driving and motivating your digital transformation journey?

Klaus Schwab, founder of the World Economic Forum, once said: ‘In the new world, it is not the big fish which eats the small fish, it’s the fast fish which eats the slow fish’. This idea resounds deeply with me as we consider digital transformation in manufacturing.

Too often, we focus on implementing new systems without considering the most crucial aspects: our clients and our ability to adapt quickly to their evolving needs. In today’s business world, the companies that thrive are those that can swiftly adjust their operations and services to meet client demands.

Digital transformation is often misinterpreted as rushing to buy an ERP system, CRM system, or managing various software integrations. The focus should be on making life easier for your clients and doing so faster and more effectively than your competitors. But what does this really mean in practice?

It’s about creating seamless experiences, anticipating needs, and delivering value in ways that weren’t possible before, all while maintaining the agility to pivot as client expectations change.

Beyond the jargon

When you hear ‘digital transformation’, what comes to mind? For many, it’s images of robots on factory floors or elaborate software systems. But that’s only part of the picture. True digital transformation means fundamentally changing how we operate and deliver value to our clients.

At A-SAFE, we’ve learned that successful digital transformation starts with understanding our clients’ pain points. It’s not about adopting technology for technology’s sake, but rather solving real problems and creating seamless experiences. This involves implementing digital technologies that allow us to address client challenges more quickly and efficiently. This approach requires a deep understanding of our clients’ businesses, their challenges, and their goals.

The client experience revolution in manufacturing

Manufacturing has traditionally been product-centric, focusing on what we make rather than how we serve. But the game is changing. Clients today expect more than just a quality product; they want exceptional service, transparency, knowledge, and ease of doing business.

Digital tools are changing how we interact with clients. From virtual product demonstrations to online configurators and real-time order tracking, we’re seeing a fundamental change in client expectations. These tools not only improve the buying experience but also foster stronger, more collaborative relationships with our clients.

For instance, we’ve implemented a digital platform that allows clients to visualize our safety solutions in their own environments before purchase. This makes the decision-making process easier for them, reduces the likelihood of errors, and improves overall satisfaction.

Data-driven insights

One of the most powerful aspects of digital transformation is the ability to gather and analyze data to better serve our clients. But it’s not just about collecting data; it’s about turning that data into actionable insights that drive real value for our clients.

By leveraging predictive analytics, we can anticipate client needs before they even arise. For example, based on usage data, we can predict when a client’s safety barriers might need maintenance or replacement, allowing us to proactively reach out and offer solutions. This proactive approach enhances safety and demonstrates our commitment to our clients’ ongoing success.

However, with great data comes great responsibility. We must balance our use of data with respect for client privacy and trust. This involves being transparent about our data practices and ensuring that our use of data always aligns with our clients’ best interests.

Streamlining operations for client benefit

Internal efficiency might seem like an inward-facing goal, but it has a direct impact on client experience. Every inefficiency in our processes ultimately affects our clients, whether through longer lead times, higher costs, or inconsistent quality.

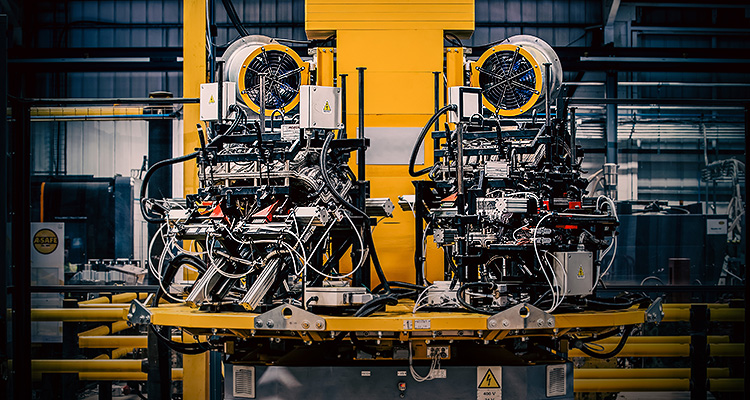

Digital transformation allows us to streamline our operations in meaningful ways. For instance, by implementing IoT sensors in our manufacturing process, we’ve been able to improve quality control and reduce production time, leading to faster deliveries and more consistent products. This also allows us to be more responsive to changing market demands.

Digital transformation allows us to streamline our operations in meaningful ways. For instance, by implementing IoT sensors in our manufacturing process, we’ve been able to improve quality control and reduce production time, leading to faster deliveries and more consistent products. This also allows us to be more responsive to changing market demands.

We must ensure we’re passing the benefits of our improved efficiency forward. The time and resources saved must be put to good use, innovating and enhancing our service. This might involve developing new products, offering more personalized services, or investing in further improvements to our client-facing processes.

Cultivating a client-centric digital culture

Perhaps the most challenging aspect of digital transformation is cultivating a culture that puts clients at the heart of every digital initiative. This isn’t just about training employees to use new tools; it’s about fostering a mindset that constantly considers how to make life easier for our clients.

At A-SAFE, we’ve made this a core part of our digital-transformation journey. Every new digital initiative is evaluated not just on its technical merits, but on how it improves the client experience. We’ve even adjusted our KPIs to reflect this, measuring success not just in terms of efficiency gains or cost savings, but in client satisfaction and ease of doing business.

This cultural change is perhaps the most crucial and challenging aspect of digital transformation. After all, the most sophisticated digital tools are useless if they’re not being used with the client in mind. It requires ongoing commitment, communication, and a willingness to continuously learn and adapt based on client feedback.

My final thoughts

As we continue our digital transformation journey, we mustn’t lose sight of what truly matters. It’s not about having the latest technology or the most intricate systems. The focus should be on using these tools effectively and purposefully.

The future of manufacturing lies not just in what we produce, but in how we serve. By putting our clients at the heart of our digital transformation efforts, we can create experiences that not only meet but exceed expectations. This approach isn’t just beneficial – it’s crucial for long-term success and relevance.

I challenge you, in your next digital-transformation meeting, to consider how your decisions will improve your overall service and operations. The answer to that question should guide every decision we make. It’s not always the easiest path, but it’s undoubtedly the most rewarding.

After all, in the digital age, our most powerful tool isn’t a piece of software or a machine – it’s our commitment to excellence and innovation. By keeping this focus, we can ensure that our digital-transformation efforts truly transform not just our operations, but our entire business approach.

By Andy Rainforth

Andy Rainforth is CCO at A-SAFE, a global leader in workplace safety solutions. As the creator of the world’s first industrial-strength polymer barrier safety system, innovation is at A-SAFE’s core. Supplying transformative safety tech to warehouses, factories, airports, and more, A-SAFE’s impact spans across 65+ countries around the world.