Why Horse Powertrain is driving multiple diverse paths to global Net Zero

Established as a joint venture between Geely and Renault, Horse Powertrain (Horse) was built on a foundation of over 125 years of Internal Combustion Engine (ICE) and hybrid powertrain heritage, including a production footprint, research and development resources, and intellectual property. These initial shareholders were joined by Aramco last year, who acquired ten percent of the company, with Renault and Geely retaining 45 percent shares each.

Horse is a totally independent company that provides universal, brand-agnostic solutions for low-emission and alternative fuel power needs. The company is

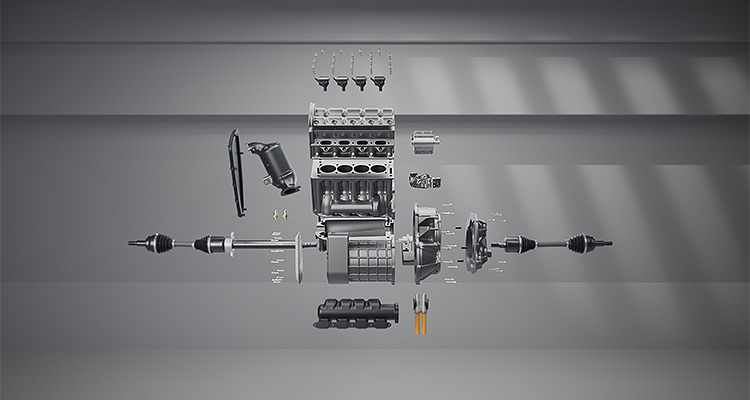

unique in that its largest shareholders, Renault and Geely, are also Horse’s customers. Across its 17 manufacturing plants and five research and development (R&D) centers, Horse designs and produces a broad range of engines, transmissions, and gearboxes, spanning the full hybrid and combustion component stack and covering around 80 percent of global market requirements.

Ingo Scholten, Chief Technology Officer, elaborates on the company’s portfolio and its evolution so far. “Our product range is very diverse, from Power Electronics Boxes (PEB) and hybrid engines to gearboxes and engines compatible with flex fuels,” he opens. “We develop solutions tailored to the specific needs and pressure points of different markets and applications. By doing so, we support a tailored transition to manufacturers’ net-zero goals. While electric vehicles (EVs) play an important role in the journey to Net Zero, they realistically address only about half of the global transportation challenge. Many customers and regions face infrastructure, economic, or operational constraints which highlight the fact that solutions are not one size fits all.

“Last year, we introduced our next-generation range extender powertrains,” Ingo continues. “Extended range EVs (EREVs) are designed to combine the benefits of electric driving with the flexibility of longer range and can work across both EV and combustion-based platforms. These systems give drivers up to 200 kilometers of EV-only range, with an additional 600 kilometers provided by an onboard petrol engine that works purely as a generator. That means you get up to 800 kilometers of total range, without the engine ever directly powering the wheels. Unlike traditional hybrids, this compact setup allows the engine to run only when needed, and always in its most efficient mode, helping to reduce fuel consumption and emissions. The high-voltage battery, about half the size of a full EV battery, keeps weight and costs down while easing demand for critical minerals.”

Range extenders allow for longer range by combining the benefits of electric driving with the extended capabilities of a combustion engine. In Horse’s next-generation system, the vehicle is equipped with a high-voltage battery that delivers up to 200 kilometers of pure electric driving, ideal for daily commutes and access to low-emission zones in urban areas. Once the battery charge is depleted, a compact, efficient engine activates, not to drive the wheels directly, but to act as a generator that produces electricity to maintain the battery’s charge. This engine operates in an optimal rev range, meaning it runs consistently in its most efficient state, reducing fuel consumption and emissions, and the electricity it generates powers the electric motor, which continues to drive the vehicle without interruption.

“This setup adds an additional 600-to-800-kilometer range, allowing the vehicle to cover up to 1000 kilometers,” Ingo elaborates. “In contrast to traditional plug-in hybrid electric vehicles (PHEV), the combustion engine of a range extender never directly drives the vehicle’s wheels. When the battery’s state of charge is sufficient, the engine will automatically be turned off. The vehicle’s battery can also be charged in a similar manner to an EV, using a public charger or domestic power supply. This means drivers get the full experience of an EV without the range anxiety associated with BEVs.

“This setup adds an additional 600-to-800-kilometer range, allowing the vehicle to cover up to 1000 kilometers,” Ingo elaborates. “In contrast to traditional plug-in hybrid electric vehicles (PHEV), the combustion engine of a range extender never directly drives the vehicle’s wheels. When the battery’s state of charge is sufficient, the engine will automatically be turned off. The vehicle’s battery can also be charged in a similar manner to an EV, using a public charger or domestic power supply. This means drivers get the full experience of an EV without the range anxiety associated with BEVs.

“This technology is well-positioned to meet the needs of major markets, as EREVs extend the EV offering currently on the market and allow a virtually identical pure-electric experience to a BEV but allow sizeable reductions in battery capacity,” Ingo shares. “We have already signed some deals in Brazil to provide EREV solutions for passenger vehicles and microbuses, reflecting the demands of the local market. It offers consumers the best of both worlds and marries a fully electric driving experience with the range and reassurance of combustion. Our research has shown that EREVs will support EV adoption and help OEMs amortize their investment in BEV technology.”

Turning to R&D, Ingo shares: “I’m extremely excited and optimistic about our innovation roadmap, and we have a lot in the pipeline. Our focus goes beyond just developing components; we design highly efficient, compact, optimized powertrains that deliver the power our customers need, but with low emissions and at a competitive price. We’re exploring hydrogen, but much of this development depends on investment in capital-intensive projects to produce, store, and distribute hydrogen on a commercial scale.

“On the vehicle front there have also been breakthroughs in fuel technology, such as the rise of flex fuel engines. These innovative engines, capable of running on fuel blends like petrol and ethanol, provide a unique opportunity to reduce transport emissions, running costs and full lifecycle CO2. To accommodate flex fuels, powertrains need to modify engine components like injectors, lines, and pumps, so in recent years, we’ve concentrated on reducing the number of modifications required, allowing flex fuel engines to become significantly cheaper and easier to assemble.”

Speaking about how the sector is moving towards net-zero objectives, Ingo continues: “The industry is revisiting some old assumptions, primarily the idea that ‘one size fits all.’ When the age where ICEs accounted for 100 percent of the market came to an end, many stakeholders assumed that the trajectory of the industry was towards 100 percent of another solution – in Europe for example, it was battery EV adoption. The industry is now realizing that these two extremes don’t reflect the future of powertrains.

“Instead, there will remain niches for every powertrain category to reflect the needs of consumers, markets, and industries, including pure-ICE, hybrids, and BEVs, and automotive brands are having to adjust to this reality. It can also depend on geography; for nations with large rural areas without strong grid infrastructure, hybrid vehicles are a practical and cost-effective solution, whereas in regions with surplus grid power, hydrogen and e-fuels are a great decarbonization solution. Alongside infrastructure, our product range includes combustion engines that run on low-carbon fuels including methanol and ethanol, and we’re very enthusiastic about flex fuels, with the global flex-fuel engine market projected to reach $109 billion by 2030.”

Horse is also developing the Future Hybrid Concept, a groundbreaking powertrain that combines an internal combustion engine, electric motor, and transmission into one compact, fully integrated unit. “The system is lightweight and modular, fitting within current BEV architectures and allowing automakers to respond more dynamically to shifting customer demand,” Ingo elaborates. “Fuel flexibility is another key feature, as the powertrain can run on a variety of fuels from traditional gasoline and ethanol flex fuels to pure methanol and newer synthetic fuels.”

Summarizing his thoughts on the powertrain industry and its net-zero ambitions, Ingo concludes: “What really sets us apart is our ability to go beyond individual components and deliver full powertrain system integration. We’re not just developing engines, transmissions, or electric motors in isolation; we’re optimizing and integrating components into complete, high-performance powertrain systems. At Horse, we believe there is no ‘one-size-fits-all’ approach to powertrain development, and as such, our vision is to offer many different paths to Net Zero, with the scale, expertise and innovation to deliver in every market.”