With continued innovation at its core, Radio Frequency Systems (RFS) remains at the forefront of the communications industry

As a designer and manufacturer of wireless and broadcast cable solutions and accessories, Radio Frequency Systems (RFS) specializes in providing premium, future-ready cable solutions for customers across the globe. Celebrating its 125-year anniversary in 2025, the business has a long heritage in the industry with roots in manufacturing telephone wire, and a reputation for reliable and long service life connectivity systems.

Since its foundation in 1900, RFS has pioneered several breakthroughs in cable materials, construction, and electrical performance of transmission lines. Its end-to-end cable solutions are 5G ready, feature world-leading fire protection, and deliver the best electrical performance in the industry. Wireless indoor solutions, including cellular and radio communications, have also set new standards in fire resistance and download speeds.

Since its foundation in 1900, RFS has pioneered several breakthroughs in cable materials, construction, and electrical performance of transmission lines. Its end-to-end cable solutions are 5G ready, feature world-leading fire protection, and deliver the best electrical performance in the industry. Wireless indoor solutions, including cellular and radio communications, have also set new standards in fire resistance and download speeds.

As communications technology has evolved, so have RFS’s capabilities. With the expertise and agility to deliver hybrid cable configurations for any power and fiber applications, the company’s hybrid cable solutions support any network technology or frequency, and its simplified private wireless networks support and accelerate digital transformation.

Jacqui Gallacher, Managing Director, Sales, elaborates on the evolution of RFS. “The organization has changed significantly since its origins, developing new technologies in line with advancements in the communications industry,” she opens. “Today, RFS is focused on the design and manufacture of high-quality, long-life cable connectivity solutions that are used by customers in vertical markets, including transportation, mining, manufacturing, warehouses, offshore energy, broadcast, telecoms infrastructure, and stadiums, as just some examples.

“Our RADIAFLEX radiating cable, for instance, allows wireless connectivity to be emitted from the entire length of cable. It is used in more than 50 percent of metros worldwide, helping operators overcome the challenge of delivering wireless coverage in tunnels. The newer HYBRIFLEX solution meets increased demand for fiber and power technologies to support connectivity infrastructure deployments.

“We look after the design and manufacture of all our solutions and provide consultancy services to help customers achieve the complete coverage they are looking for, including assisting with any implementation challenges,” Jacqui continues. “For example, many of our customers struggle with buildings that are ‘wireless unfriendly,’ especially those in warehousing and manufacturing. Machinery, racking, and greener construction materials like insulated plasterboard and low-emissivity glass all block radio frequency signals and make achieving sitewide coverage a nightmare. We work closely with customers to overcome these challenges and enable them to achieve the comprehensive coverage needed for both business operations and mission-critical requirements.”

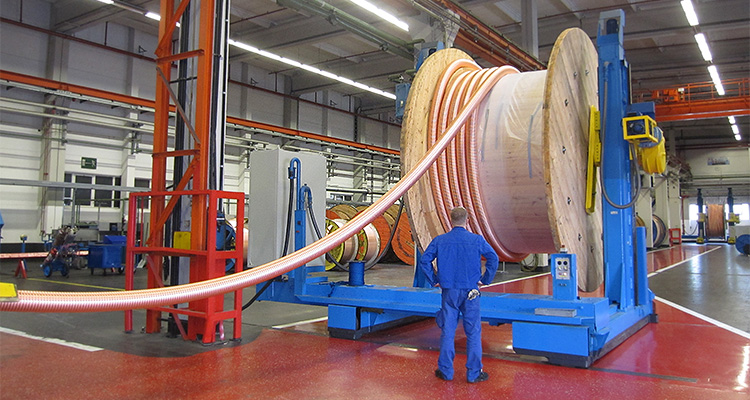

Turning to the company’s manufacturing operations, Jacqui explains why continuous investment is crucial. “We have manufacturing facilities in both Hannover, Germany, and Suzhou, China, with additional hubs all over the world, including in the UK, to support customers with their infrastructure projects,” she states. “To ensure we continue to meet customer demands, we continuously invest in our manufacturing facilities and capabilities. Our commitment to this is reflected by a seven-figure investment over the last 18 months to update our facilities with a new burn chamber, line modernization, a new punching machine as part of the cable manufacturing process and implementing dual factory supply to always maintain consistent product availability.

“At our Hannover facility, we’ve recently extended our in-house burn testing facilities, as fire safety is of huge importance to our customers, with many of them needing to comply with strict regulatory requirements about the performance of their equipment in extreme conditions. It’s essential that the mission-critical systems we offer continue to work in the event of a fire, maintaining the safety of those living or working in the building as well as emergency responders. Having an on-site burn chamber enables us to maintain our focus on designing and testing the integrity of our cable solutions to ensure we continue to supply best-in-class products.”

needing to comply with strict regulatory requirements about the performance of their equipment in extreme conditions. It’s essential that the mission-critical systems we offer continue to work in the event of a fire, maintaining the safety of those living or working in the building as well as emergency responders. Having an on-site burn chamber enables us to maintain our focus on designing and testing the integrity of our cable solutions to ensure we continue to supply best-in-class products.”

Aside from investments to enhance its manufacturing operations, RFS is also actively investing in sustainable solutions. “We completed a major project to install solar power on the roof of our Suzhou facility in 2024,” Jacqui reveals. “Covering 16,000 square meters, the panels can generate 1.49 megawatts of power and are expected to see an annual power generation of 1.35 million kilowatt hours, saving an estimated 1346 tons of carbon emissions per year. We are currently exploring a similar investment to install solar energy at our Hannover facility.

“In 2024 we also launched a private 5G network to be used for customer proof of concept (POC) demonstrations and to support our on-site manufacturing facility. It is being used by RFS to support logistics, manufacturing, and testing, with the test and measurement range, the burn chamber, and the new raw materials warehouse facility all benefiting from the network. This is also a significant project for our manufacturing and logistics customers, as it provides a working demo of what we can help our customers achieve with our connectivity. We’re not just selling products but also supporting our partners with the implementation of the ecosystem required to support Industry 4.0 projects.

“We’re currently working with several online retail and logistics companies, tailoring our solutions to meet their specific connectivity needs. We’re also continuing our work with the London Underground, supporting mission-critical communications technology for various lines including the new Elizabeth Line.”

To close the conversation, Jacqui shares what the remainder of 2025 has in store for RFS. “In 2025, we’ll continue the projects discussed, including solar installation and the continuous modernization of our facilities,” she states. “We’ll also maintain our work in vertical markets, focusing on gaining a deep understanding of customer connectivity challenges and tailoring our solutions to overcome these issues.

“We have historically evolved with the communications industry, and we’ll continue to do so, supporting 6G, AI, and other advanced technologies as they increasingly impact our customers across vertical markets,” Jacqui concludes. “As the ecosystem changes, it’s crucial that we work in partnerships with other businesses to offer a complete solution to end customers, and so we expect to see more collaboration over the next five years, with a focus on how we can best serve our customers.”