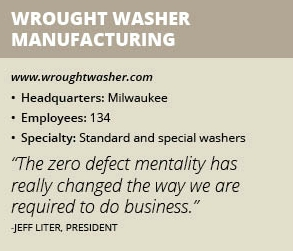

Wrought Washer Manufacturing

Founded in 1887, Milwaukee-based Wrought Washer Manufacturing is the country’s oldest manufacturer of standard and special washers. The company has been serving the nation’s leading industries for more than 130 years by supplying the highest-quality washers for a broad range of markets.

“I would say our diverse manufacturing capabilities and commitment to providing exceptional customer service has set us apart in the industry,” President Jeff Liter says. “By having over 50 stamping presses and in excess of ten million pounds of raw material we are able to respond to customer requirements in a timely fashion.”

In addition to its 225,000-square-foot Milwaukee factory, Wrought Washer has warehouse locations in Houston and Dallas, Charlotte, N.C., La Mirada, CA., and Mt. Pleasant, WI. All locations are capable of providing immediate washer delivery or pick-up service. “Our philosophy is to provide top-quality products and outstanding customer value through prompt delivery, reasonable pricing and personalized order processing,” Liter says.

Wrought Washer’s product line is ever-changing to meet the needs of today’s demanding marketplace. Over the years, the company has expanded to include manufacturing an extensive range of custom washers as well as tight tolerance machined and laser cut parts. Its products are made in the United States from steel purchased primarily direct from domestic steel mills.

“For 131 years we have stayed with stamping washers and fastener-related products,” Liter notes. “The biggest changes over the years have come in terms of quality requirements and different coatings. Customers are requiring zero defects, which has led us to camera sorting as our last operation before packaging.”

Because some of its products get sent out for plating, coating or other secondary operations, Wrought Washer uses cameras to visually sort parts to ensure no contamination is introduced during these processes. “Thirty years ago, if you had a bad product in the box the customer threw it out,” Liter remembers. “Today, with most applications being automated, one bad part can shut a line down. The zero defect mentality has really changed the way we are required to do business.”

Lean Operations

Lean Operations

Wrought Washer has increased its focus on continuous improvement. The company hired a continuous improvement champion in 2016 and has been proactive in changing the culture among new and existing employees.

“Driving our continuous improvement and quality metrics with a sustained effort to Lean Manufacturing is key to our continued success. We have started 5S and Kaizen and committed to developing our existing employee skill sets. This has driven us deeper into root cause analysis using DMAIC and PPM, and helped us receive multiple supplier awards in 2018. These activities are important for us to sustain our goal of a commitment to discipline,” Liter says.

Wrought Washer employs about 134 people and remains competitive in finding new hires. “We have a tight labor market right now with electronics manufacturer Foxconn coming in a few miles from our Mt. Pleasant facility and looking for 12,000 employees,” Liter says. “It’s in the same area as Amazon, so the employee market here is challenging.”

To combat this issue, Wrought Washer is working with local high school and vocational institutions to attract the next generation. Liter says. “If manufacturers have skilled workers they are keeping them. Our job is to find quality candidates and train. Retention then becomes a function of creating a positive environment where employees can see a career for themselves.”

Wrought Washer will continue to remain competitive with an attractive salary and benefits package and positive culture. “Our goal is to be one of the best places to work in Wisconsin,” Liter says. “We have positioned ourselves as a growing company which creates opportunities for our employees.”

Adding Value

Wrought Washer grew in revenue by about 22 percent in 2017. The company added stamping presses, CNC equipment and visual sorting equipment last year to keep up with demand.

In December 2017, Wrought Washer acquired the complete line of manufacturing equipment from ITW Shakeproof for Spring Pins and was in full production in their Milwaukee plant at the end of January. The acquisition is a result of continuously looking for ways to add value and convenience to Wrought Washer’s customer base.

Moving forward, Wrought Washer plans to continue looking for additional acquisitions that will increase its value with its distribution network. “We sell across all industrial markets, but primarily industrial equipment, agriculture and automotive,” Liter adds. “Our vision is to continue to grow and add additional fastener-related products to our mix and become more important and valuable to our customer.”