Zodiac Seats US

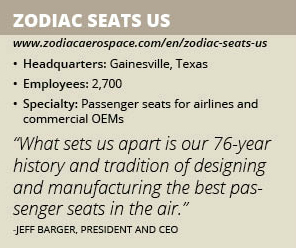

Zodiac Aerospace is a world leader in aeronautical equipment and systems for commercial, regional and business aircraft and helicopters. Based in Gainesville, Texas, Zodiac Seats US is a Zodiac Aerospace subsidiary focused on the design and manufacturing of passenger seats for airlines and commercial OEMs.

“We were founded in 1941 as Weber Aircraft and were acquired in 1992 by Zodiac Aerospace,” Zodiac Seats US President and CEO Jeff Barger says. “In 2012, we changed our name from Weber Aircraft to Zodiac Seats US to align with the rest of the Zodiac Aerospace group. What sets us apart from our competitors is our 76-year history and tradition of designing and manufacturing the best aircraft passenger seats in the air. That’s our history and legacy, and it is what has made the Weber and Zodiac Seats US brands the industry leader in economy class seats.”

Economy class seats remain Zodiac Seats US’s core business because they make up 95-plus percent of the seats on an airplane, Barger explains. “It’s typically high-volume manufacturing and the least expensive seats in the aircraft cabin,” he adds. “Business and first-class seats get highly customized and become more electrical where our seats are mostly mechanical. We primarily focus on economy class seating. However, we also produce domestic first-class seating for single-aisle airplanes such as the B737 or A320.”

In addition to its headquarters, Zodiac Seats US operates a component manufacturing facility in Chihuahua, Mexico, as well as a small final assembly line in Tianjin, China.

Designing Comfort

Airlines focus on the comfort of their passengers, which is why Zodiac Seats US is in constant contact with its customers regarding what they prefer in a next-generation seat. “Typically, our customers look for a lighter-weight seat to be more fuel efficient, while improving passenger comfort. They also look to integrate the latest in-flight entertainment technology, such as a monitor mounted in the headrest, as well as passengers being able to connect and utilize their personal electronic devices” Barger explains.

Zodiac Seats US is a design/build manufacturer, so production changes with every order. “When an airline launches a procurement effort to buy or retrofit airplanes, we provide them custom design options to meet their seating requirements,” Barger explains. “They will make some level of changes that will lighten the weight, increase the comfort and/or add the latest in-flight entertainment technology.”

Once any change – even a minor one – is made, Zodiac Seats US begins its development process. Zodiac Seats US designs and builds prototype seats at its headquarters, which are then tested and certified by the FAA and other regulatory agencies throughout the world. Once certified, the new seat model moves into production and is ultimately delivered to the customer.

“I would say a good benchmark for time to market in our business is probably 12 to 15 months from initial concept to delivery of a certified seat,” Barger says. “We are focused on reducing  that time as a future competitive advantage. In fact, we have recently delivered seats in as little as 90 days.”

that time as a future competitive advantage. In fact, we have recently delivered seats in as little as 90 days.”

To reduce its lead time, Zodiac Seats US is continually implementing lean principles. The company has become a paperless assembly operation so its work instructions and 3-D drawings are now readily accessible at the touch of a monitor. “It started here in Texas within the last year. The result has been an improvement in quality with a shorter assembly time,” Barger explains.

Zodiac Seats US utilizes approximately 75 suppliers that provide more than 80 percent of its supply base. “To help shorten lead-time, we have entered into long-term agreements with strategic suppliers that enables them to carry certain levels of inventory,” Barger adds. “The result is that we are able to reduce lead times of purchased materials and parts.”

Knowledgeable Workforce

Zodiac Seats US has about 2,700 employees across all three of its facilities. Its hourly workforce is required to participate in five days of classroom training prior to starting on the production floor. For its engineering workforce, newly hired employees complete 4 to 6 weeks of rotational training before assuming their duties. In addition, the company requires every employee to participate in at least 20 hours of online or classroom training per year.

“We have a very skilled, highly-qualified and motivated workforce which has been a large part of the turnaround over the last year,” Barger says. “This started with a more engaged leadership team, including myself. I replaced most of the leadership team I started out with 15 months ago. The characteristics I sought were leaders who are collaborative, cross-functional, people-oriented and communication-focused. The new leadership team has driven improvement in morale and performance across the board.”

Barger is proud of creating an atmosphere over the past year that is filled with appreciation. “We have a team of people that work for, and not just with, each other, which is much more powerful than anyone sitting in the corner office,” Barger adds. “It’s very exciting and rewarding to see how much the team has achieved in such a short period of time.”

Performance Improvements

By developing a culture of collaboration and teamwork, Zodiac Seats US has returned to 100 percent on-time delivery performance and profitability. “We were losing money when I arrived and now we deliver on-time and are profitable as a result,” Barger says.

Moving forward, Zodiac Seats US is certainly positioned to continue its 100 percent on-time performance while improving customer satisfaction in the quality of its seats and aftermarket service support. “Aftermarket support is the company’s ability to meet the customers’ needs over the useful life of their seats,” Barger notes.

In April, the company will reveal two new products at the annual Aircraft Interiors Expo in Hamburg, Germany. “New products, continuing our existing performance and improving customer satisfaction and aftermarket service will fuel organic growth,” Barger predicts.