Aspocomp Group

The right connection for Aspocomp

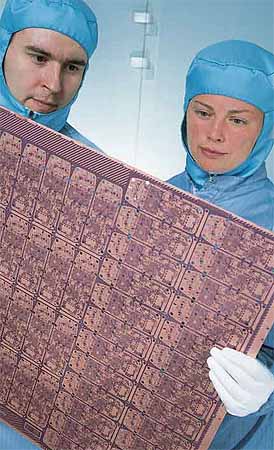

Aspocomp is one of the world’s leading manufacturers of advanced HDI PCBs (High Density Interconnection Printed Circuit Boards) aimed at the top end of the market with end applications including mobile devices and telecommunication networks.

The company utilises the latest technology, such as embedded passive components, and offers its customers early involvement in design and product development.

Aspocomp provides its global customers a fast route to mass production through flexible and cost-effective adaptation of new technologies, striving to offer solutions that enable increased flexibility in product development and close cooperation with customers.

President and CEO Maija-Liisa Friman, explains: “We are Europe’s second largest PCB producer, concentrating on the very high end of the technology with HDI. We have the most innovative customers globally and work closely with these companies from the very early stages of development.”

The company was formed in 1999 after the division of a high technology corporation into two public companies. The Group has 3400 employees in total and now consists of Aspocomp Group Oyj in Finland, Aspocomp Oy also in Finland, Aspocomp AB in Sweden, Aspocomp GmbH in Germany, Aspocomp Electronics India Pvt. Ltd. in India, ACP Electronics Co. Ltd. in China, and Aspocomp Co. Ltd. in Thailand.

Aspocomp Oy has production operations in Finland, China and Thailand, and the company began building India’s first HDI PCB plant in Chennai at the end of 2006, which is predicted to double the Group’s HDI PCB production capacity. The production facility will be established using technology and process solutions that enable flexible production and deliveries that can be tailored to meet the needs of customers. The investment is part of the company’s growth strategy to solidify Aspocomp’s position in the global printed circuit board market.

“The expansion into India is a logical step in the implementation of our strategy that has already started in Asia,” explains Maija-Liisa. “India is an attractive and rapidly growing market for PCBs and this project significantly reinforces our ability to serve our international customers. It combines high technology products, production flexibility, a good delivery capacity and a competitive cost level.”

The establishment of this new facility in India was made possible through close co-operation with a number of strategic partners. Key companies including Posalux SA, Ernst Lenz Maschienbau, Atotech Deutschland, Luther & Maelzer and Hitachi Europe worked with Aspocomp to help create the new manufacturing plant, which is due to open later this year.

In furthering its investment and growth program, Aspocomp recently acquired all shares in ACP Electronics Ltd., its China based joint venture, from its Taiwanese partner Chin-Poon Holdings for a net purchase price of 37.8 million euros. “Prior to going to India, we decided to invest in acquiring the 49 per cent minority interest of our Chinese company, of which we have been the majority owner since 2001. So now we will fully benefit from the plant’s profitability and cash flow,” explains Maija-Liisa.

Aspocomp focuses primarily on multilayer PCBs produced with HDI/Microvia technology and its strengths lay firmly in mastering state-of-theart technologies, rigorous R&D, extensive experience in PCB production and its global production capacity that maintains a conservational policy. Aspocomp’s main customers are global telecommunications companies and currently Elcoteq, Philips, Wabco, Sanmina-SCI and Nokia make up about 54 per cent of its net sales.

The company develops its environmental activities in accordance with the principles for environmental management of the Business Charter for Sustainable Development defined by the International Chamber of Commerce. Each production plant also has an ISO 14001 certified environmental management system and an action plan related to it. Aspocomp believes in ethical conduct throughout all of its operations and places great importance on creating manufacturing facilities that are ecologically sound.

“We are a very environmentally friendly company,” explains Maija-Liisa. “If you look at our new Indian plant for example, it will be a Zero Discharge manufacturing operation, which means we re-use all water and other substances going into the factory so nothing is wasted. It is important to implement such provisions, even though it is costly, because we trust that they will benefit the environment, the company and, in turn, our customers.”

In looking to the future, Maija-Liisa sees challenges that, once overcome, can bring substantial rewards: “Securing further production capacity is a major focus so it is vital that we adequately finance the project in India and additional expansion in China. Our work is very complex and there are always greater demands for more impressive technology so we have to keep up with the higher requirements of our customers and act quickly to bring new products to the market. This industry is always moving forward but our profits should rise in accordance with this. We expect global HDI PCB revenue to grow by about eight per cent annually between 2005 and 2010, with the annual growth forecast as high as 12 per cent in Asia.”

Continuing, she adds: “It is estimated that by 2010, about 90 per cent of the world’s HDI PCB revenue will be generated in Asia and in order to outpace market growth in the longer term, we are continuously working on securing development both in Asia and in Finland. I firmly believe that these efforts, although time consuming and capital intensive, are the key to growing globally, serving our customers, and ultimately creating genuine value for our shareholders.”

Aspocomp Group

Products: PCBs and interconnection solutions

Sites: Finland, China and Thailand

Employees: 3400

www.aspocomp.com