Dresser-Rand

Dresser-Rand drives the industry

Dresser-Rand’s range of advanced rotating equipment, including centrifugal and reciprocating compressors and gas and steam turbines, enables customers in the energy industry to meet their compression and energy conversion needs in an efficient and cost-effective manner.

The company, one of the leaders in its field, provides market leading solutions for oil and gas production, refining, gas processing, storage and transportation, and industrial power and energy recovery.

Dresser-Rand can trace its roots back to the 1800s, and the formation of a number of businesses that would later merge to create Dresser-Rand. During the early 1900s, these companies expanded rapidly, developing many of the latest innovations in their fields and leading the industry. In 1938, Clark Brothers merged with the S. R. Dresser Manufacturing Company to form Dresser Clark, becoming Dresser Industries in 1956.

On the 1st of January 1987, Dresser Industries combined its business with Ingersoll-Rand to form Dresser-Rand Company. Ingersoll-Rand, formed in the early 1900s by a merger of the Rand Drill Company and Ingersoll-Sergeant Rock Drill Company, was a leading manufacturer of compressors, designing the first centrifugal compressors for natural gas transmission.

By combining the considerable knowledge and experience of the industry’s leading players, Dresser-Rand is able to provide an extensive portfolio of products and services to the energy industry. The business has ten manufacturing facilities worldwide, state-of-the-art test facilities, and more than two dozen service centres and approximately 70 sales offices.

Odd Guldsten, vice president and general manager at Dresser-Rand AS, the Norwegian company operating in the European served area of Dresser-Rand, elaborates on the business: “I believe that we are differentiated from many of our competitors in that we are one of the few companies capable of providing complete solutions in compression and power generation for offshore topside production facilities that are owned and operated by oil and gas companies. We specialise in developing state-of-the-art solutions for offshore clients, pipeline owners and operators and gas processing plants.

“Our clients are predominantly the large oil and gas companies, and the associated engineering, procurement and construction companies that work with them,” says Odd. “Close co-operation with our clients is vital in our operations as all of our products are tailor-made to meet a specific requirement. We work with them during the design and development stages of a solution, undertaking feasibility studies, and working to their very exacting specifications.”

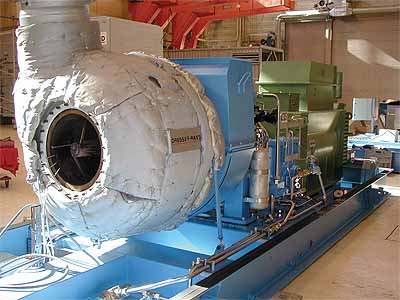

Odd explains that the company has recently introduced a 30 MW gas turbine single-lift unit to improve efficiency and production time for its clients: “We are witnessing an increase in floating production in the oil and gas industry, involving the conversion of old tankers. This type of production, and conversion, require generator and compressor sets to be supplied on a very short time scale, not just a prompt delivery time, but a short time from the initial contact to the finished product in operation.

“To alleviate some of these problems we have designed and manufactured a 22 metre long skid that features all of the control mechanisms, the gas turbine, the generator or compressor, and all of the auxiliary models,” he continues. “The advantage of this is that it requires very few client interface points at any stage, and it is a completely integrated system that is ready for operation.

“Additionally, the system can be easily installed on three point-mounted skids on board the vessel, in a very short installation time,” Odd explains. “A typical installation/commissioning time for a classic solution takes around five months, whereas this design can be installed in less than two months. This cuts the total cycle time considerably from contract to operation. This new design is particularly focused on the current trend to floating production in the industry.”

Odd elaborates on the recent focus on FPSOs (Floating, Production, Storage and Off-loading units): “It is an extremely hot topic in the industry at the moment because everyone is aiming for shorter times to production from their oil and gas fields, and in Norway we have around ten owners investing considerably. Most of the major fields or units need power generation and gas compression, so we are in a strong market that is expanding considerably. The FPSU sector demands products that are different from those on fixed structures (because they are on a ship, they move a great deal; this requires very different design considerations).”

In its Norwegian facility, the company uses an innovative approach to provide these solutions efficiently: “The industry is very cyclic, and to combat this we have our own workshops for packaging and testing, but we do not have a labour force of our own. We have an alliance with a large Norwegian business that provides us with the required manpower when we have a packaging requirement. We can have up to 100 people in the plant in a busy period, but then we man down until we have large projects again, which benefits us considerably in terms of maintaining cost-effective and flexible operations.”

Together with the developments in FPSOs, Odd believes that the industry in general is in a buoyant position: “We provide very important products and solutions to the oil and gas industry, and it is a very active market at the moment. The key challenge for us will be to ensure that we continue to satisfy client needs, both by keeping the project cycle time low and providing the products to suit all requirements.

“It is hard to make long-term plans in the oil and gas sector, but we have to learn to live with the cyclic nature of the business, and to be ready for both the good and the bad times. This means that we have to remain lean, fast and productive. With efficient manufacturing, value stream mapping and a scientific approach to project execution it is possible to be competitive in a high cost country such as Norway,” Odd concludes.

Dresser-Rand

Products: Rotating equipment solutions

Sites: Global

Employees: 100 at peak times (Norway)

www.dresser-rand.no