Finnveden Powertrain

Powertrain is the perfect partner

As a leading supplier to the international automotive industry, Finnveden Powertrain develops and manufactures complex precision components and sub-systems

Through its made-to-order products based on metallic materials, the engineering company has established strong positions in selected market segments and focuses on supplying products for engines and power transmission.

In March 2007, Finnveden sold the Powertrain Components business area to Italian precision engine components manufacturer Gnutti Carlo S.p.A, giving rise to one of the world’s leading suppliers of precision components for heavy diesel engines. The combination of increased size, improved production and enhanced process expertise has created a strong business partner for customers in the international automotive industry. “This acquisition has led to the formation of a world-leading supplier of engine components,” comments managing director Hans Linner. “Our product range includes connecting rods, different types of turned parts as rollers, pins, shafts, high pressure connectors, cam followers, lifters, bridges and rocker arms.”

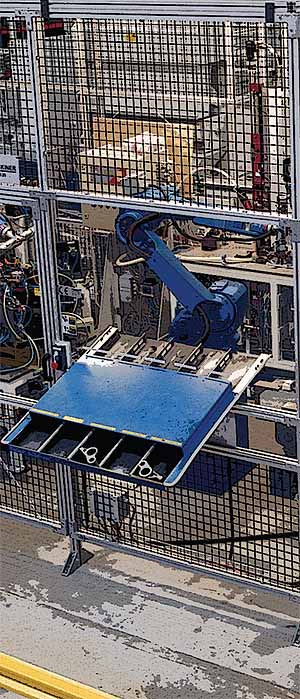

The largest product area of Powertrain is components and sub-systems for diesel engines, such as valve actuation and connecting rods. Other products include precision parts, components and sub-systems for fuel-injection systems, transmissions and brake systems. Its developmental knowledge and expertise in industrial production enable it to offer customers within the automotive industry a complete service from development to delivery. In addition to its headquarters in Gothenburg, Sweden, Powertrain has its own companies in the UK, Germany, Poland and the US, and manufacturing takes place at four locations in Sweden, Poland and in the UK. Each factory specialises in its own area and the main production processes include machining, turning, heat treatment, and assembly. The company maintains its success by investing eight million euros each year into machinery, both due to increasing volume and new products.

Powertrain has roots dating back over two decades when Finnveden Invest AB started by developing local trades in the small-scale business district of Finnveden in Sweden. “Finnveden was founded in 1982 and the name is related to a region around Värnamo, where the head offices were originally located,” explains Hans. In 1995, the company changed its name to Finnveden AB and focused on becoming a global supplier to the automotive industry. Throughout the 1990s, Finnveden was restructured and grew rapidly, making several acquisitions that currently comprise 75 per cent of the company. Four hundred million Swedish kroner was invested in new production equipment and the head office was moved to Gothenburg, which helped to reach new customers in Europe, North America and Asia.

In 2005, Swedish private equity company Nordic Capital bought Finnveden and consequently Bufab, the business area that traded fasteners to the general industry, was disbanded in order for Finnveden to focus completely on the automotive industry. Finnveden has since established a presence in new geographical markets and is the preferred partner to the automotive industry in the entire flow, from concept and product development to production and delivery. “When Nordic acquired Finnveden it consisted of four business areas; Metal Structures, Powertrain, Fasteners and Bufab. The separation of Bufab created more focus on the other business areas, “ says Hans. “Our main customers today are Volvo, Scania, Caterpillar and Bosch. Finnveden Powertrain is an international supplier of highly engineered precision parts, components and sub-systems for powertrain applications to the automotive and heavy-duty diesel engine original equipment markets.”

Ongoing developments help Finnveden to remain dynamic and production resources have recently been extended in Poland. Finnveden Production System was developed as a tool to continuously improve all operations and production processes in the group and, alongside the development of its industrial structure, the company has strengthened its technical resources so it can handle the entire supply chain from development to delivery. “Our production system will guide us in exceeding our customer’s expectations,” says Hans. “It will aid us in achieving our main goals. We also aim to increase the value of our services to our customers by offering product development engineering. Some of our customers request this competence and service and it is important to understand how our products work.”

Hans believes Powertrain’s success is due to a mix of efficiency and good partnerships: “The company’s key strengths are quality, competence, good service and daily contact. Our success is based on superior processing skills, using state-of-the-art technology, and cost effective production systems. We have close, daily contact with customers regarding planning, quotations, delivery, cost reduction, and improving quality. We have both customised machinery for use in high-volume production and standardised machinery for lowvolume and prototypes.”

Powertrain is progressively globalising its operation, particularly in the US and Asia, winning major new contracts and responding strongly to increasing demands from customers. Its solid foundation facilitates continued development and Gnutti Carlo provides the necessary financial support for future plans. “The market is very demanding regarding price, quality, production flexibility and deliveries,” concludes Hans. “Our main challenge is to continuously improve in these areas as part of our mission to become the preferred partner. We will continue to develop and strengthen the synergies between Finnveden Powertrain and Gnutti Carlo in order to be a worldwide producer of precision components for heavy diesel engines.”

Finnveden Powertrain

Products: Engine components for powertrain applications in the automotive industry

Sites: Sweden, UK and Poland

Employees: 900

www.finnveden.com