Genzyme Ireland

Genzyme’s prescription for success

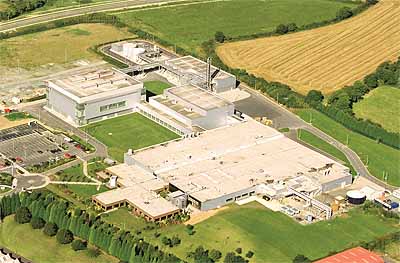

Genzyme Ireland, established five years ago by leading biopharmaceutical company Genzyme, manufactures a number of important biotechnology products for patients around the globe.

The company produces a range of enzyme replacement therapy treatments, such as Myozyme and Cerezyme for niche worldwide patient markets. In line with Genzyme’s expansion plans, the Irish business is currently in the process of developing a third production facility for its renal product line.

Dominic Carolan, vice president and general manager at Genzyme Ireland’s Waterford manufacturing facility elaborates on the company’s background: “Genzyme is a market-leading biotechnology company headquartered in Boston, USA with 25 years of industry experience.

“In 2001 the company decided to establish a manufacturing site at our current location in Ireland to complete ‘tabletting’ operations for the manufacture of Renagel, which is a polymer product used to treat dialysis patients. In subsequent years Renagel has gone from strength to strength, with sales exceeding 400 million euros in 2005.

“Following the success of the initial manufacturing site, Genzyme opened a second facility, which is a sterile fill/finish plant for the production of biological proteins and enzymes,” Dominic continues. “In this facility, we are currently manufacturing Thymoglobulin, for acute kidney transplant rejection, as well as Myozyme and Cerezyme, which are presently going through the process of gaining global approval. In addition to our established facilities, we are building a third manufacturing plant, which will be an expansion of our existing renal line, in response to the success of Renagel. We expect this facility to be in full commercial operation by the middle of 2008.”

Dominic believes that the new development will benefit the business considerably: “We are investing over 60 million euros in the new facility, which will bring total investment at the Waterford site to approximately 260 million euros. The third production facility will provide us with additional tabletting capacity to enable us to grow in this sector in the future and it will provide the opportunity to add line extensions to the Renagel range.”

Genzyme Ireland’s oral dosage manufacturing capabilities consist of a solid dose tabletting production facility, two packaging lines and a multi-dose, multiscale development facility. At the site, the company’s tabletting and packaging teams focus on the manufacture and packaging of Renagel, converting bulk active materials into solid dosage tablets and packaging the product into bottles. At every stage of the operation, a dedicated process engineering team supports the tabletting and packaging team, focusing on on-going monitoring, trouble-shooting and general improvement of the production and packaging processes.

In addition to oral dosage production, the company’s fill/finish manufacturing facility comprises of a three-storey production building, a central utility site and a logistics area. Designed as a multiproduct facility, the fill/finish complex is capable of filling vials ranging from 5ml up to 50ml at speeds of 100 to 300 units per minute. Manufacturing processes at the facility include formulation, sterile liquid filling, lyophilisation and capping. To ensure the highest levels of quality and product protection, the liquid filling lines utilise isolation technology, and an automated load and unload system is used for the lyophilisers.

Dominic explains that the key to Genzyme’s success is its dedication to developing innovative solutions for niche products in the bio-pharmaceutical arena: “We have a particular focus on meeting the unmet medical needs of the market. The majority of our products are orphan drugs, which are essentially for a very small patient population. We primarily focus our research efforts in developing solutions for these niche areas.

“We are particularly strong in enzyme replacement therapies, a fact that is well recognised throughout the biotech industry,” he continues. “For example, two of our main products, Myozyme and Cerezyme, are niche products designed to only be used for specific ailments. Even Renagel, our most popular product, is developed specifically for patients on dialysis, of which there are only around 350,000 worldwide.”

Renagel is a unique, calcium and metal free phosphate binder that is indicated for the control of serum phosphorous for patients with Stage 5 Chronic Kidney Disease, who are on haemodialysis. As Renagel is a non-absorbed treatment it controls phosphorous without the concerns of calcium or metal accumulation. Among Genzyme’s most popular products, Renagel has been used by more than 300,000 patients worldwide in six years.

Genzyme Ireland’s products are distributed to customers around the globe through the company’s extensive sales and marketing network: “We are a core manufacturing company. So essentially we supply our products into the wider supply chain within the Genzyme Group (Corporation),” says Dominic. “We ship directly to areas in the EU and the US that have country specific Genzyme operations.”

The nature of the company’s products means that continuous development programmes are essential: “We have a dedicated development facility at Waterford for oral dose products, which completes formulation development programmes and manufactures clinical supplies,” Dominic explains. “This area of the business focuses on developing and producing clinical materials and products for testing in phase three clinical programmes.”

The company’s Oral Dosage Development Facility in Waterford has been in full operation since March 2003. Together with the production of clinical trial materials for phase three testing, the facility undertakes the execution of registration batches in support of new product approvals, process development, and oral dosage formulation development.

Operating in full compliance with the relevant safety and cGMP requirements, the development facility is capable of handling batch sizes ranging from 50 to 100 kg for solid dose formulations, and up to 1000 litres for liquid formulations. The site uses the latest process technologies, including wetting/granulation processes, milling, blending, compression and film coating, oral liquid bulk manufacture and filling, and sachet powder blending and filling.

“Developing products for specific use in niche areas does bring many challenges, and we have recently been expanding our efforts to more broader based, therapeutic areas besides enzyme replacement therapies,” he continues. “For example, we have recently been involved in oncology, where we have a number of pipeline products coming through.

“In addition to these developments Genzyme has an orthopaedic business division and a diagnostics division,” he continues. “The diagnostics side of the business is particularly important as our key objective in developing all our products, particularly the enzyme replacement therapies, is trying to identify patients with those specific ailments we wish to treat.”

Dominic elaborates on some of the company’s product range: “Myozyme is a very recent addition to our portfolio, which received commercial approval at the beginning of 2006, and is designed specifically to treat patients with Pompe Disease. Cerezyme is the product on the back of which Genzyme has grown, and was the first commercial product to be manufactured and sold. Genzyme was a single product company up to around 1994, but subsequently started to diversify. In recent years we have diversified our product range quite substantially.

“We have a number of new products currently going through phase three clinical trials,” Dominic continues. “One is for the treatment of c-Difficile, which is a bacteria born infection that is analogous to MRSA. It is going through the various clinical trials at present, and we hope that it will enter the market during 2008, and will be manufactured at our facility in Waterford.”

Before entering production, Genzyme’s products have to go through a number of rigorous trials: “The regulations in relation to our products are very strict,” says Dominic. “For example, we would initially develop a new product at Waterford, but because the manufacture of it is in accordance with cGMP, it needs specific approval from the Irish Medicines Board as an Investigational New Medicine. The clinical trials are carried out in the US and Europe, and of course there are very strong regulations in relation to the structure of those clinical trials.

“We have a number of on-going trials at present for the new drug to treat c-Difficile, and on the basis of a positive outcome we will look to launch that product into the market,” he says. “In addition to approval from the FDA and the EMEA for the product itself, we also need approval for the manufacturing facilities. Following this, we may also require each market region to obtain commercial approval from the relevant local regulatory authorities.”

As it has developed, the company has significantly improved its manufacturing processes: “Our initial tabletting operations started as manual processes,” Dominic explains. “But following considerable investments we are now in the last stages of implementing manufacturing execution systems (MES) on site, including electronic batch records. In our new facility we plan to install the latest technology, including automatic goods vehicles and totally automated manufacturing processes.”

Looking to the future, Dominic is confident that Genzyme Ireland can continue to play a key role in Genzyme’s global success: “I think we are well positioned in Waterford as Genzyme’s key secondary site outside of the US, which will give us great opportunities to line in and link up with the company’s general expansion plans. Future growth will occur through a combination of organic development and acquisitions, which take place regularly, and will continue to do so in the future.

“The key challenges for us in moving forward will be to continue our own strong growth pattern, whilst developing in line with Genzyme’s expansion strategy,” he said. “Additionally, we need to invest in the future of the business by hiring employees with the numerous skills needed for the highly complex operations we are involved in.”

“Genzyme Ireland is an industry leader, and respected provider of the highest quality biotechnology products and I believe that we can continue to experience the strong growth rate we have achieved over the past five years. We have very clear plans for the medium term for product introductions, right through to 2009, and we hope to be able to support those whilst creating a sustainable platform for future growth beyond the medium term,” Dominic concludes.

Genzyme Ireland

Products: Bio-pharmaceutical products

Sites: Ireland

Employees: 320

www.genzyme.ie