Integral Powertrain: Revolutionizing Electric Motors & Inverters with Key Automotive Partnerships

Breaking limits

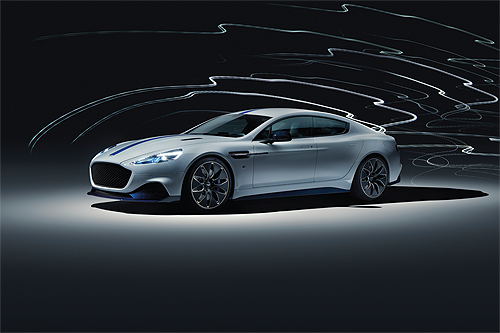

Successful collaborations with the likes of Aston Martin and Volkswagen have made the name Integral Powertrain synonymous with high-quality electric motors and inverters

The 20th anniversary of the company’s formation celebrated by Integral Powertrain in 2018 coincided with an exciting period of development at the powertrain and e-Drive solutions provider. Having undertaken the process of transforming from a consultancy business into an engineering manufacturer, the last year and a half has seen the organisation continue to pick  the fruits of its labour, with the development of new products leading to its winning of a number of prestigious industry awards, too.

the fruits of its labour, with the development of new products leading to its winning of a number of prestigious industry awards, too.

“The development of our ever-increasing product line has definitely raised the profile of the company and the technology we have created,” begins COO, Alan Cherrington. “Our programmes with Aston Martin (on the Rapide E and Valkyrie), where we are the electric motor supplier for these vehicles, together with the work for Volkswagen Motorsport on the Pikes Peak ID.R vehicle have contributed significantly to the growth of our reputation, whilst allowing us to add to our product capability.”

It was Integral Powertrain’s e-Drive division that supplied the electric motors and inverters that powered the ID.R race car to an impressive victory and a new record at the Pikes Peak International Hill Climb in Colorado Springs, shattering the previous peak achievement by over 16 seconds. A few weeks later, another record was set at the Goodwood Festival of Speed Hill Climb. No wonder then that the company’s technical excellence and innovation have been acknowledged by a range of institutions. Among the awards won by Integral Powertrain are the 2018 Motorsport Technology of the Year (presented by Professional Motorsport World), the Race Powertrain of the Year Award (by RaceTech Magazine), the Technology and Innovation Award (by the Motorsport Industry Association), as well as the 2018 Milton Keynes Technology of the Year and Business of the Year awards at the Milton Keynes Business Achievement Awards. The Dewar Trophy presented by the Royal Automobile Club tops off this impressive list.

“Some other projects our e-Drive business has been engaged with, include the launch of an e-Axle (CTU 400) developed with McLaren Applied Technologies and Hewland, as well as the government-funded programme to develop a UK electric motorcycle capability alongside Triumph Motorcycles,” Alan points out. “All of these products are key enablers for high-performance hybrid and battery electric vehicles and these technologies are instrumental in helping to reduce CO2 emissions. The key thing is that the electric motor and inverter technology is not wedded solely to battery EVs. Instead, they can also be used in hybrid, solar, and fuel cell vehicles,” he adds.

Following the resounding success of its e-Drive division, in 2018, Integral Powertrain took the strategic decision to invest in a new, state-of-the-art technical centre in Milton Keynes that is scheduled to be completed in mid-2020. Alan comments: “The new site will allow us to co-locate our engineering teams who are currently spread across four other sites. The technical centre will be three times bigger in floor area than our engineering centre at Bletchley and by bringing our teams together, it will allow us to be more efficient in developing more innovative products.”

While undoubtedly the most important ongoing investment made by Integral Powertrain, the technical centre is by no means the only facility that has benefitted from the company’s keenness to constantly improve its infrastructure. Not long ago, the business initiated a multimillion-pound upgrade to its two-wheel drive and four-wheel drive emissions test facility for the latter to be able to run the latest duty cycles and emission tests, including climatic capability.

In Alan’s opinion, one of Integral Powertrain’s key selling points, is the power density of its technology. As such, he is confident that the opportunities to bring the technology to various applications are wide and varied. “To give you an example, lightweight power dense motors and inverters fit aerospace applications very well and we are already looking to utilise our capabilities in the aerospace market.

“The range and the efficiency of an aircraft are influenced by many factors, including overall mass,” he explains. “As the packaging volume in an aircraft is relatively small, it is vital that any products or systems are packaged neatly, i.e., they need to be as small as possible. We also have to remember that the cost to create power dense products is not insignificant. At the same time, the budget to reduce mass is greater in an aerospace application than in an automotive one and, therefore, the use of some of our more extreme technologies and the utilisation of high-performance materials are justified by the resulting increase in performance and the reduction of the product mass. Taking all these considerations into account, we feel that the aerospace industry provides a favourable soil for us to grow a presence.”

Another area where Integral Powertrain is actively pursuing to bring its technology to, is road vehicles. “Drawing upon our expertise in the high-performance vehicles market, the main challenge is how to design, develop, and manufacture the technology at a cost that is accessible for automotive applications,” Alan observes. “Our team spends considerable time to ensure that we can enter various markets with our products. It would be good to be able to work across multiple sectors, because this will enable our future growth and allow us to diversify a bit.”

Outlining Integral Powertrain’s goals for the years to come, he shares his ambition to see the company move into higher-volume manufacturing, the goal being an estimated 10,000-15,000 units per year. “The high-end automotive and aerospace sectors are the Powertrain logical markets where we will be looking to win new contracts. In the meantime, we will be expanding our motorsport and automotive product ranges and we are also planning to develop a new manufacturing facility. Finally, we are presently evaluating the requirements of various other engineering sectors to identify where our expertise is best suited and we are quite excited where this might lead us in the future,” Alan concludes.

Integral Powertrain

Products: Powertrain and e-drive solutions; consultancy services

https://integralp.com