Lambert Engineering

A winning formula

A solid combination of values and world-class engineering skills set Lambert Engineering apart as a multi-award winning innovation partner

At 2015’s The Manufacturer MX Awards one company stood out amongst the rest, winning four awards including the main prize of Manufacturer of the Year. Also winning the Customer Focus, Innovation and Design, and Leadership and Strategy awards, Lambert’s success at the awards topped off another year of significant growth that saw it reach sales in excess of £20 million. Founded back in 1973 by Chris Lambert and Peter Wainman as a small engineering shop, four decades of experience define the company’s current offering to the market that make it a leading innovation partner in the development of bespoke automation systems.

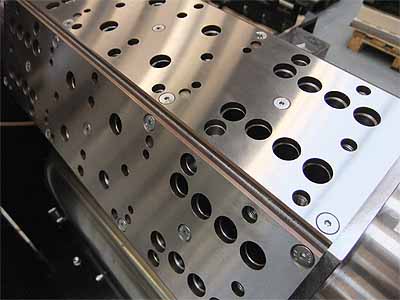

“At present we have 190 people split across three individual business units,” begins Sales Director, Matthew Cox. “The first is automation systems (AS), which accounts for around 50 per cent of our sales, and is essentially the design and build of specialist automation machinery. The second is our equipment engineering (EE) division, which allows customers to operate on a build-to-print basis, whereby they design the system and utilise our manufacturing expertise to realise it. This accounts for an additional 40 per cent of our business. The remaining business then comes from our precision components (PC) segment, which focuses on parts.”

In approaching its working relationships, Lambert very much considers itself a key partner to globally leading clients, mostly coming from the healthcare and FMCG markets. In cementing these partnerships, and in order to capacitate future growth aspirations, in 2014 Lambert 187opened its state-of-the-art innovation centre. Named the Peter Wainman Innovation Centre, after the company’s co-founder, the facility reinforces Lambert’s pro-active approach to research and development – the cornerstone of its market offering.

“The first rationale behind the centre’s development was the need to help our customer base to develop products as well as the processes that go along with them,” explains Matthew. “They have to be developed at the same time to make a good use of time and money – it is pointless developing a product that can’t be manufactured effectively. In the past we would reverse engineer some of the products to make them automatable, but now we make sure to get involved right at the start, in some cases actually developing some of our customer’s products in their entirety. This is why working partnerships are crucial.

“The other driver was to fully develop our service offering to the client. It is to become closer to the customer, to promote the whole idea of partnership and to allow us to differentiate our customers so we are giving them something really special and unique. Something that would never go to their competition.”

In 2007, Lambert was subject to a management buyout, which has seen its sales increase from £8.5 million to the £20 million-plus that it now experiences. Looking forward the company sets its aspirations on 90 per cent growth over the next five years. Commenting on the company’s ability to achieve such levels of growth Matthew puts its strength down to its clear vision, breadth of offering and the skills of its people. “I see that our focused strategy and sense of knowing precisely where we are going and how we are going to get there makes us stand out as a business,” he says. “Then, without our people and their skills we wouldn’t be able to exist. They are part of our mission statement of empowerment – we empower them and make them the best they can be and this is vital to the continued success of the business.

“In addition to this we have a great set of ethics and values, and we tend to align ourselves with customers who share these. This is all about establishing strong partnerships both with our customers and suppliers, creating an environment that allows everyone to add as much value as possible. The final thing that sets us apart is our technical excellence. Operationally, we try to be as enlightened as possible, as lean as possible and as cutting edge as possible with regards to the tools and expertise we can bring.”

creating an environment that allows everyone to add as much value as possible. The final thing that sets us apart is our technical excellence. Operationally, we try to be as enlightened as possible, as lean as possible and as cutting edge as possible with regards to the tools and expertise we can bring.”

Placing this robust proposition within the context of current market conditions suggests that the future for Lambert looks positive. Matthew notes his confidence in the strong market, particularly pointing out the continued drive towards innovation and product development that exists within many industries around the globe. “Every big international market leader is in that position because they come up with clever and innovative products on a consistent basis,” he says. “This is how they stay ahead of the competition. We don’t really see this changing much, as even throughout the last recession the company performed extremely well because it was focused on those areas of new development and innovation.” By operating in its core healthcare and FMCG segments on a global scale Lambert is also able to avoid exposure to difficult sectors that are subject to political and economic influences, such as the oil and gas market.

Considering this is the case, it is no surprise that Lambert’s target over the next five years is to grow to sales worth £35 million. The next 12 months will be key to supporting this as the company focuses on growing its talent with young engineers and graduates, expanding its service offering to the market, both before and after the point of sale, and adding to its customer base. By continuing to serve the unique needs of global leaders as a critical innovation partner, Lambert looks set to experience a long and prosperous future.

Lambert Engineering

Services: Produce bespoke turnkey automation solutions for specialist assembly need