AB Elektronik

Sensing opportunities with AB Elektronik

Engineering a wide variety of automotive electromechanical sensors, AB Elektronik GmbH is a subsidiary of the English-based TT Electronics PLC group.

Founded in Werne, Germany, in 1967, the company began its life manufacturing pro-set potentiometers and rotary switches. Establishing its own construction department in 1973, it entered the industrial electronics market the next year. 1976 was a significant year for the company as it enlarged its range of products for industrial applications and antenna technology, before commencing its activities within the automotive industry.

In just 20 years AB Elektronik has developed from a beginner in manufacturing rotational speed sensors to one of the industry’s leading sensor suppliers. A part of this progress has been facilitated by the 1987 construction of a new facility in Wahrbrink, before the TT Group’s 1993 acquisition of the AB Electronic Products Group brought further investment into the company.

With a reputation as a focused, global electronics business, TT supplies the world’s leading manufacturers in the automotive, telecommunications, computing and industrial electronics markets. From its UK base, the group has achieved a truly global reach, establishing technical and manufacturing facilities in strategic countries in order to maintain its close customer contact. Focused on understanding the needs of its clients, and providing tailored solutions, TT continually invests in modern manufacturing equipment and the development of new technologies.

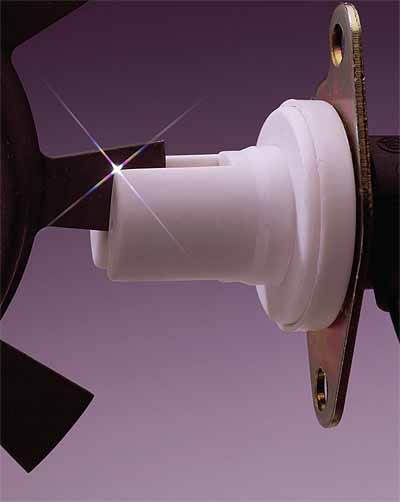

In line with this strategy, the group helped fund extensions to AB Elektronik’s production facilities in 1995, 2000 and 2002, as the German-manufacturer accommodated its growing line of products, including contactless accelerator pedals in 1997. Today the range of customer-specific products has been expanded further to include a wide selection of sensors, from seat position, indoor temperature, and steering wheel, through to ABS, crankshaft, camshaft and TPS, amongst many others.

“We design electromechanical parts for the automotive industry, supplying BMW, Daimler-Chrysler and VW with this broad selection of sensors,” explains Thomas Rinschede, sales and marketing director. “We are the single-source of accelerator pedals for Daimler-Chrysler’s trucks and Mercedes Benz’s passenger cars.”

As every sensor is customised to meet the needs of each project, Thomas explains that AB places significant importance on developing close working relationships with its customers: “As we only offer bespoke products, we often co-operate to design the whole specification together. This is quite a prolonged process, because, if, for example, we are creating an accelerator pedal, we have to allow up to three and a half years before production can start, to allow us to fully design it and perform at least one winter and summer test.”

Working so closely with its customers, and implementing this rigorous test process, ensures that AB supplies some of the industry’s highest quality products. Outlining the company’s other key strengths, Thomas continues: “We have approximately 130 patents, giving us a significant advantage over our competitors. We are particularly strong on creating cheaper designs and using new materials and technologies. Our strong customer relationships mean that we are involved very early in the design of a new model or engine, while we also have a number of sales engineers on the road, who regularly bring us new ideas from the clients.”

With such a strong emphasis on R&D and customer collaboration, the company is frequently adding to its broad portfolio. “We introduce a minimum of ten to 15 new products into our production every year, which requires us to invest significant resources in implementing new technologies,” Thomas explains. “One of our latest developments is inductive technology, which will be used in production for a number of different applications, including accelerator pedals and contactless sensors for rear brake pads.”

As AB Elektronik is continually looking to expand its range of products, the company will inevitably need to develop its facilities. “At the moment an expansion is still in discussion, but we will need extra production space for all of the new products that we would like to start manufacturing within the next two years,” says Thomas.

While the company is constantly looking to expand its production, it also emphasises the importance of running an efficient operation. “We operate lean strategies to ensure we offer costeffective production,” comments Thomas. “We have a plan for the future to ensure that we reduce our use of raw materials, and a have a number of other good ideas to improve our level of efficiency.”

Together AB’s focus on efficiency, product development and expansion form the heart of its strategy to develop its business beyond the competition. Commenting on its current position, Thomas says: “I think over the last two years the business has been running better than ever before. Obviously you can never have enough resources in the R&D department, but we are handling a lot of enquiries from customers, and ideas for new technologies and applications.”

With so many suggestions for further developments, Thomas believes that there is strong potential within the industry: “There is a large area that we can grow into, both in the passenger car and commercial vehicle market, as well as new sectors. Up to 2010 I expect another surge of technological changes as an increasing numbers of electromechanical sensors and actuators are installed.

“For example, BMW has started using the first electrical water pump, which other competitors will follow. This new water pump will reduce electrical usage and fuel consumption, in line with the tightening emissions legislation. These regulations will lead to a lot more new technologies and ideas for the future, as companies try to meet the necessary emissions rate.”

Elaborating on how he hopes AB Elektronic will deal with these imminent changes, Thomas continues: “Currently positioned on the components side of the industry, we would like to become more of a module supplier. By 2010 we would like to increase the turnover of all of our areas by at least 20 per cent, while develop new technologies, secure more patents and create innovative solutions and applications. One particular area of interest will be the potential development of hybrid cars, and how we can serve this sector.”

AB Elektronic

Products: Electromechanical sensors

Sites: Werne, Germany

Employees: 850

www.abelektronik.de