CeramTec

CeramTec provides competence in high-performance ceramics

Based in Germany, CeramTec AG is a pioneer in the conception of new solutions using high performance ceramics, with more than a century of experience in development and production.

Its product range (consisting of more than 10,000 components) aids the running of major industries, as highly specialised ceramic materials possess unique mechanical, electrical, thermal, and biochemical properties. With subsidiaries in 15 countries worldwide, CeramTec’s success is based on a balanced combination of developing new products, highest levels of quality, and superior customer-specific system solutions.

“CeramTec is a specialist in engineering ceramics and our broad product range varies from medical through to consumer, industrial, automotive, and electronics applications. We are organised in business units as profit centres,” explains head of the Electronic Applications division Dr Alexander Dohn. “My business unit is focused on all ceramic components used in electronics where the function of these products is vital, such as in components for medical equipment like pace-makers or air-bag-system for the automotive industry. Wherever you need reliable functions you will find ceramics as base material. Our key customers in the electronics applications division are the automotive suppliers, space and aircraft industry suppliers, passive and active component manufacturers, and the telecommunications industry.”

CeramTec’s Medical Applications division is expanding in the medical sector with the construction of a new 40 million euro medical plant producing bio-ceramics, built in Marktredwitz. “Ceramic is ideally suited for use in the medical sector due to its durability,” says Alexander. “CeramTec is working on items such as spine support components, hip joints, and artificial knees. CeramTec’s Electronic Applications division also produces parts for the medical industry where patients require assisted breathing or precise dosing of medicaments.”

CeramTec focuses on maintaining manufacturing efficiency and its highly skilled personnel is a valuable facet of its success: “We maintain productivity through continuous improvement activities and retaining competent employees,” says Alexander. “Good ideas are generated by our team and swiftly actualised in dedicated workshops. We are currently investing in very precise equipment and our workforce has a high knowledge of the unique behaviour of ceramics. We use modern management systems to facilitate improvement and intensively educate all staff in my division on Six Sigma.”

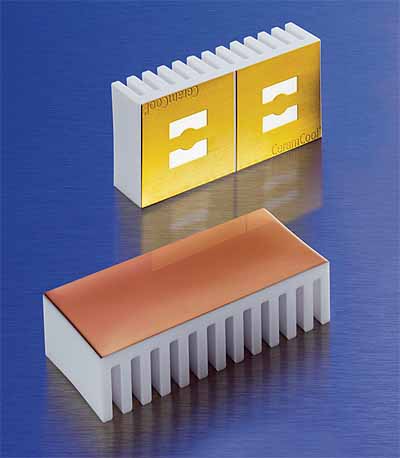

CeramTec’s dedicated R&D team continuously strives to innovate and expand its product range. The company’s latest innovation is CeramCool, providing efficient and reliable thermal management for power LEDs, electronics with high brightness, and extensive potential applications. Excellent reliability and heat conductivity offer a simple yet highly effective solution for thermally sensitive components and circuits. “This product is not only a heat sink, but a substrate as well,” explains Alexander. “Heat removal from a hot system is minimum twice as effective compared to the conventionally performed configuration plus there are less components, which means assembly is much simpler. Ceramic withstands temperatures of 1000 degrees, is inert to aggressive chemicals, and the loading performance is much higher than with metal, which opens the door to new designs, higher levels of miniaturization, and much higher heat densities. Ceramic offers superb thermal performance, which brings potential to the future and provides a solution for the electronics industry wherever heavy duty requirements occur.”

Continuing, he adds: ”Success for other new applications is likely judging by the recent LED fair in Korea where we run out of brochures after just two of the four days it lasted. We were the only company present to offer a solution for thermal management and the reaction was overwhelming. Ingenious products such as CeramCool can be modified specifically to customers’ needs and achieve technical performance targets already exceeding today’s market requirements without compromises.”

Alexander believes that new products such as CeramCool keep the company’s performance range fresh which pleases customers and allows growth into other areas: “New products are the key to our success and about 95 per cent of our products are tailor-made to ensure an improved productivity at our customers’ sites. Competing with Asia means we must offer our customers a good balance of “price to value” to their products. We sell a chance to make a better business and our customers buy our products to be successful in their own markets. Our highly qualified R&D team is currently developing solid oxide fuel cell technology and we are already prepared supplying ceramic components for fuel cell systems striving for the industrialisation of that technology. We are recognised in the market as a qualified partner working with revered companies on crucial development targets.”

CeramTec’s biggest challenge arises from increasing pressure to balance high quality service with cost effectiveness: “There is a certain race with competing products because there is the requirement of high performance combined with the need for reasonable costs,” explains Alexander. “I believe that a high-performance product has its fair price and customers welcome our performance so they accept the price. Market requirements have become tougher but it is clear that we stand out in product ranges. Asian producers are entering these markets with very low prices, but we maintain everywhere the customer needs real solutions, we can successfully serve them.”

CeramTec continues to forge successful relationships with customers and suppliers including the global Alcan International Network, which supplies aluminium oxide from Alcan Specialty Aluminas Europe, needed to create high performance technical ceramics. “The future of our company is quite positive because we are focused on high performance products and we are well established,” concludes Alexander. “Close partnerships are the best way to progress in the future and Alcan is a dependable supplier – we can rely on the quality of its raw material products and have a very valuable partnership.”

CeramTec

Products: High performance ceramics

Sites: Germany

Employees: 500+

www.ceramtec.com