Viena International

Viena International is all tooled up

Viena International is a leading, fast developing toolmaker and stamping business that specialises in the design, development and production of a range of stamping tools, precision machine tools, stamping parts, associated parts and components, and jigs and fixtures.

Eduard Sustr, managing director at the business elaborates on the company’s current operations: “Viena International specialises in the design, development and manufacturing of stamping tools such as cutting, bending, drawing, single, transfer and progressive tools, the stamping of metal parts, the assembly of hardware and metal parts, small welded constructions and fixtures, and the production of precise machined parts and components in low and medium quantities. We supply our products to a range of customers in the automotive, consumer electronic, household, furniture and automation industries in the EU-market.”

Eduard elaborates on the company’s impressive history: “The business was originally founded in 1951 as a tool making division of the ZTS Martin holding company, manufacturing tools and forms for the armament industry. At this time, the production and sales activities were strictly limited to the countries of the Eastern bloc, within the Council of Mutual Economic Assistance. After its breakdown at the beginning of the 1990s the military industry stopped being a priority, with many plants losing their markets and having to diversify their offerings.

“By the late 1990s many of these state-owned companies, including the military industry companies, had been privatised,” he continues. “In 1992 Viena International was established as a privately-owned company from the original tool making division of ZTS Martin. Later, in 2001 the company joined the Rejlek Metal and Plastics Group, initiating intensive development of its technical and organisational structures in preparation for an additional production programme – the stamping of metal parts. It is hoped that these developments will help us to penetrate new markets with large series production, and assure a better stability for the future of the company.”

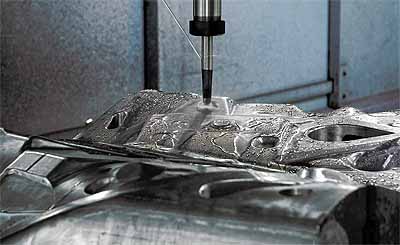

Being a member of the Rejlek Metal and Plastics Group enables Viena International to offer a comprehensive product portfolio developed and manufactured by a dedicated technical team. Production at the business is divided into three main categories – the design and production of stamping tools, the custom-made production of machine tools parts and components for machine producers, and the stamping and assembly of metal parts. To obtain the best possible results, the organisation uses the latest CAD/CAM pro engineer and Edge CAM technology during the design and development phases.

The company’s development programme and focus on innovative technology has seen it change from a parts manufacturer to a dedicated, customer-focused business in recent years. As this development continues, Eduard explains that the company will look to use different materials in its products: “In the near future we intend to begin the production of forms for the manufacture of plastic components. Initially we want to focus on selfsufficiency by using the parts that we already have in our assembly and steadily increasing the ratio of our own work, whilst decreasing the amount of purchased semi-products. After we fulfil our initial needs we will enlarge the number of our purchasers and adjust the production to suit individual customer needs.”

To maintains its high quality standards, Viena International continually invests in its production processes and facilities: “The constant enhancement of our production processes has ensured that we have obtained the ISO 9001: 2000 certificate for our quality management system for development, design and production of stamping tools and fixtures, the production of stamping parts with assembly, and the production of precise machine parts and components,” Eduard explains.

“Furthermore, we have achieved ISO 14001: 2004 for implementing and applying our environmental management system,” he continues. “We take our environmental responsibilities very seriously and care deeply for our local area. For example, last year we invested more than one million SKK in the liquidation of old waste, and around 680,000 SKK in new dumpsters for our facility. Additionally, to save electricity we have switched to gas heating, and plan to use solar energy for heating water in the coming years. This is an ongoing process and we intend to invest further in our internal ecological programmes in the future.”

As Eduard explains, Viena has very close connections with its local area, participating with many organisations in the region: “Our company realises its social responsibility and supports various local schemes and initiatives to improve the quality of life in the area. For example, we support the local theatre’s festival ‘Touches and Connections’ and the top Slovakian amateur theatres in the region, and are a partner of the Children’s House in Necpaly. Additionally, we work with the local cycling club, particularly Patrik Chlebo, the handicapped member of the Slovak national cycling team, and the Slovak Association for the hearing impaired.”

Eduard explains that working closely with local organisations such as schools is also beneficial for Viena International in terms of future employees: “We believe that the lack of qualified employees in our region will deepen in the coming years, which means that we seriously support the engineering educational facilities in the area. Therefore as much as we can we undertake many actions, such as supporting the region in social, cultural or sport to eliminate this negative phenomenon.

“For example, we work in co-operation with many of the educational institutions in the vicinity of Martin to encourage the education of qualified specialists that can find self-assertion in our company,” he comments. “When the company was founded we began co-operation with the secondary engineering school in Martin. This agreement now involves us designating the educational specialisation at the school, and providing the technical training within our company. This year, in conjunction with the Ministry of Education of the Slovak Republic and the Chamber of Commerce in Zilina, the graduates in the professional toolmaker course took their final exams at our premises. Furthermore, we commenced co-operation with the Faculty of Mechanical Engineering of the Zilina University.”

With its heritage and experience in the industry, combined with its reputation, both locally and internationally, the future currently looks very promising for Viena International. Slovakian industry is going from strength to strength – the country has the highest ratio of manufactured cars per capita in the world, and the recent arrival of major companies such as Volkswagen, Kia, Sony and Samsung is helping to revive the heavy engineering industry in the region.

In the coming years, the business intends to add new production programmes to its portfolio and enter new markets, whilst further enhancing the co-operation with schools and educational facilities in the region. Eduard concludes: “We aim to continue the development of the important parameters for success, whether they be technical, financial or personal, whilst improving our turnover and our products annually.”

Viena International

Products: Stamping and machine tools

Sites: Slovakia

Employees: 550

www.viena.sk