Barton Malow

When the University of Northern Arizona set out to hire a construction manager to renovate the J.L. Walkup Skydome, school officials did their homework thoroughly. Not content to simply select the lowest bidder, the university opted for a construction manager at-risk contract wherein the contractor is selected based on a set list of qualifications. Additionally, the project price is set at a guaranteed maximum price, which reduces the owner’s financial risk on the project.

When the University of Northern Arizona set out to hire a construction manager to renovate the J.L. Walkup Skydome, school officials did their homework thoroughly. Not content to simply select the lowest bidder, the university opted for a construction manager at-risk contract wherein the contractor is selected based on a set list of qualifications. Additionally, the project price is set at a guaranteed maximum price, which reduces the owner’s financial risk on the project.

The school chose Barton Malow, Tempe, Ariz., as the construction manager of the project. “We have a lot of experience building sports stadiums as well as renovation projects,” says Jason Mullins, project manager. “It was a good fit for our abilities.”

Since 1924, Barton Malow has built a variety of structures across the United States for both public and private clients. From government facilities to educational buildings to industrial plants, the company’s reputation for performing quality work has garnered repeat business from several clients.

Recent projects include a General Motors plant, San Luis Potosi, Mexico; the Peninsula Regional Medical Center, Salisbury, Md.; and the Shirley Clements Mewborn Field, Atlanta – the first LEED Gold-certified ballpark in the United States.

Always prepared to take on challenging projects, it was not unusual for Barton Malow to survey the Walkup Stadium prior to interviewing for the project.

“Since we’d completed several stadium projects, I believe we offered a certain perspective that benefitted the university,” Mullins declares. “We also understood the university’s need to build in flexibility while maintaining the existing structure.”

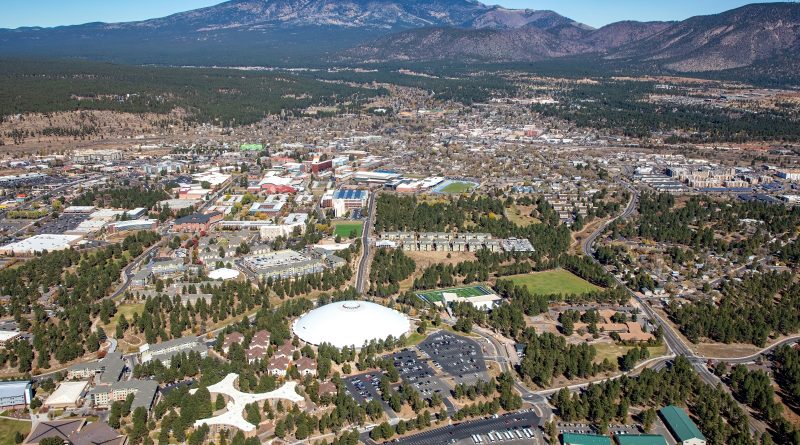

The 268,000-square-foot multipurpose arena, constructed in 1976, is undergoing renovations primarily to meet current ADA and fire life safety codes. Included in the plan are ADA code-compliant seating, elevators, restrooms and egress improvements. Also, office space, locker rooms, concession and retail areas, and storage, as well as electrical, mechanical and water systems will be updated.

One remarkable feature of the existing building is the clear span timbered dome that the university wanted to keep intact. Not a LEED-certified project, this project adheres to some green standards because the university was able to reuse the structure itself.

Communication is Key

As with any project Barton Malow is involved in, the general contracting team collaborated with the owner and architect during the design phase. “Communication is a big key to the success of projects,” Mullins notes. “Especially fast-track projects like this one.” Though they were able to begin preliminary work in August 2010, the demolition phase couldn’t begin until after Dec. 20, 2010. He adds that the remainder of the work must be completed by Sept. 10, 2011 – in time for the first football game of the season.

Barton Malow is a firm believer in using building information modeling (BIM), particularly in renovation projects such as this one. “BIM is crucial in a renovation,” Mullins says. “We were able to survey the mechanical, electrical and ductwork systems and were able to solve any conflicts before construction even began.” He says it also provides the crew members with a model that they can refer to to stay on track with the project.

One way Barton Malow is accelerating the construction pace is by multitasking. “We’re currently operating four different projects in the dome simultaneously,” Mullins notes. “Each is independently crewed and built as opposed to having one single crew complete each project and move on to the next.”

Mullins claims this project has benefited greatly from the strong lines of communication between the crews, the owner and the architect. “When we’ve run into any issues, we’ve been able to come up with solutions quickly through collaboration.”

One such issue arose when crews attempted to install a glass handrail that was very challenging to build. “The handrail was meant to be surface-mounted,” Mullins says. “By working with the supplier, the architect and the university, we were able to reconfigure the design to recess the handrail into the slab.” He maintains the resulting design provided a better reveal and was simpler to construct, yet maintained the architectural aesthetic.

Involving the Community

Mullins asserts that Barton Malow’s strong relationships with subcontractors and vendors are also a major key to the success of the project. “All of our subcontractors went through our prequalification process to make sure they could meet the demands of the job,” he says. “In this case, we advertised locally to involve the community in the project.” Barton Malow’s key partners include Kortman Electric and Encore Steel Inc. The project is on track for completion in time for NAU’s first football game of the 2011 season.